Novel shaft sleeve of textile machinery

A technology of textile machinery and textile machines, applied in the field of new shaft sleeves, which can solve problems affecting the quality of sliver, heat and oil leakage of shaft sleeves, and wear and tear of shaft heads, so as to improve the uniformity and quality of sliver thickness, improve bending strength, The effect of preventing the entry of flying flowers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

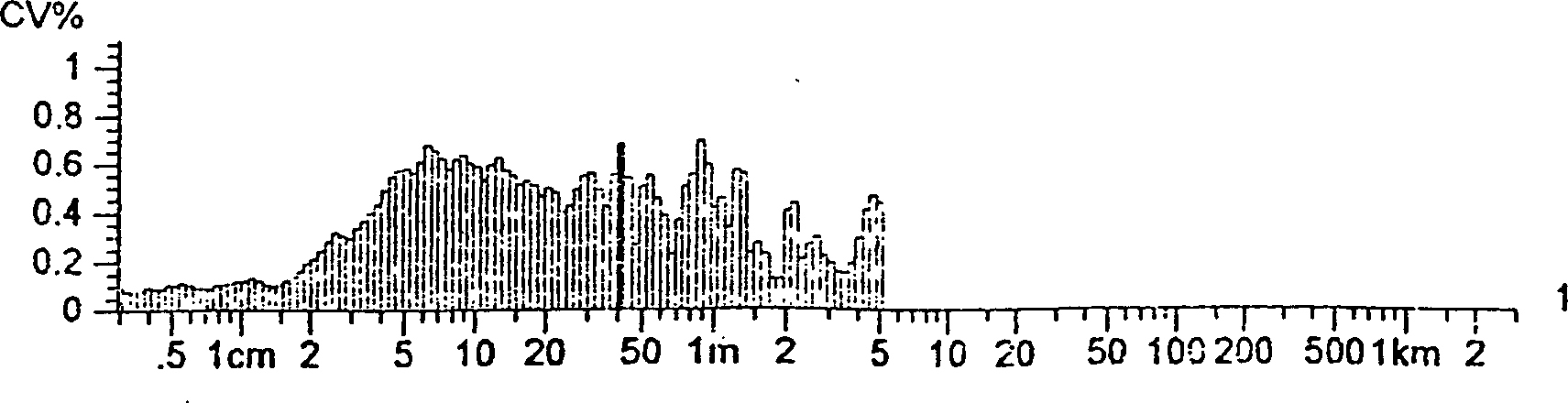

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the embodiments of the accompanying drawings.

[0018] Such as figure 1 As shown, the new shaft sleeve of textile machinery includes a mandrel 3 installed on the textile machine. The two ends of the mandrel are close to the middle of the force. At the same time, the diameter of the cylindrical shaft head is increased to increase the bending strength of the mandrel to avoid bending deformation. The conical body is provided with a tapered inner ring 11 which is combined with a conical surface and fastened by bolts 12 to form a tight fit. The stepped sleeve 4 with interference fit makes the mandrel, the tapered inner ring, the stepped sleeve and the bolts form a rotating body relative to the bearing shell, and forms a fully enclosed structure through the finishing process to prevent flying flowers from entering.

[0019] The bearing shell 10 and the tapered inner ring 11 are made of bearing steel,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com