Novel process for manufacturing retained mandrel for continuous rolling of steel pipe

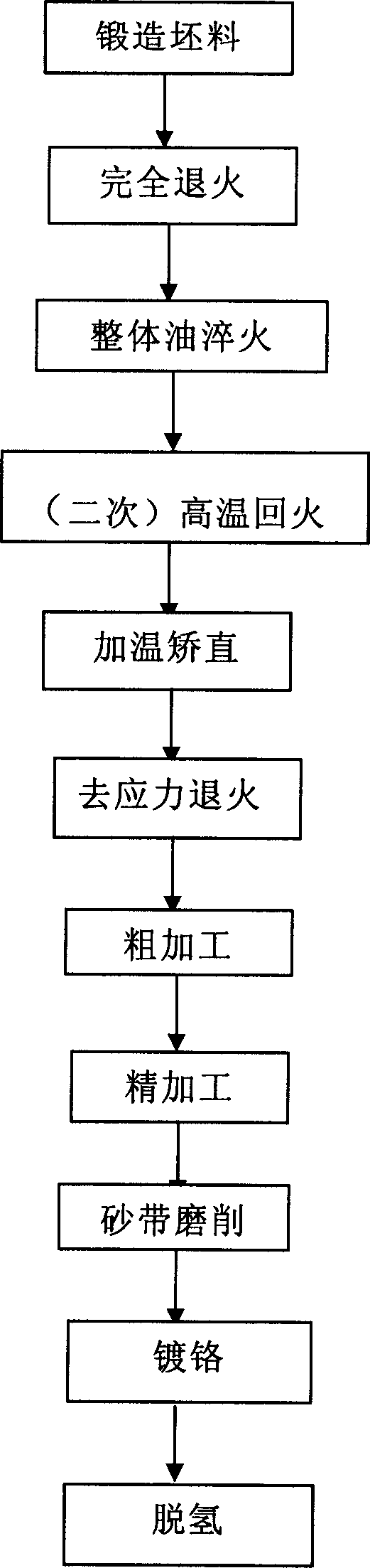

A technology for restricting mandrels and new processes, applied in manufacturing tools, other manufacturing equipment/tools, metal rolling, etc., can solve the problems of low yield of mandrel blanks, complicated manufacturing processes, and long manufacturing cycles, etc. To achieve the effect of reducing the difficulty of processing and manufacturing, improving the effective operation rate and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

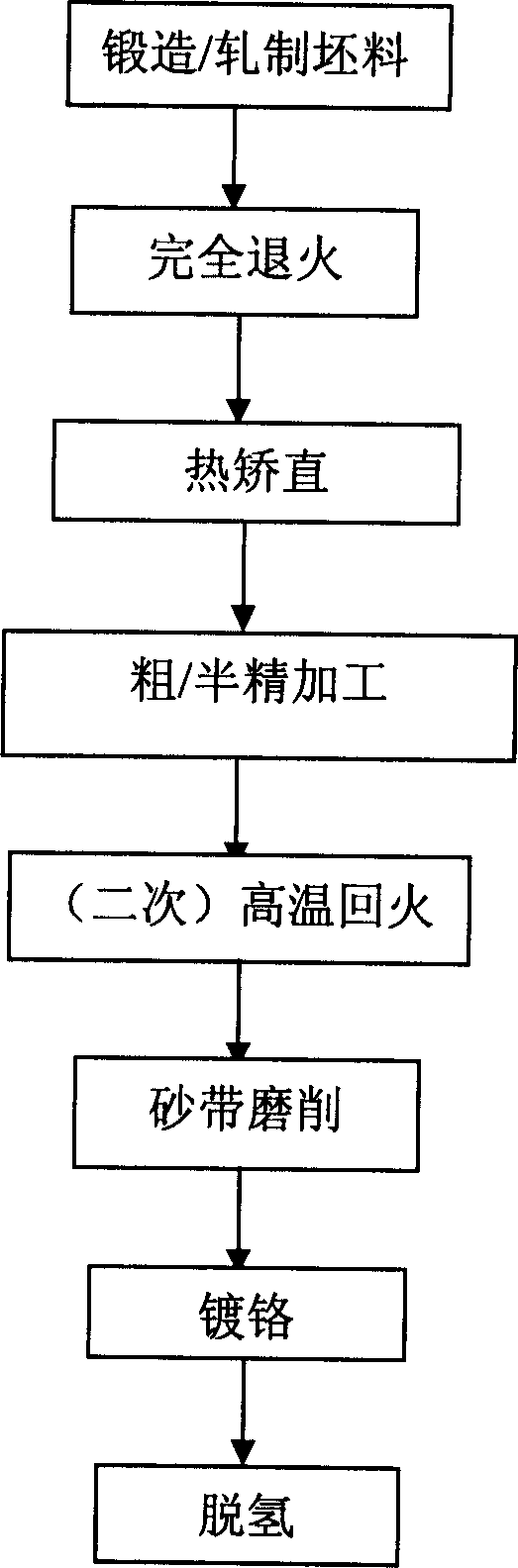

[0038] In order to help understand the present invention, typical embodiments of the present invention will be described in detail below in conjunction with related drawings.

[0039] See image 3 , the process flow of a typical embodiment of the present invention is: forging blank → complete annealing → thermal straightening → adopting cyclone lathe to carry out rough / semi-finishing → dual frequency quenching → (secondary) high temperature tempering → abrasive belt grinding → chrome plating → Dehydrogenation.

[0040] The first step is to obtain forging / rolling blanks. For the sake of economy, unless it is a mandrel with a large outer diameter, forging billets are used because the forging ratio / rolling ratio cannot be satisfied, and rough rolling billets with better straightness, small ellipticity and better appearance quality should be used as much as possible. In this embodiment, a cast steel ingot of 10.8 tons is used, and a Ф183mm×20m mandrel blank is obtained after rough...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com