Cleanable high efficiency filter media structure and applications for use

A filter medium, high-efficiency technology, applied in filtration separation, dispersed particle filtration, climate sustainability, etc., can solve problems such as poor filter purification capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0256] Set the basis weight to 59lb-3000ft -2 , a glass fiber filter media with a thickness of 0.013 inches combined with two layers of spunbond polyester base cloth material. Press a layer of scrim onto either side of the fiberglass filter media sheet. The polyester base fabric has a thickness of 0.007 inches and a basis weight of 0.5 oz-yd -2 . The three-layer substrate was flown at 10.5ft-min -1 Airflow resistance at airflow velocity is 39 mm water. The substrate is at 10.5ft-min -1 Efficiency (DOP) at air velocity was 99.97%. The substrate material is then combined with the electrospun nanofiber layer. The polyamide nanofibrous layer has an efficiency of 40% and a basis weight of approximately 0.1 gm-m when measured according to ASTM 1215 -2 .

example 2

[0258]Repeat Example 1 except that the nanofibrous layer has an efficiency of 70% and a basis weight of approximately 0.2 gm-m when measured according to ASTM 1215 -2 .

example 3

[0260] Repeat Example 1 except that the nanofibrous layer has an efficiency of 95% and a basis weight of approximately 0.3 gm-m when measured according to ASTM 1215 -2 .

