Scaling method of laser gas analysis system

An analysis system, laser gas technology, applied in the calibration field of laser gas analysis system, can solve the problems of unreliable test results, unstable performance, difficult sample processing, etc., and achieve the effect of easy acquisition, low cost, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

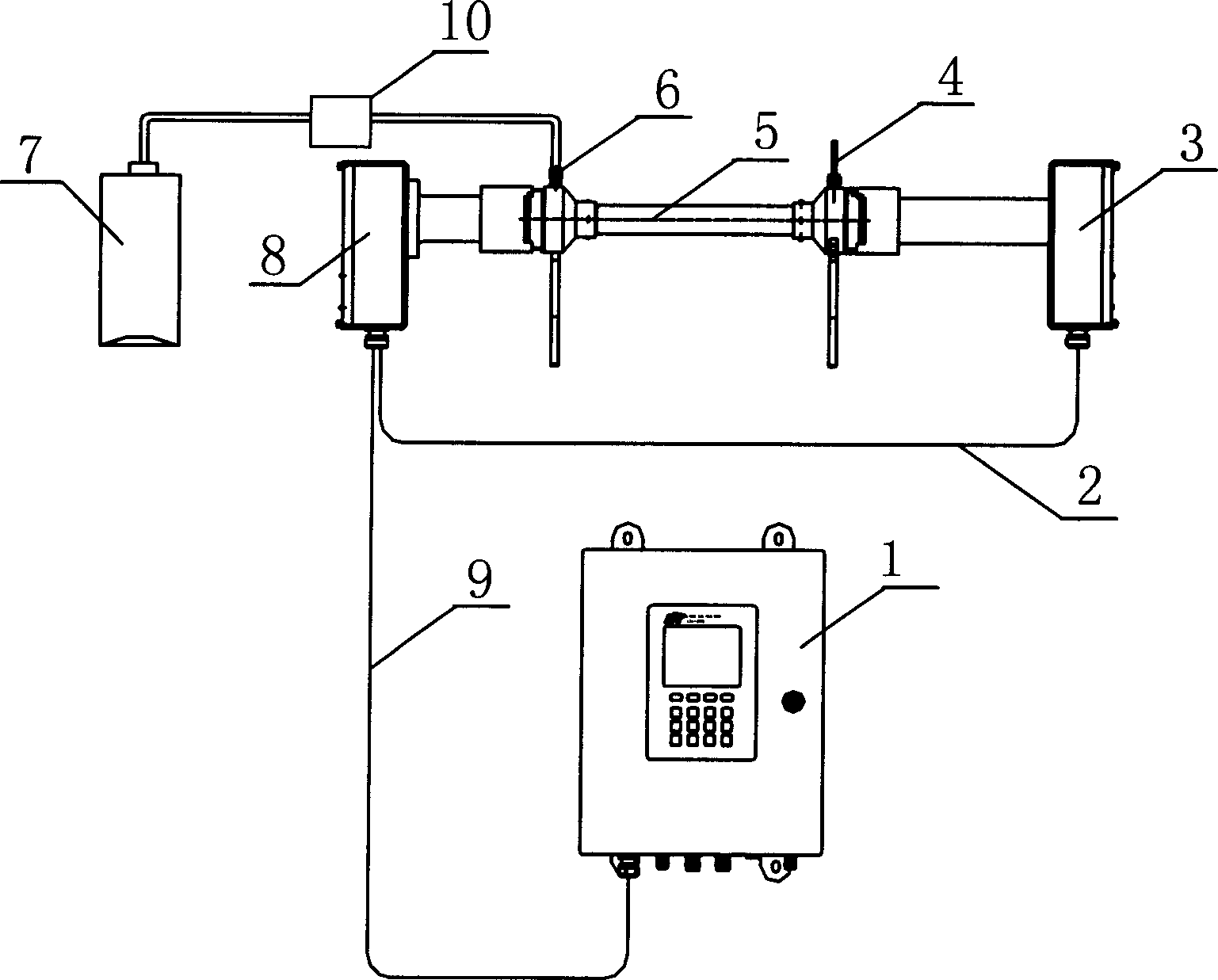

[0037] figure 1 It is a schematic diagram of the calibration device structure of a laser gas analysis system. The laser light emitted by the light emitting unit 8 passes through the gas sample in the calibration gas chamber 5 and is received by the light receiving unit 3. The received signal is transferred at the light emitting unit 8 through the cable 2, and then sent to the signal analysis unit 1 through the cable 9. The gas source 7 is connected to the gas inlet 6 of the calibration gas chamber 5 through the valve 10, and the gas sample is discharged from the gas outlet 4.

