Chip-style radiating module and radiating method thereof

A technology of heat dissipation module and heat dissipation method, which is applied in the direction of electrical components, electric solid devices, circuits, etc., and can solve problems such as easy condensation, interference, and discounted heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

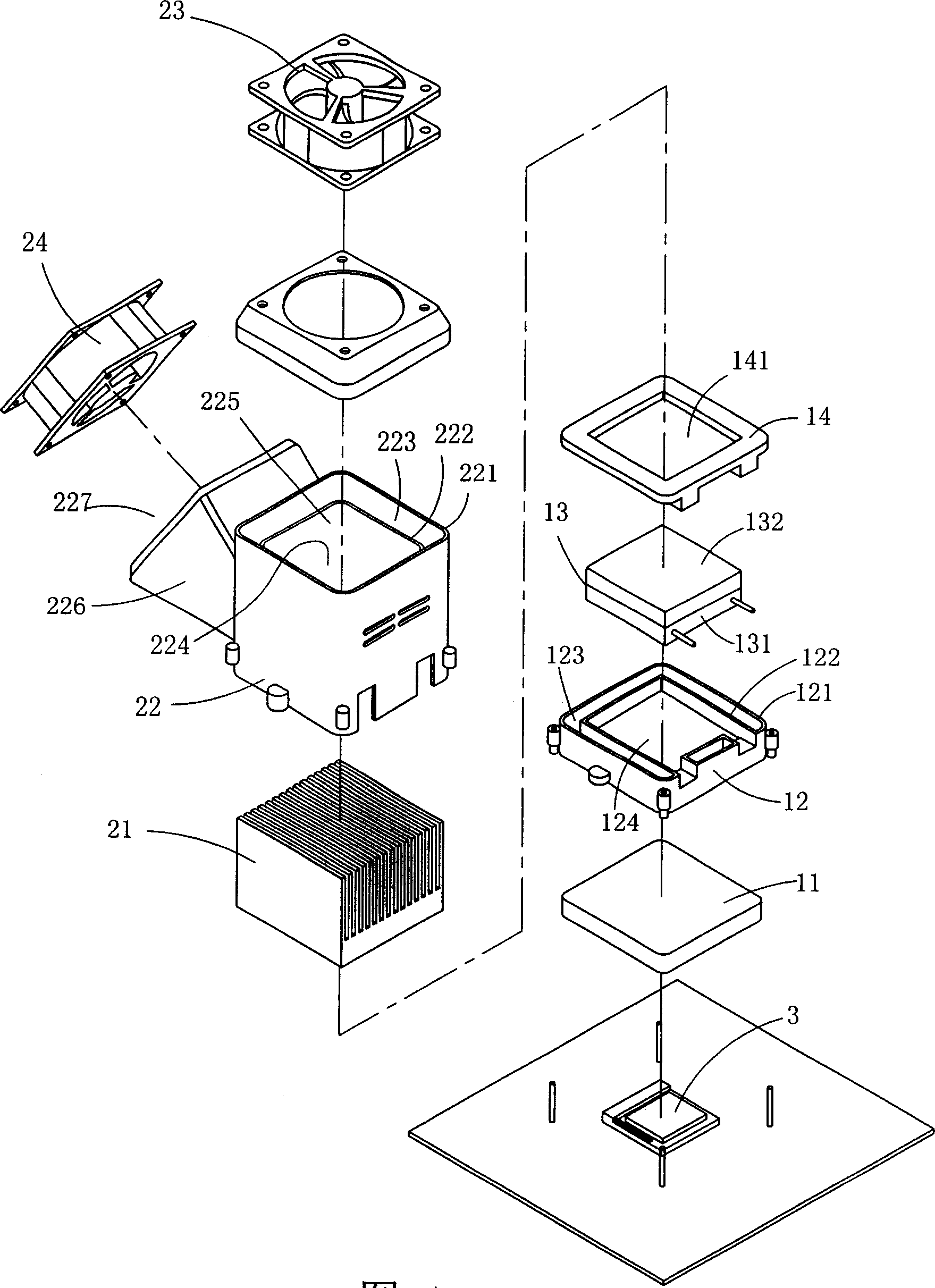

[0017] see Figure 1 to Figure 4 , is a perspective view of a preferred embodiment of the chip cooling module of the present invention, the chip cooling module in the embodiment is used to dissipate the heat generated by a central microprocessor 3 (CPU).

