Monitoring marking layout for microlens baking process

A technology of micro-lens and marking, which is applied in the direction of lens, exposure device of photo-plate making process, exposure equipment of micro-lithography, etc. It can solve the problems of difficult reflective pattern, poor efficiency, large error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

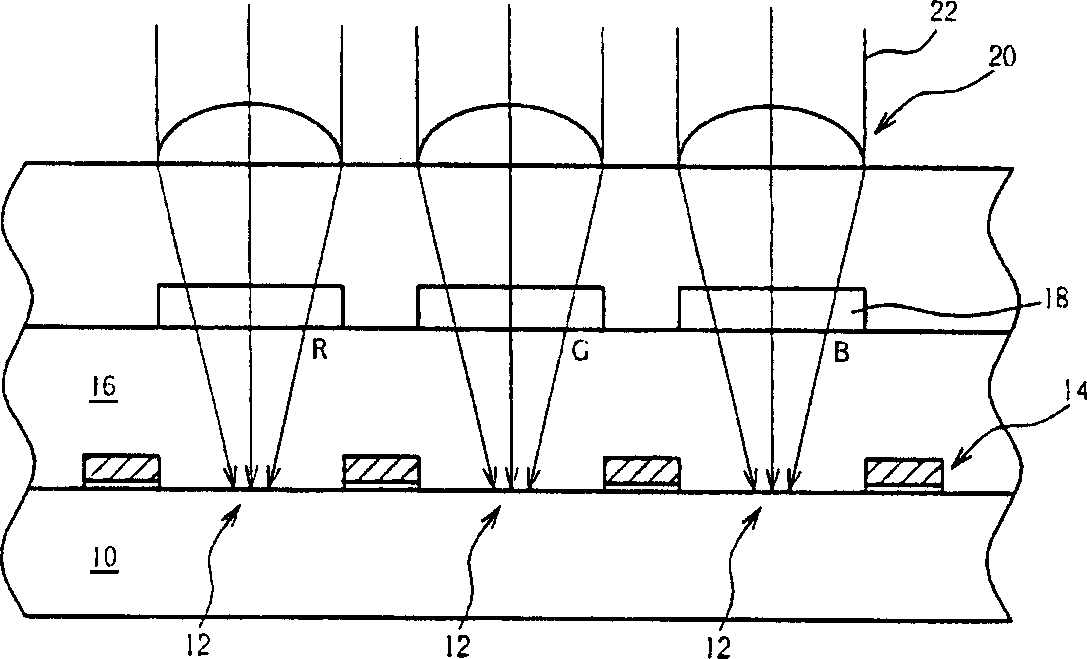

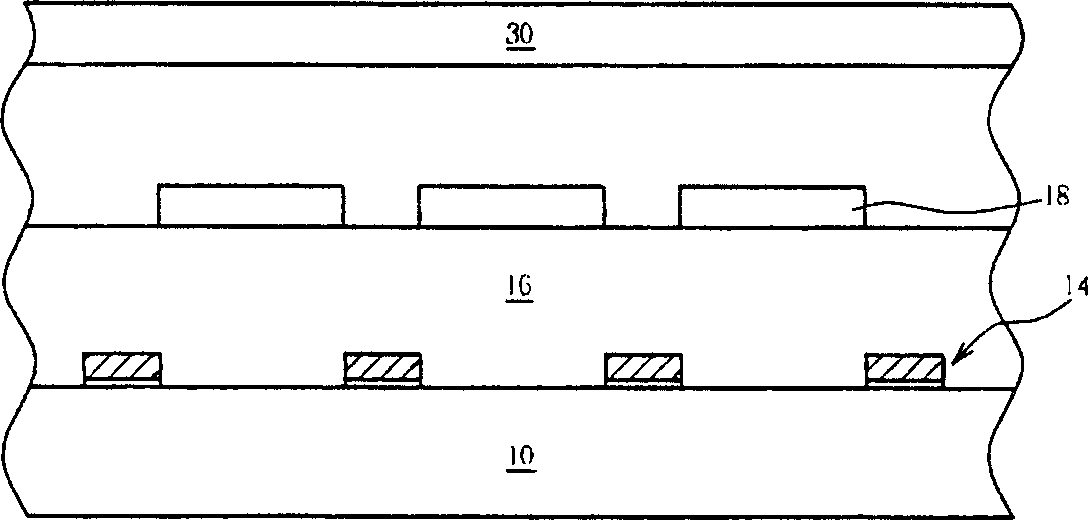

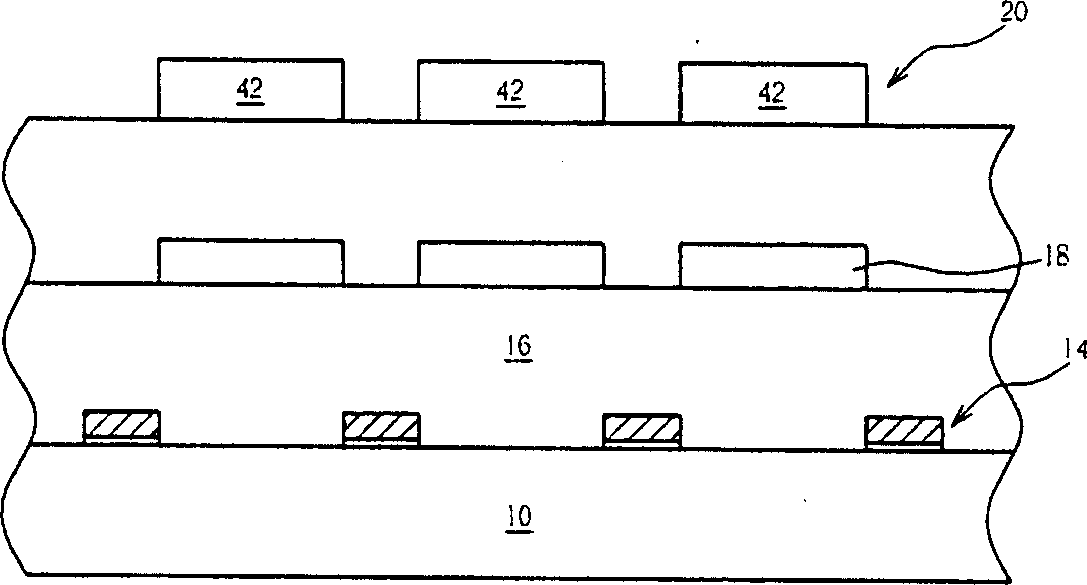

[0032] see Figure 5 , which shows the layout of the monitoring marks and the top view of the microlens array that can be used to check the baked state of the microlens in the preferred implementation of the present invention. Such as Figure 5 As shown, the microlens array 20 is formed in the active circuit area 101 with a plurality of unbaked photoresist blocks 42 . In the present invention, the monitoring mark layout 100 for checking the baked state of the microlens can be formed in the scribe area 102 and defined simultaneously with the photoresist block 42 . The size of the layout shown in the figure is for reference only.

[0033] According to this preferred embodiment, the monitoring mark layout 100 for checking the baked state of the microlens can be a U-shaped pattern, including two vertical line patterns 110 and 120 arranged in parallel to each other, and a horizontal line pattern 130 connecting the aforementioned two vertical lines. Line patterns 110 and 120 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com