Master cylinder

A technology for cylinder body and inner diameter, which is applied in brakes, mechanical equipment, transportation and packaging, etc. It can solve the problems of increased processing cost and time spent in processing, and achieve the effects of shortening processing length, suppressing cost increase, and reducing air retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

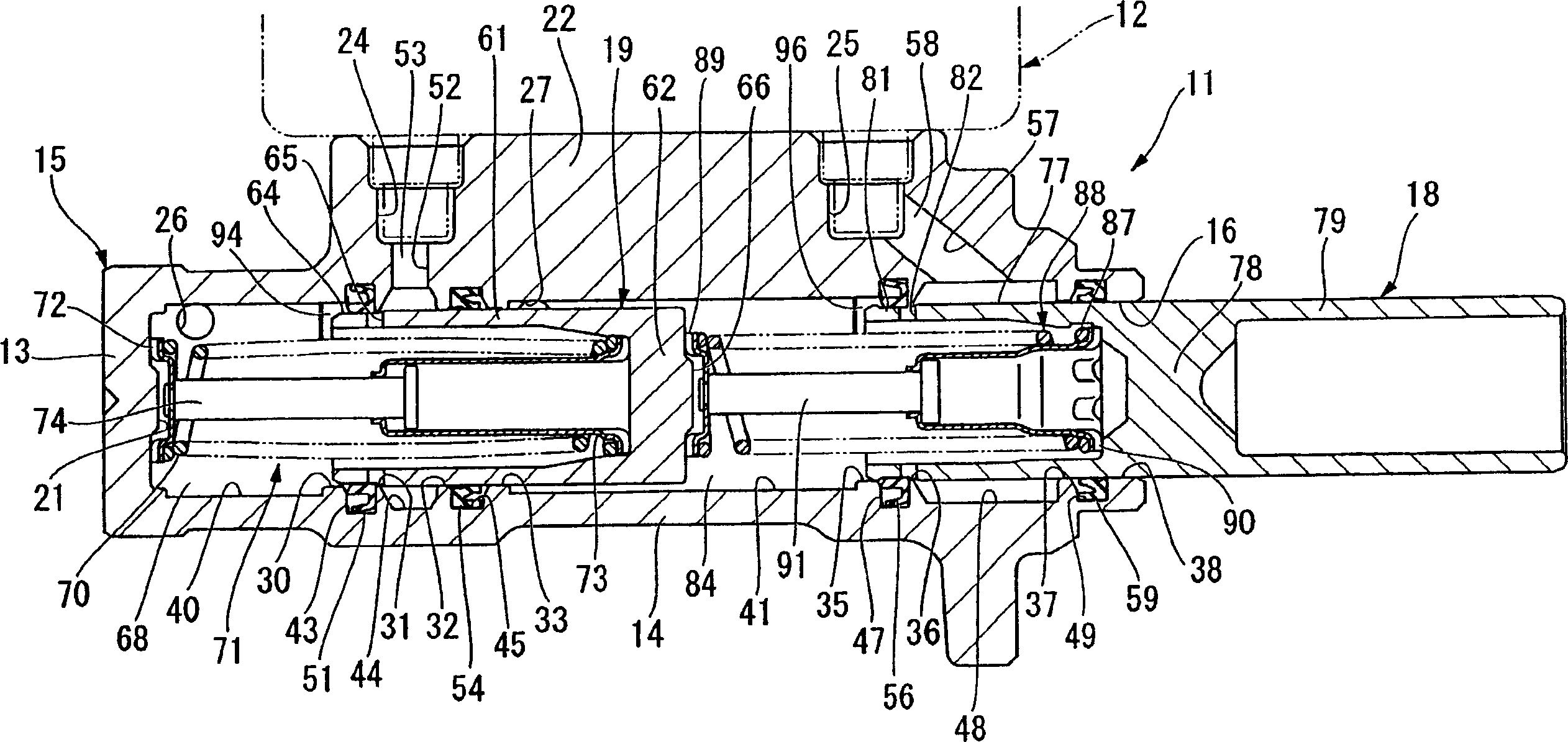

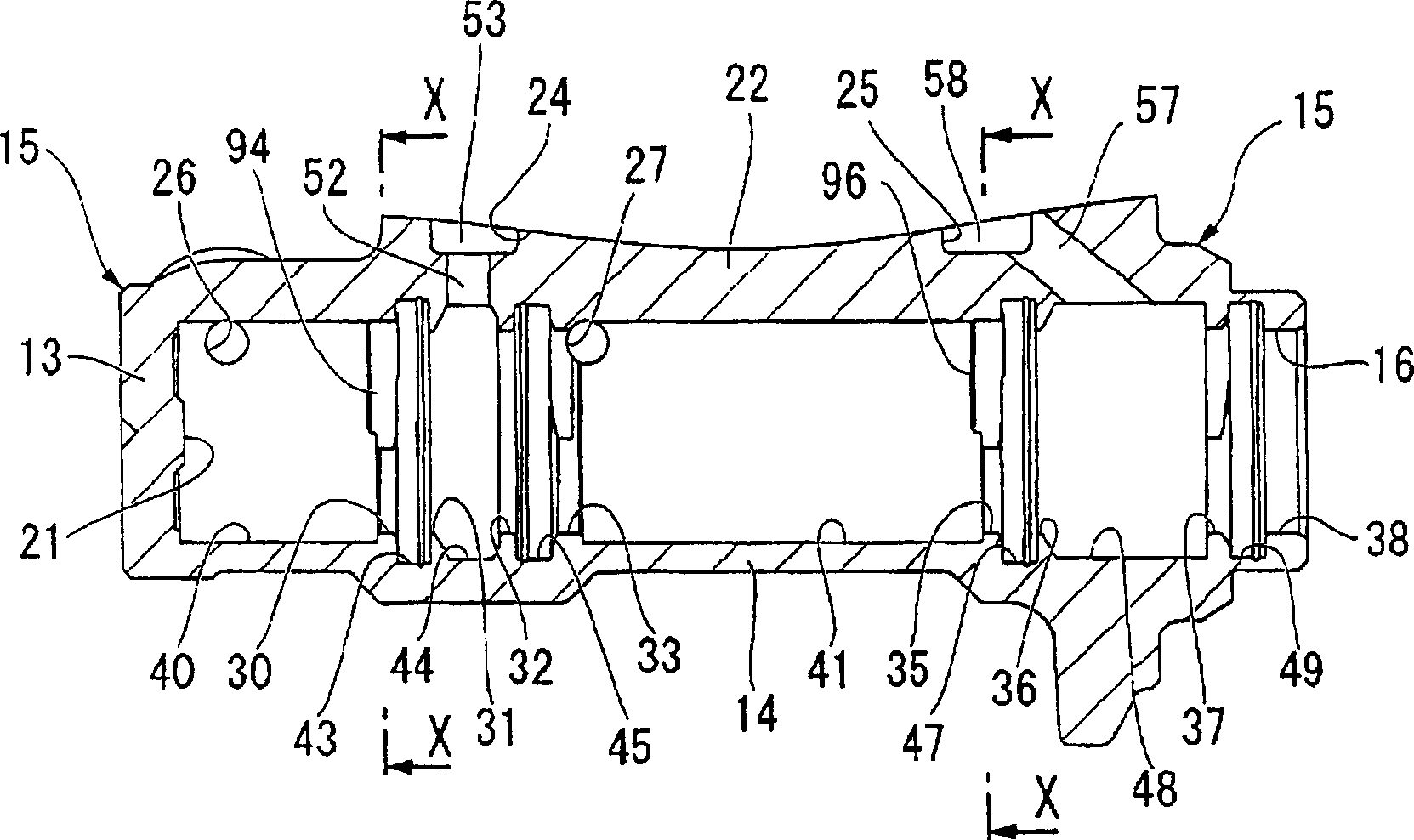

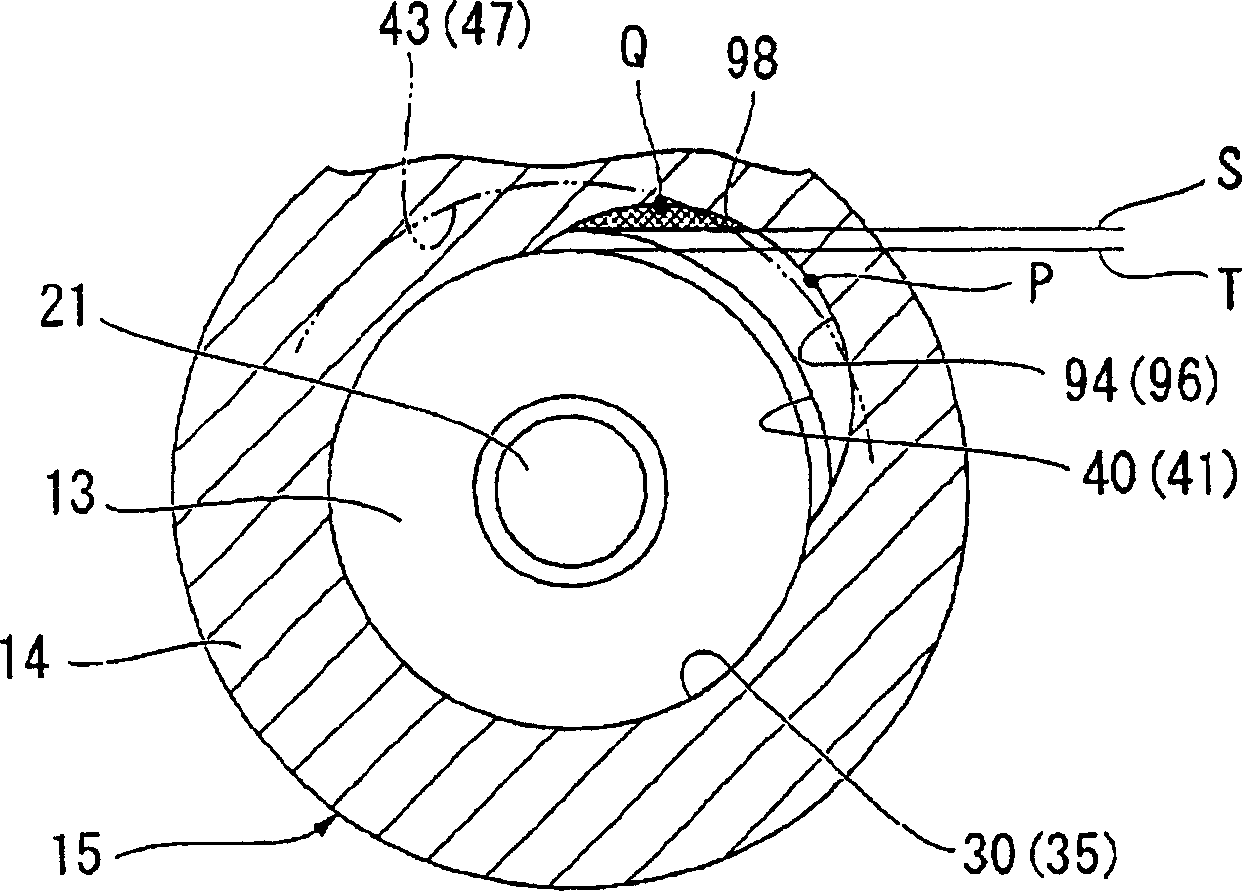

[0047] Refer to attached Figure 1~5 A master cylinder according to an embodiment of the present invention will be described.

[0048] figure 1 In the figure, reference numeral 11 denotes a master cylinder in this embodiment, which generates brake fluid pressure by a force corresponding to the operation amount of the brake pedal introduced through a brake booster not shown. An oil tank 12 for supplying and discharging brake fluid to the upper side of the master cylinder 11 is attached.

[0049] The master cylinder 11 is a tandem type cylinder having: a cylinder main body 15 having a bottom 13 and a cylindrical portion 14, processed into a bottomed cylindrical shape from one material, and disposed on the vehicle in a transverse posture; a primary piston (piston ) 18, which is slidably inserted into the opening 16 side of the cylinder main body 15 along the axis of the cylindrical portion 14 of the cylinder main body 15 (hereinafter referred to as the cylinder shaft) ( figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com