Specific reinforced concrete frame structure

A frame structure, ultra-high-strength concrete technology, applied in building construction, construction, etc., can solve the problems of waste materials, occupying a large area, and difficult construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

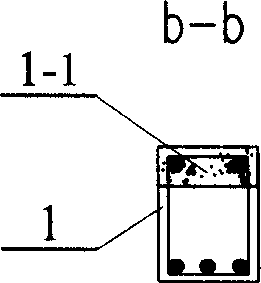

[0005] Specific implementation mode one: (see Figure 1-Figure 4 ) This embodiment consists of a frame beam 1, a frame column 2 and a frame node 3, the cross-sectional compression zone of the frame beam 1 is composed of high-strength or ultra-high-strength concrete, and the cross-sectional tension zone of the frame beam 1 is composed of ordinary concrete; the frame The column 2 has a built-in high-strength or ultra-high-strength concrete core column 2-1, and the frame node 3 is composed of high-strength or ultra-high-strength concrete.

specific Embodiment approach 2

[0006] Specific implementation mode two: (see Figure 1-Figure 4 ) The difference between this embodiment and specific embodiment 1 is that the mid-span compression zone 1-1 of the frame beam 1 is high-strength or ultra-high-strength concrete; the support compression zones 1-2 at both ends of the frame beam 1 are high-strength or ultra-high-strength concrete concrete. Other compositions and connections are the same as in the first embodiment.

[0007] The implementation steps of the different-strength concrete frame structure of the present invention are: 1. pour the core column 2-1 first, and when the concrete of the core column 2-1 is hardened, support the formwork to tie the ribs and pour ordinary concrete on the periphery to form a built-in high-strength or Reinforced concrete frame column 2 of ultra-high-strength concrete core column 2-1; 2. Pouring high-strength or ultra-high-strength concrete frame joint 3; 3. First pouring high-strength or ultra-high-strength concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com