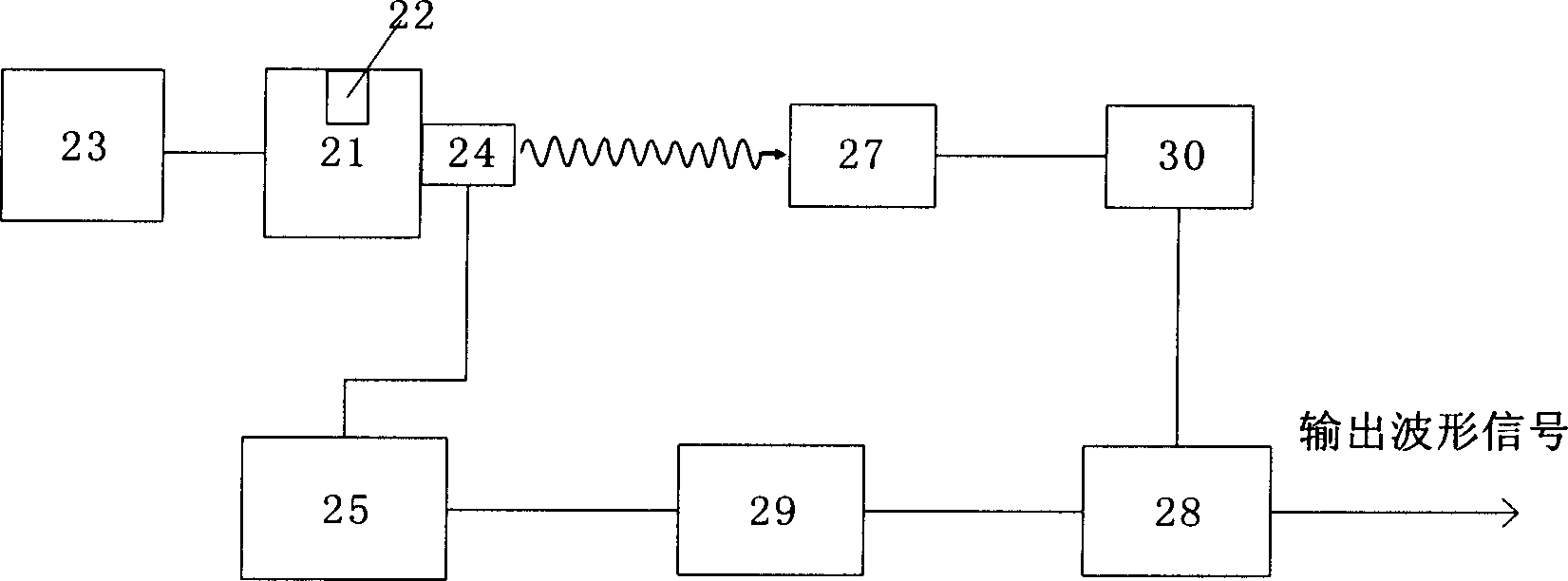

[0038] figure 2 It is a schematic diagram of a laser gas analysis system. A proportional-integral-derivative (PID) temperature control system composed of a semiconductor refrigerator (TEC) 21, a thermistor 22 and a drive circuit 23 accurately controls the temperature of the semiconductor laser 24 to a set value. The current source 25 outputs current (composed of a low-frequency triangular wave current an...

Embodiment 2

[0063] Refer to figure 1 , figure 2 This embodiment relates to a laser gas analysis system for measuring the concentration of hydrogen sulfide gas in nitrogen (range 0-200ppm). The analysis system uses a center wave number of 6290.25 cm -1 The characteristic absorption spectrum line 31 of hydrogen sulfide is used to measure hydrogen sulfide; the temperature range and pressure range of calibration are 273K-313K and 0.8atm-1.2atm respectively. This example specifically introduces the use of low-toxicity, stable performance, and non-toxic The method of calibrating by adsorbing carbon monoxide instead of hydrogen sulfide, which is highly toxic, unstable, and highly adsorbable:

[0064] a. According to the gas spectrum data in the Molecular Spectroscopy Database (HITRAN), near the measurement spectrum line 31 and within the tuning range of the semiconductor laser output frequency, select the characteristic absorption spectrum line 32 of carbon monoxide, with a central wavenumber of 6...

Embodiment 3

[0073] Refer to figure 1 , figure 2 , This embodiment relates to a laser gas analysis system for measuring the concentration of water vapor in the air (range 0-200ppm), the analysis system uses a center wave number of 6963.17cm -1 The characteristic absorption spectrum line 33 of the water vapor is used to measure the water vapor concentration; the temperature range and pressure range during calibration are 273K-313K and 0.8atm-1.2atm, respectively. This example specifically introduces the use of non-toxic, stable performance carbon dioxide instead The method of calibrating water vapor that is easy to adsorb, easy to condense, and difficult to calibrate.

[0074] a. According to the gas spectrum data in the Molecular Spectroscopy Database (HITRAN), in the vicinity of the measurement spectrum line 33 and within the tuning range of the semiconductor laser output frequency, select the absorption spectrum line 34 of carbon dioxide with a central wavenumber of 6963.94 cm -1 ;

[0075]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com