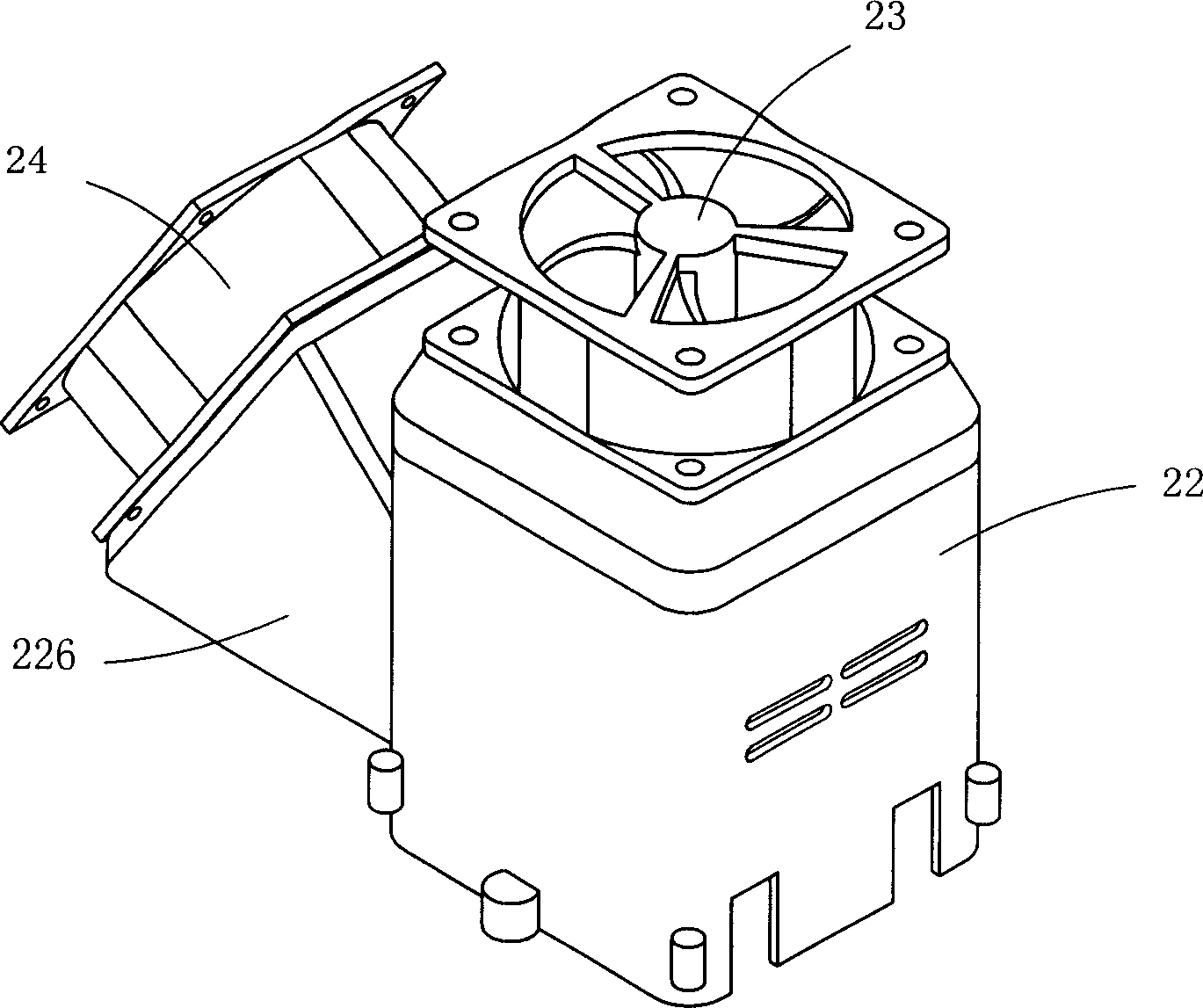

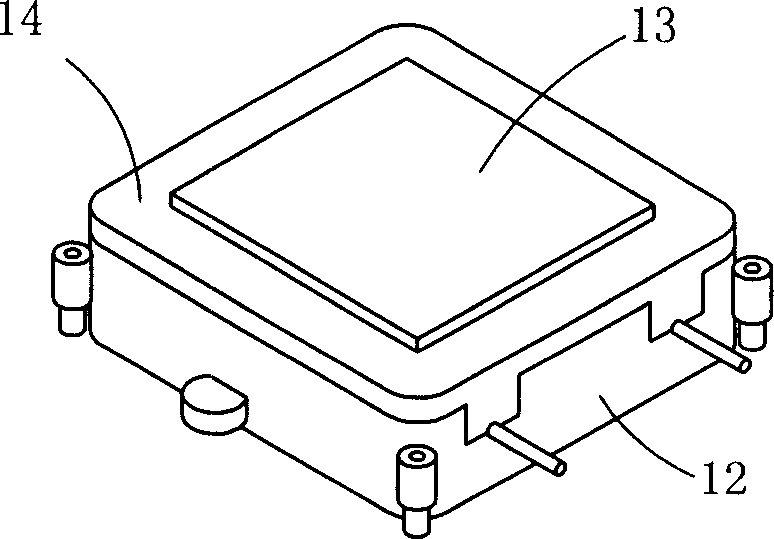

[0018] The wafer heat dissipation module in this embodiment mainly includes a metal cover plate 11, a first casing 12, a thermoelectric cooler 13 (Thermal electric cooler), a heat dissipation fin 21, a second shell 22, a first A fan 23 and a second fan 24 are formed.

[0019] In order to allow most of the heat source produced by the central microprocessor 3 to conduct to the thermoelectric cooler 13, the metal cover 11 covers the central microprocessor 3 and is in contact with the central microprocessor 3 and the thermoelectric cooler 13. The metal cover plate 11 has the function of concentrating the heat generated by the central microprocessor 3. The first housing 12 is composed of inner and outer two-layer shell walls 121...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com