Processing method for terylene ultra-fine fiber blanket

A technology of ultra-fine fibers and processing methods, which is applied in the direction of blankets, manufacturing tools, textiles and papermaking, etc. It can solve the problems that the front fluff does not meet the requirements of the three-dimensional effect of vertical clusters, the down feathers are not plump, and the hand feels weak. Anti-lodging effect, excellent suede skinny feeling, and the effect of improving warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Prepare the DTY silk raw material of commercially available 100D / 144F; The raw material of this same specification is carried out network again, specifically the DTY silk of three 100D / 144F adopts the customary twisting machine of chemical fiber texturing industry in the prior art twisted into figure 2 The renetted yarn of 300D / 432F is shown, and the number of renetted network points 1 is controlled to be 145 / m, so as to obtain ultrafine denier yarn with high F number; Warping; then weaving with the conventional process with the warp knitting machine, the warp knitting machine is for example the GE-283 warp knitting machine that adopts the model produced by Changde Textile Machinery Factory, Changde City, Hunan Province, China, that is, through the six warp knitting machines of the GE-283 warp knitting machine Bar weaving, wherein: L1, L2, L5, and L6 produce fabrics on both sides (AB side) of the bottom layer, L3 and L4 are laid back and forth in the fabric on both sid...

Embodiment 2

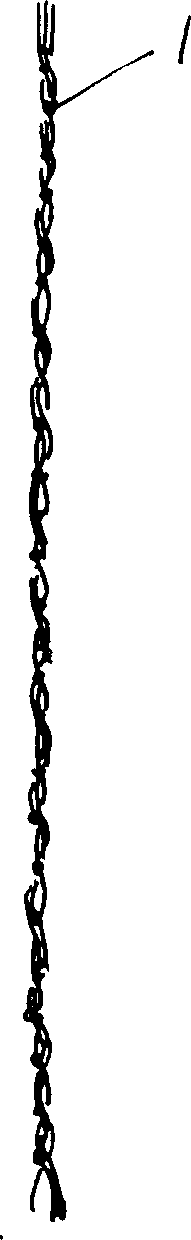

[0022] Prepare 100D / 144F and 150D / 288F DTY silk raw materials, and re-network the two different specifications of raw materials, specifically twisting three 100D / 144F and 150D / 288F DTY silk into image 3 The shown 450D / 720F re-netted yarn, and the number of controlled network points 1 is 138 / m, so as to obtain the ultra-fine denier yarn with high F number, with the same steps of embodiment 1, finally obtain the gram weight of 500 grams / m 2 , Fluffy, soft and warm polyester microfiber blanket with a pile height of 6mm.

Embodiment 3

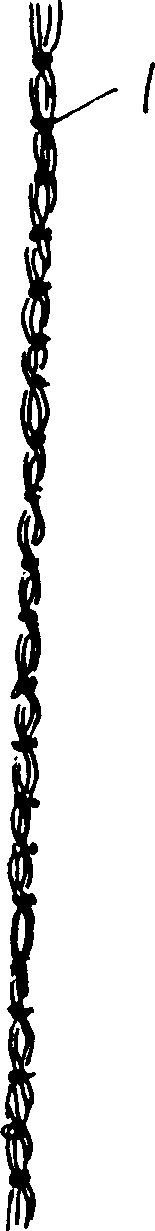

[0024] Prepare DTY silk raw materials of 75D / 144F, 100D / 144F and 150D / 288F, and re-network the raw materials of the three different specifications, specifically two 75D / 144F, one 100D / 144F and one 150D / 288F DTY filament twisted into Figure 4 Shown 400D / 720F re-network wire, and control the number of network points 1 to be 135 / m, then with the same steps of embodiment 1, finally obtain the grammage of 400 grams / m 2 , Fluffy, soft, and warm polyester microfiber blanket with a pile height of 5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com