Organic electroluminescence display and its producing method

A technology for electroluminescent display and manufacturing method, which is applied in the direction of electroluminescent light source, electric light source, light source, etc. It can solve the problems of affecting the yield rate, unstable short circuit or potential short circuit, waste of integrated circuit driver chips, etc., so as to avoid waste , Improve yield rate and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1. Aging by constant forward current: a forward current is applied continuously for 30 minutes, and the current density is 2.5 mA / cm2.

[0049] 96 organic electroluminescent devices were produced. After aging with forward current, 6 grains of negative and positive electrode short-circuit defects were detected, accounting for 6.25%. 24 modules were bonded by adding an integrated circuit driver chip. During the aging process of the modules, 12 short circuits were detected between the positive and negative electrodes, accounting for 50%.

Embodiment 2

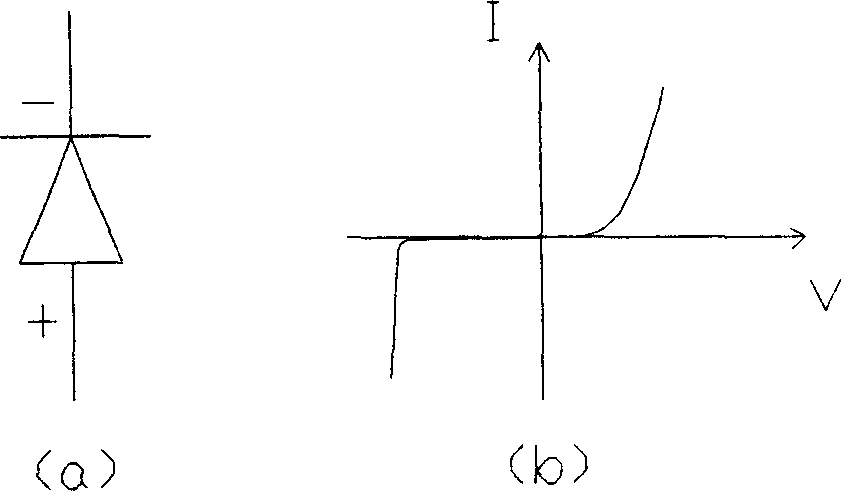

[0050] Embodiment 2: Aging by combination of forward pulse and reverse pulse: apply a forward current with a current density of 160mA / cm2 for 15.6ms continuously, and then apply a reverse voltage -20V with a frequency of 1Hz for 984.4ms continuously, for a total of 30 minutes.

[0051] 144 organic electroluminescent devices were produced. After using combined pulse aging, 11 grains of negative and positive electrode short-circuit defects were detected, accounting for 7.64%. 27 modules were bonded by adding integrated circuit driver chips, and 1 module was found to be short-circuited between the positive and negative electrodes during the aging process of the modules, accounting for 3.7%.

Embodiment 3

[0052] Embodiment 3. Aging by constant forward current: applying a forward current with a current density of 2.5 mA / cm2 for 4 hours continuously.

[0053] 432 organic electroluminescent devices were produced. During the aging process, a total of 32 short-circuit defects appeared, one of which was eliminated, accounting for 3.1% of the short-circuit defects, and the remaining 31 short-circuit defects appeared, accounting for 7.18% of the total. 344 modules were bonded by adding integrated circuit driver chips, and 144 short-circuit defects of positive and negative electrodes were detected during the aging process of the modules, accounting for 41.86%. In general, the defective rate of negative and positive electrode short circuit accounted for 40.51% of the total.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com