Circuit board of electronic device and mfg method thereof

A technology of electronic devices and circuit boards, which is applied in the direction of assembling printed circuits, circuits, and printed circuit components with electrical components, and can solve problems such as limiting the practicality of circuit boards 1, increasing costs, and being unable to connect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

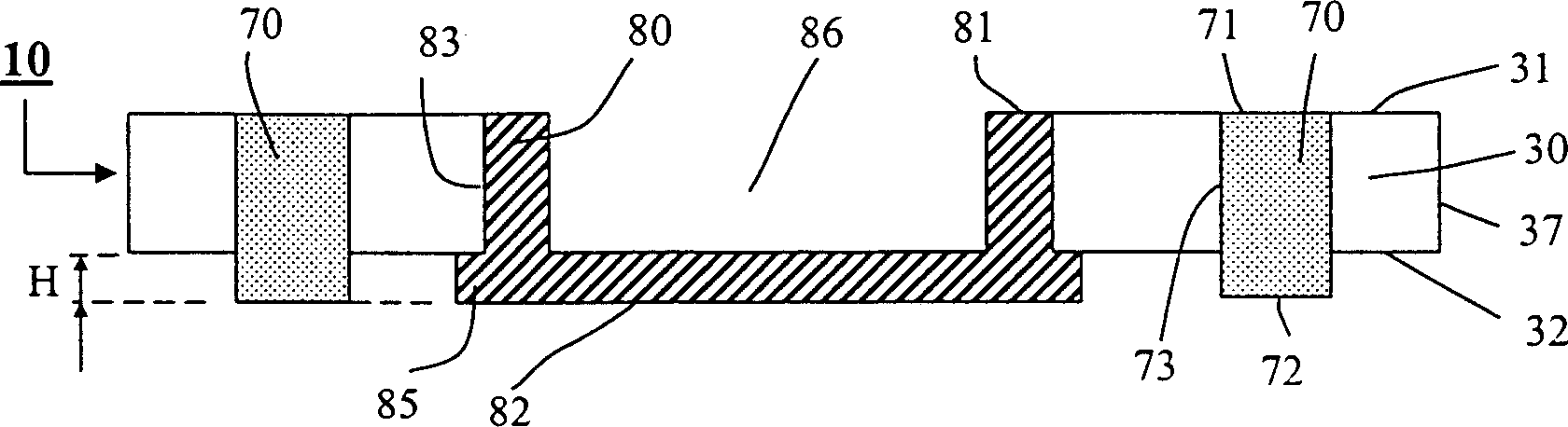

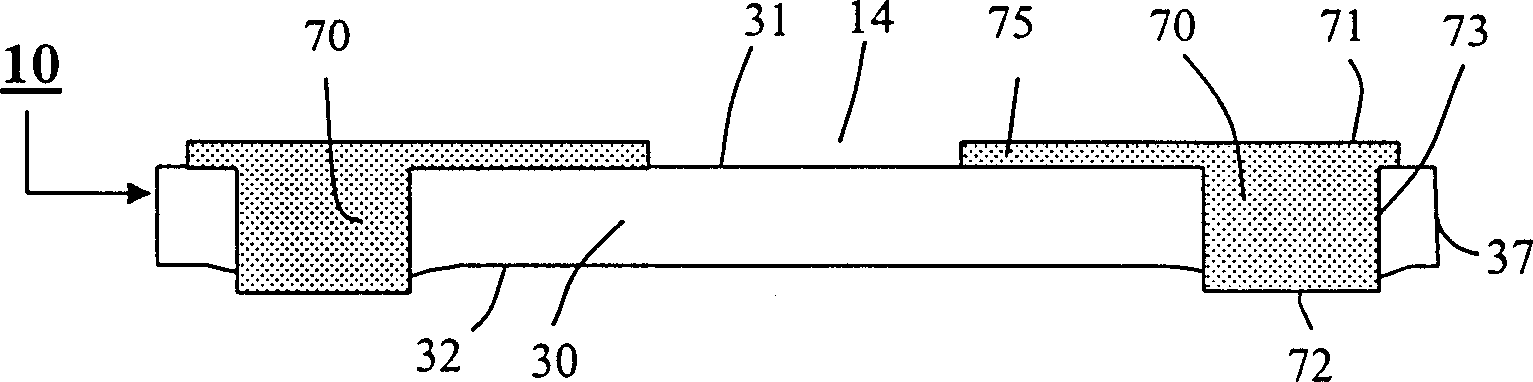

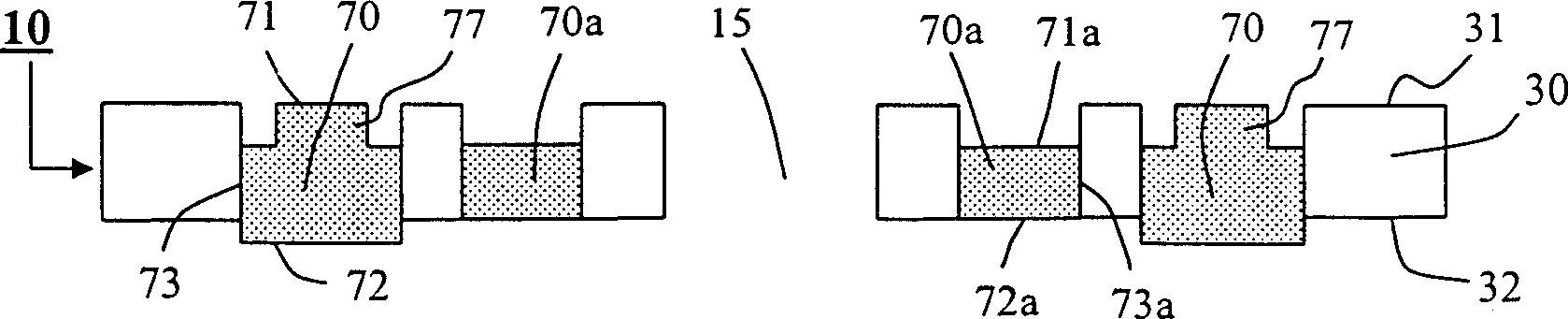

[0019] The first type of circuit board of the present invention is the basic structure of the present invention, wherein, the conductor is implemented as a solid solid state (solidstate), and its structure and function are now described in detail according to the following accompanying drawings:

[0020] Such as Figure 1A As shown, a circuit board 10 provided by the present invention includes: an insulator 30 having a first upper surface 31 , a first lower surface 32 and side edges 37 . Two first conductors 70, each first conductor 70 has a first upper surface 71, a first lower surface 72 and a first side 73, the first side 73 is covered by the insulator 30, and the first conductor 70 is first upper The surface 71 and the first lower surface 72 are respectively exposed on the first upper surface 31 and the first lower surface 32 of the insulator 30 for power supply connection, wherein the first lower surface 72 of the first conductor 70 protrudes from the first lower surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com