Arc welding control method and arc welding device

A control method and technology for arc welding machines, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of reducing welding operation efficiency, deteriorating price-performance ratio, etc., and achieve the effect of reducing welding voltage and expanding application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

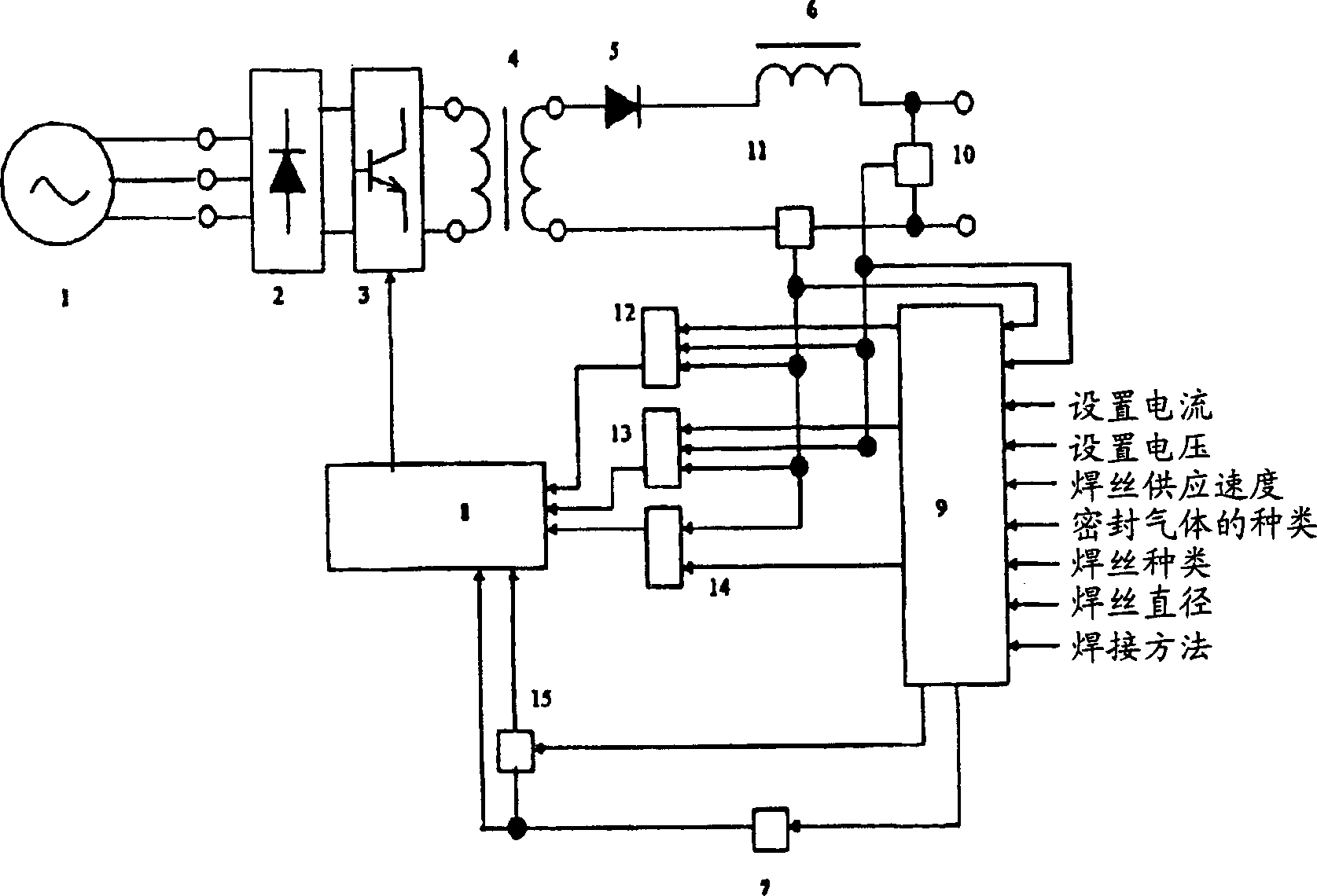

[0036] exist figure 1 Among them, the reference number 1 represents the mains AC power supply, which is used to input the AC current; 2 represents the primary rectification part, which is used to rectify the input current input from the mains power supply; 3 represents the switch element weldment, which is used to control Welding output; 4 represents the transformer, which is used to transform the voltage while isolating the power supply; 5 represents the secondary rectification part, which is used to rectify the secondary output of the transformer; 6 represents the reactance coil (DCL); 7 represents the short circuit arc determination part, It is used to determine whether the welding state is in the short-circuit period or the arc period; 8 indicates the driving part; 9 indicates the setting part, which is used to set various parameters according to the setting bar weldment, the setting bar weldment includes the set current, the set Voltage, supply of electrode, type of seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com