Buried reflux casing type circulating geothermal heat exchanger and use thereof

A heat exchange device, sleeve-type technology, applied in the field of buried return flow sleeve-type circulation geothermal heat exchange device, can solve the increase of ground hole drilling costs and related material costs, small footprint of spiral coils, and stable system In order to achieve the effect of expanding the scope of project adaptation, reducing the amount of construction and reducing the cost of pile foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

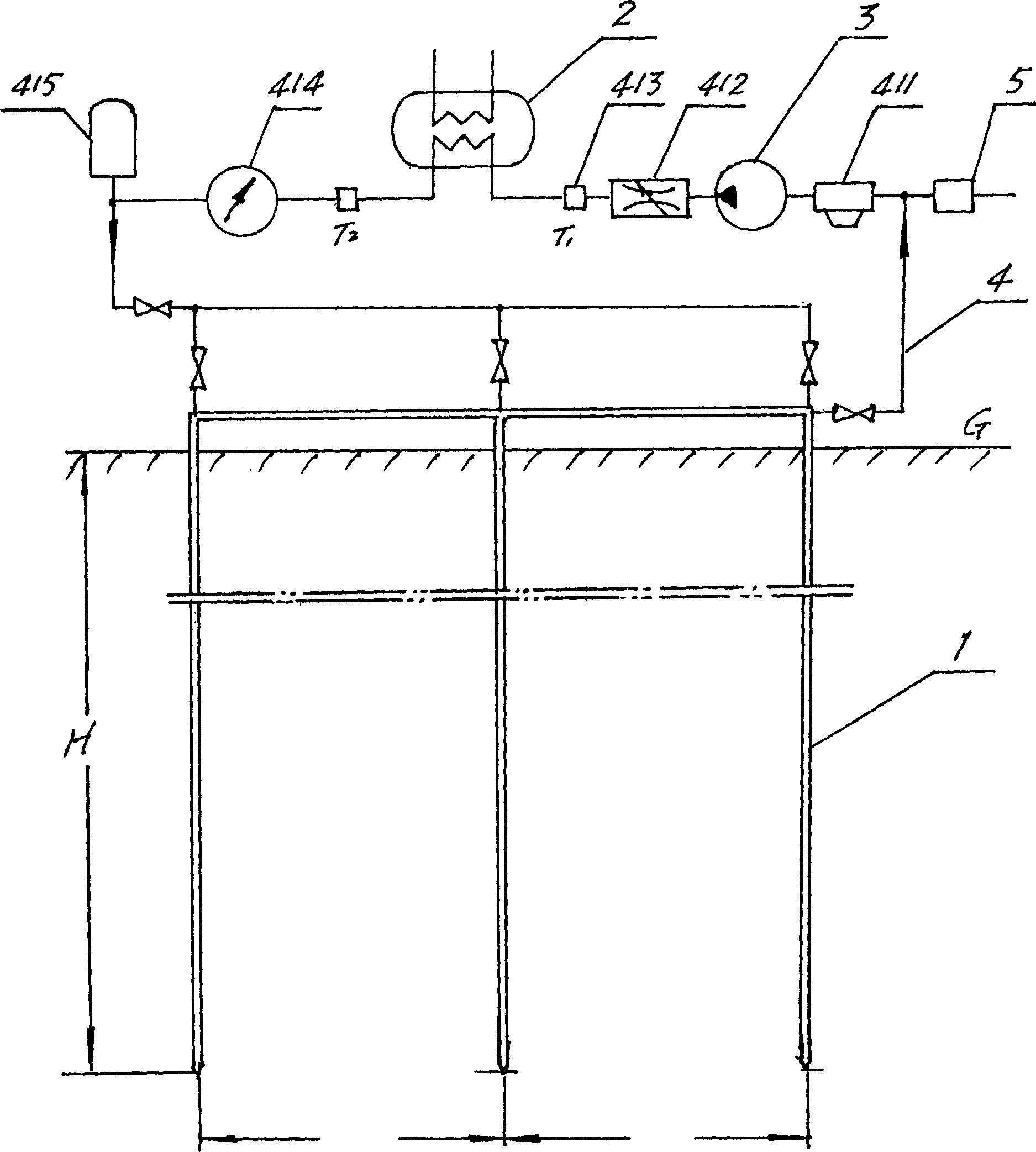

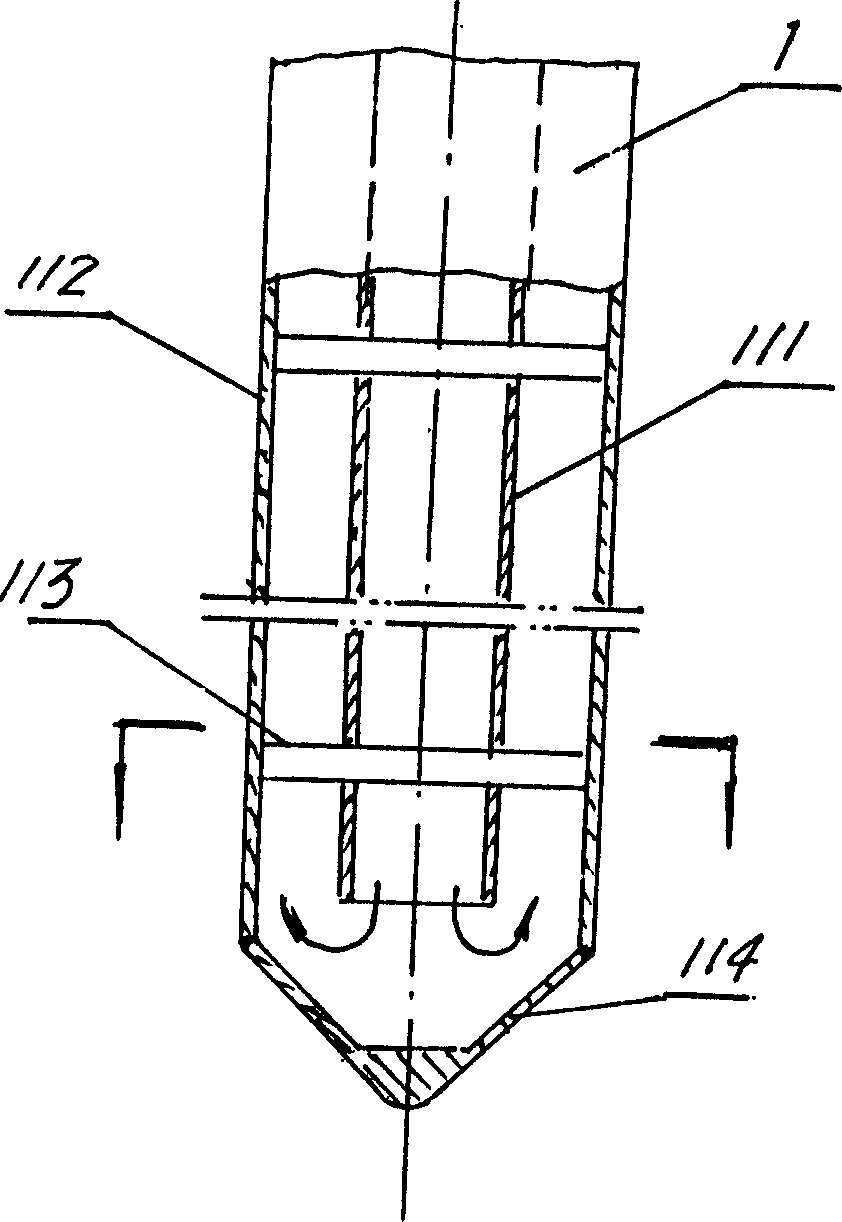

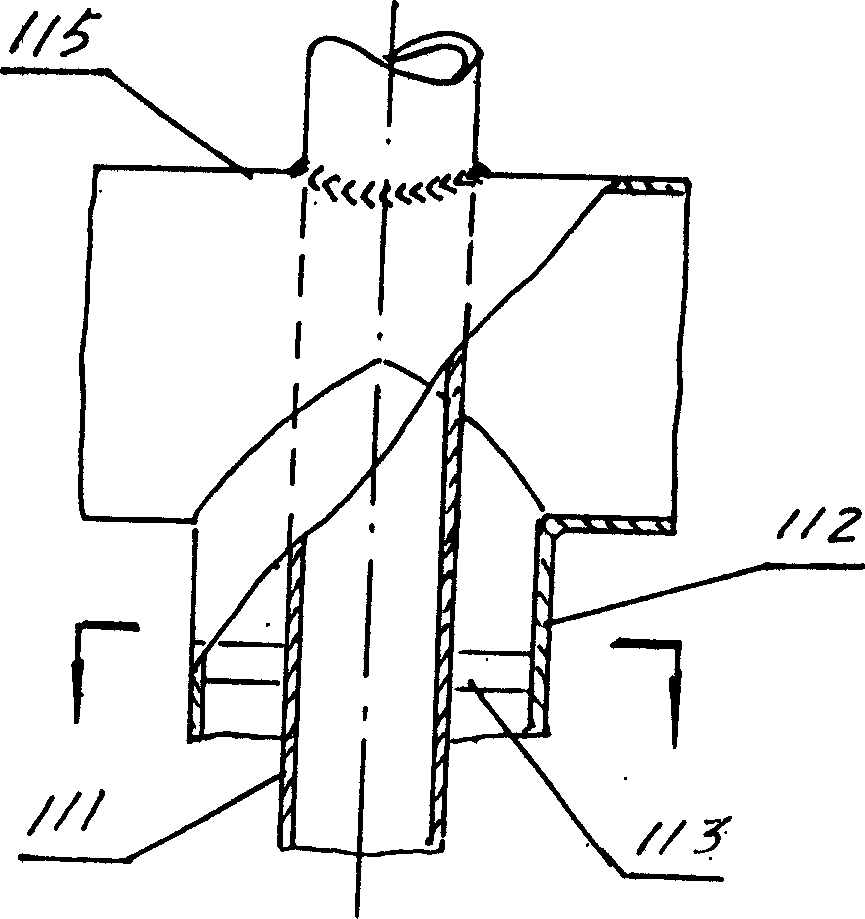

[0014] according to figure 1 As shown, one of the embodiments of the buried return casing type circulating geothermal heat exchange device of the present invention is composed of a buried pipe 1, a heat exchange unit 2, a circulation pump 3, a circulation pipeline 4, a moisturizing seepage pipe 5, and a heat-carrying medium. . Among them, the buried pipe adopts such as figure 2 The buried return sleeve with the inner pipe fixed in the outer pipe as shown has a structure including an inner pipe 111, an outer pipe 112, a holder 113 and a cone top 114 welded to the outer pipe. In addition, the buried The ground pipes are also connected to each other via a manifold 115 , and the circulation pipeline 4 includes a decontamination device 411 , a flow regulating valve 412 , a temperature sensor 413 , a flow meter 414 , and an accumulator 415 . Buried pipes, heat exchange units, circulation pumps, circulation pipelines, etc. constitute a closed geothermal heat exchange loop.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com