High-performance mechanical particle spreader

A high-performance mechanical, particle technology, applied in aircraft indicating devices, aircraft parts, transportation and packaging, etc., can solve problems such as the influence of current changes and stability, and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing example:

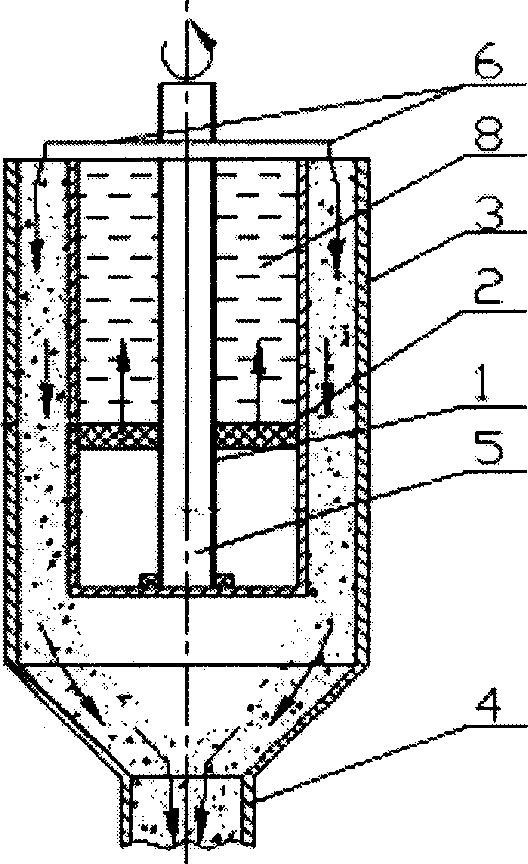

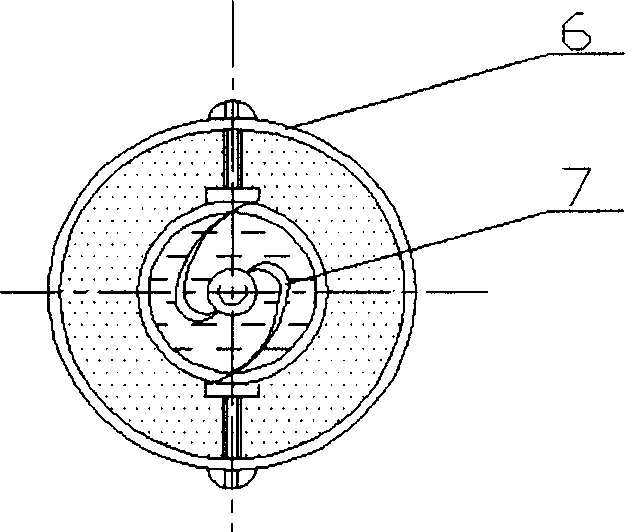

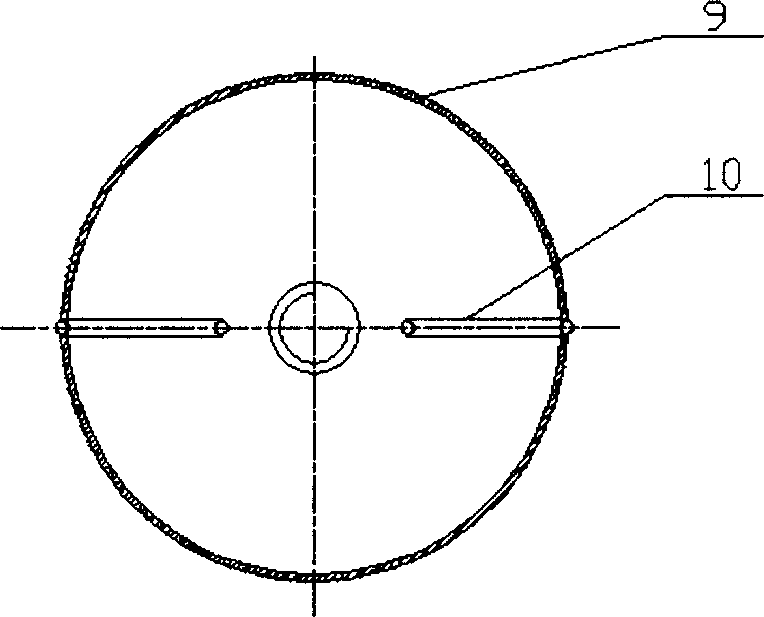

[0020] combine figure 1 , the composition of the high-performance mechanical particle broadcasting device includes a cylindrical silo 1, a container 3 is arranged outside the cylindrical silo, a screw 5 is arranged in the middle of the cylindrical silo, and the bottom of the screw passes through the bearing and the cylinder The bottom surface of the shaped silo is connected, the screw is provided with a base 2 through threads, and a screw discharge device is installed at the outlet of the cylindrical silo of the screw. combine image 3 , A rubber ring 9 is set between the base and the cylindrical silo; a guide wire 10 is set between the base and the cylindrical silo. combine figure 2 , the screw discharge device is a blade 6 installed on the screw rod.

[0021] (1) The bottom of the screw rod 5 is connected to the bottom of the cylindrical silo 1 through a bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com