Laser rapid-forming method based on contour scanning of coated powder materials

A technology of laser rapid prototyping and powder materials, which is applied in laser welding equipment, instruments, electrical digital data processing, etc., can solve the problems of low strength and inability to process powder materials, and achieve high density and strength, forming speed and efficiency Improvement, the effect of high surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

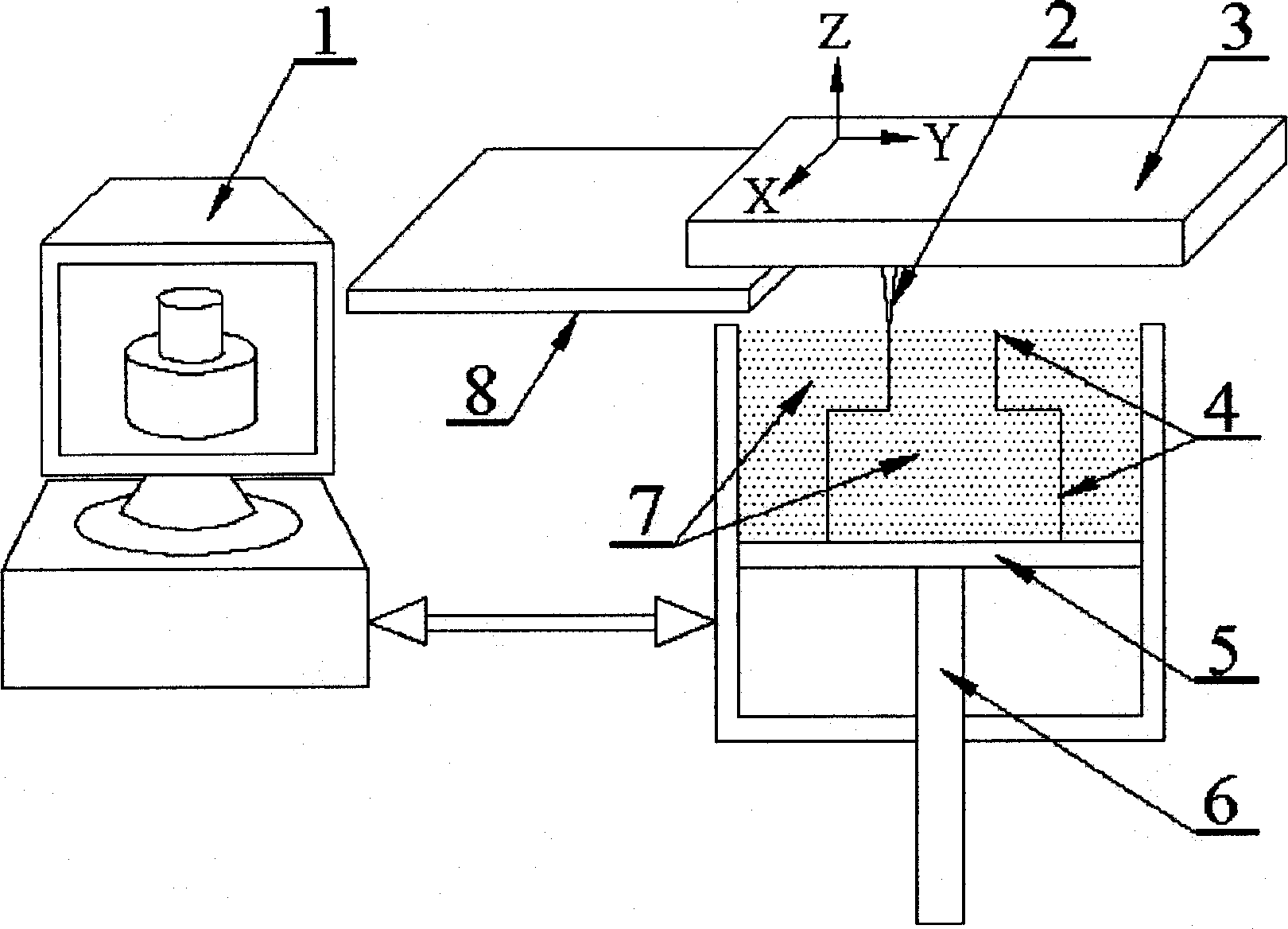

[0027] Embodiment 1: Manufacture "8" font entity

[0028] Firstly, the modeling design of the "8"-shaped three-dimensional CAD model is completed in the computer 1, and then layered in the Z direction, with a layer thickness of 0.6 mm, and the contour line information of each layer is extracted. Turn on the laser and adjust the power of the laser, and start the motion control system. Lay a layer of thick film-coated powder material on the workbench 5, and the laser beam 2, under the control of the computer 1, scans the two-dimensional profile of the layer of powder material in the shape of "8", so that the two-dimensional profile of the current layer The film-coated powder material on the line heats up until it loses its sintering performance, and then the computer controls the piston 6 to descend by 0.6 mm to carry out the next layer of powder spreading and contour scanning until the three-dimensional contour 4 required for molding is scanned. The whole coating powder materi...

Embodiment 2

[0029] Example 2: Manufacture of bevel gears

[0030] Firstly, the modeling design of the three-dimensional CAD model of the bevel gear is completed in the computer 1, and then layered in the Z direction, with a layer thickness of 0.6 mm, and the contour line information of each layer is extracted. Turn on the laser and start the computer control system. Lay a layer of thick film-coated powder material on the workbench 5, and the laser beam 2 scans the two-dimensional contour of the bevel gear on the layer of powder material under the control of the computer, so that the powder on the two-dimensional contour line of the current layer The material is heated up until it loses its sintering properties, and then the computer controls the piston 6 to descend by 0.6 mm to carry out the next layer of powder spreading and contour scanning until the three-dimensional contour 4 required for molding is scanned. The coating powder material 7 is preheated on a heating plate for 5 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com