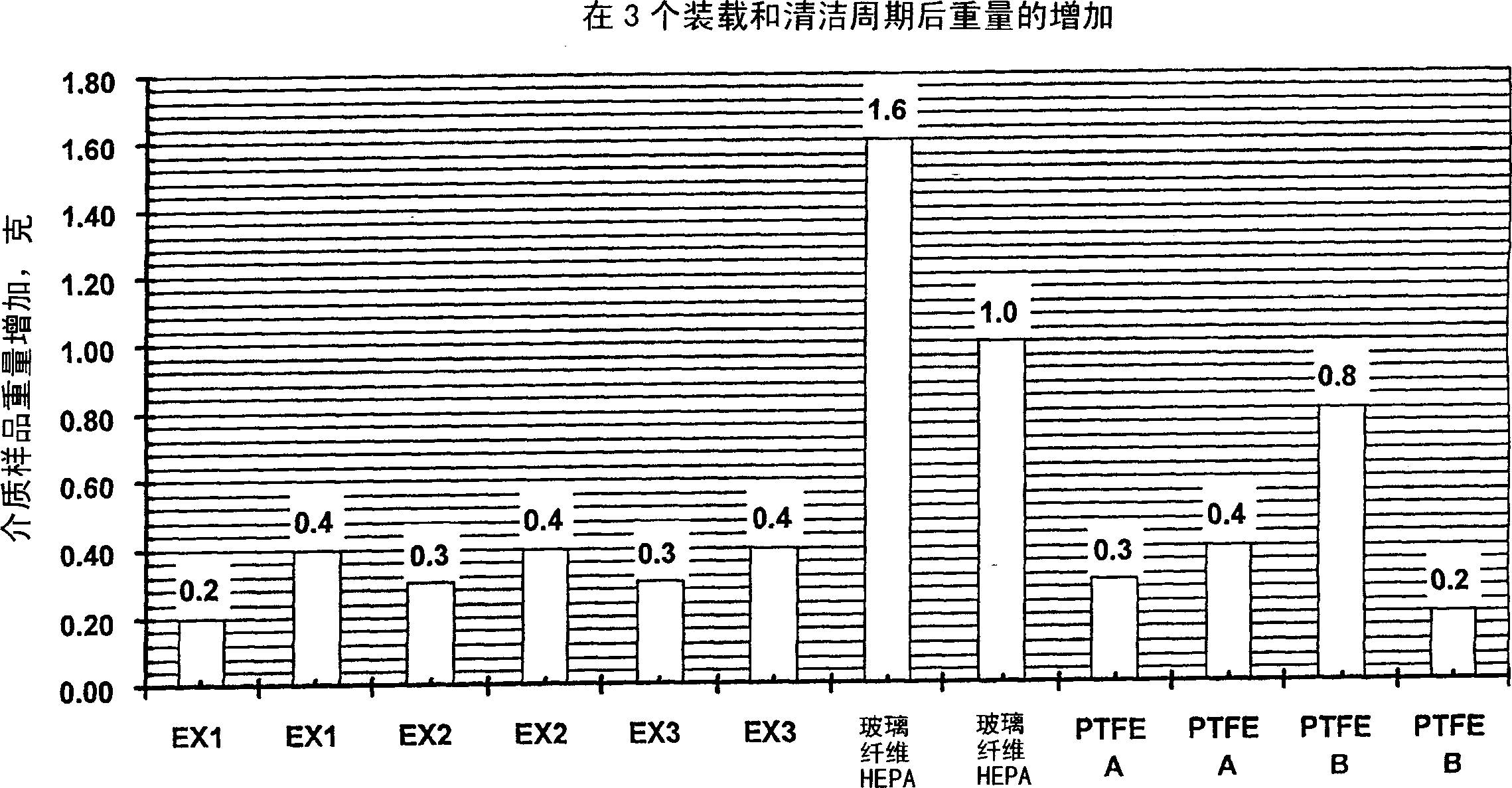

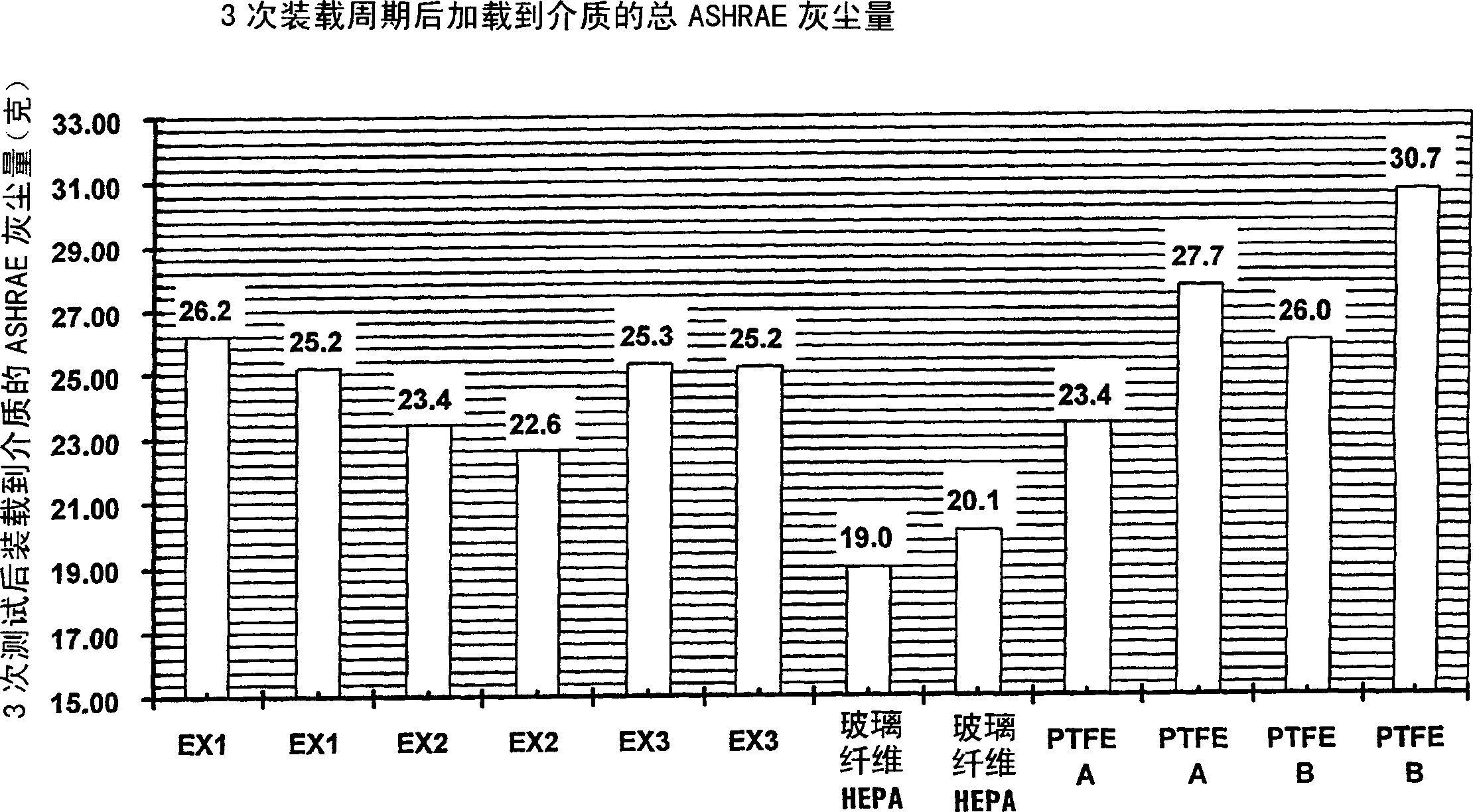

[0261] The media disclosed in Examples 1-3 were tested in a flat plate configuration in which its filtration characteristics were examined, including its pressure drop, dust and dirt loading capacity, and purification characteristics. The parameters are measured by first weighing a sample of flat media, placing the sample of flat media into a conduit, wherein the media is exposed to an air stream at a velocity of 10 ft-min, and an air stream at a velocity of approximately 1.03 gm-min. ASHRAE dust load. Let the apparatus run until the pressure drop across the media is 30 inches of water. The media was then removed from the conduit and weighed to record the dust load. The media was then clamped to the frame, and the frame set was turned over on the bin. Some of the dust falls off right away, lightly tap th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com