Tapping screw making method

A manufacturing method and technology of self-tapping screws, which are applied in the direction of elements with teeth, gear teeth, belts/chains/gears, etc. The effect of long mold life and reduced mold loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

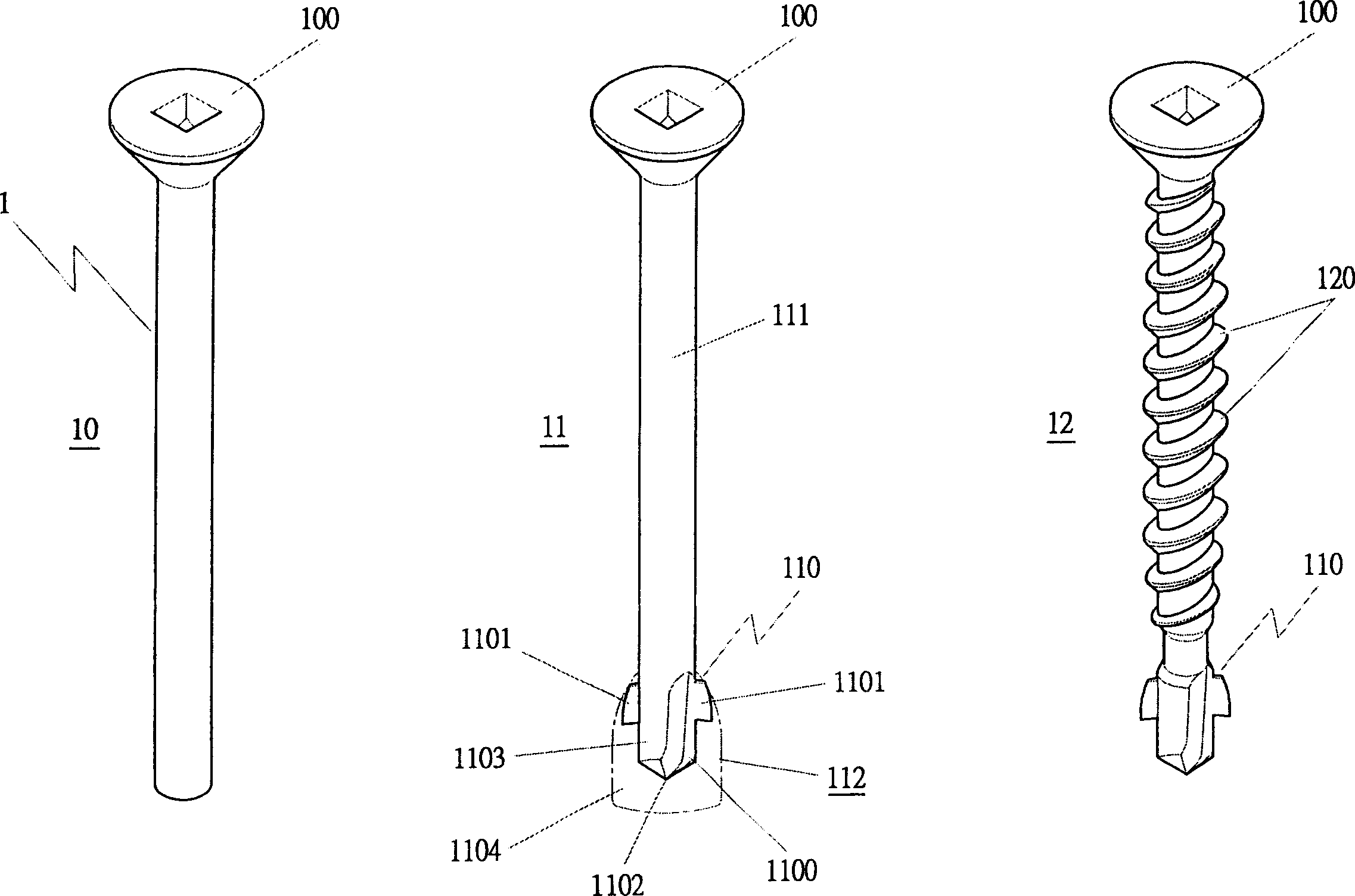

[0028] Such as image 3 , Figure 4 Shown, the present invention comprises the steps:

[0029] Preparing the primary blank: First, cut the metal raw material according to the required length to obtain a metal rod-shaped primary blank.

[0030] Cap forming: the primary blank is placed in the first forming mold, and the primary blank is punched with the cap 20 by using the first forming mold to produce the first blank 2 with the cap 20 .

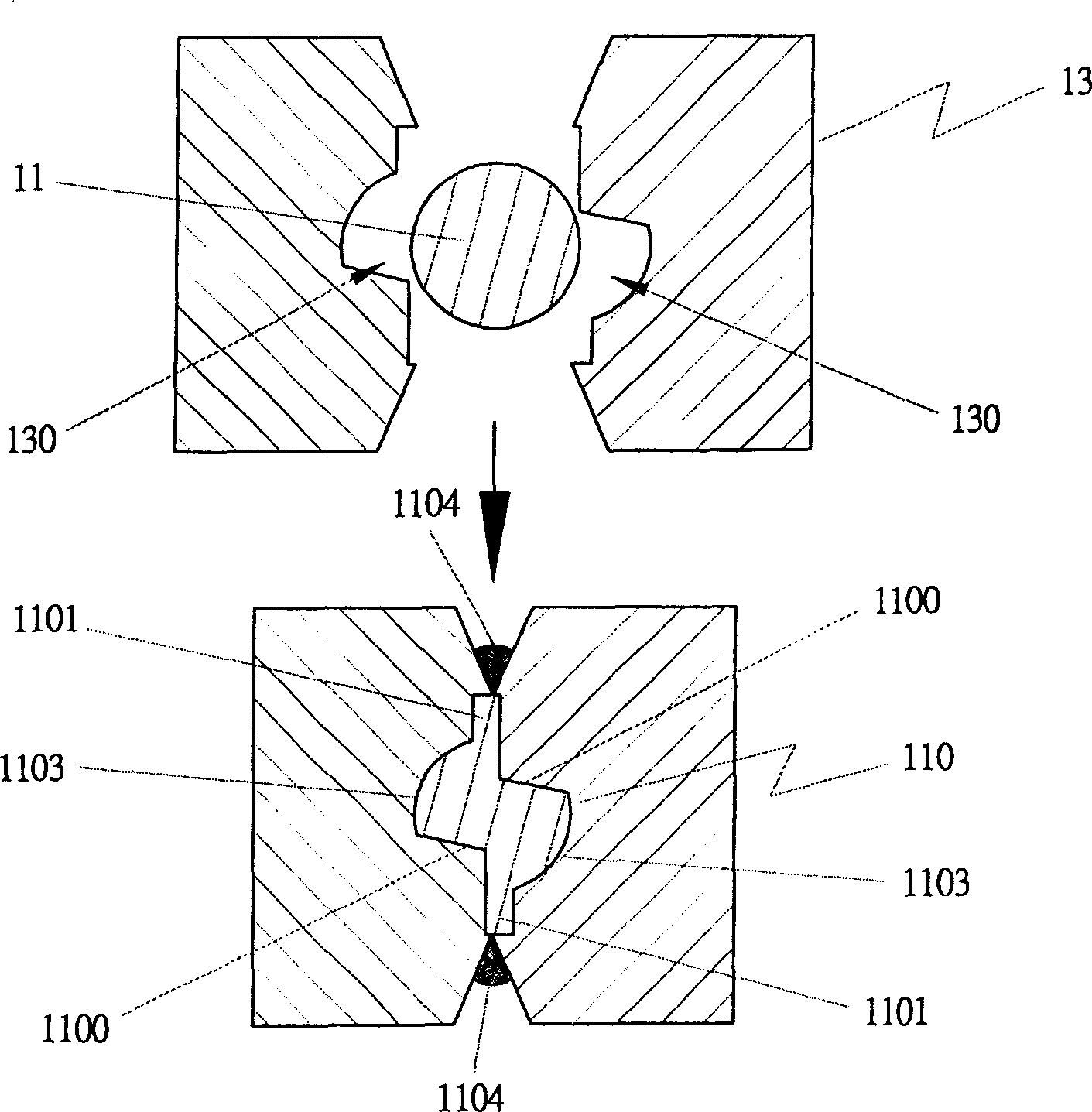

[0031] Tail molding: as Figure 4 , Fig. 5, shown in Fig. 6, the first blank material 2 is inserted in the second molding die 3A, utilizes the die groove 3A0 of the second molding die 3A to punch the other end of the first blank material 2 to form a The tail portion 30 of the diameter of the stem portion 31 is like the second stock 3 of the flat tail portion 30 , and the width of the flat tail portion 30 is greater than the diameter of the stem portion 31 . The second blank 3 in the tail forming step is only punched into the molding tail 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com