Single crank reciprocated flying shear

A single crank, flying shear technology, applied in the direction of shearing device, shearing machine equipment, shearing machine control device, etc., can solve the problems of high manufacturing cost, complex structure and movement, easy to break down, etc., and achieve easy manufacturing and maintenance , Simple structure, quick and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

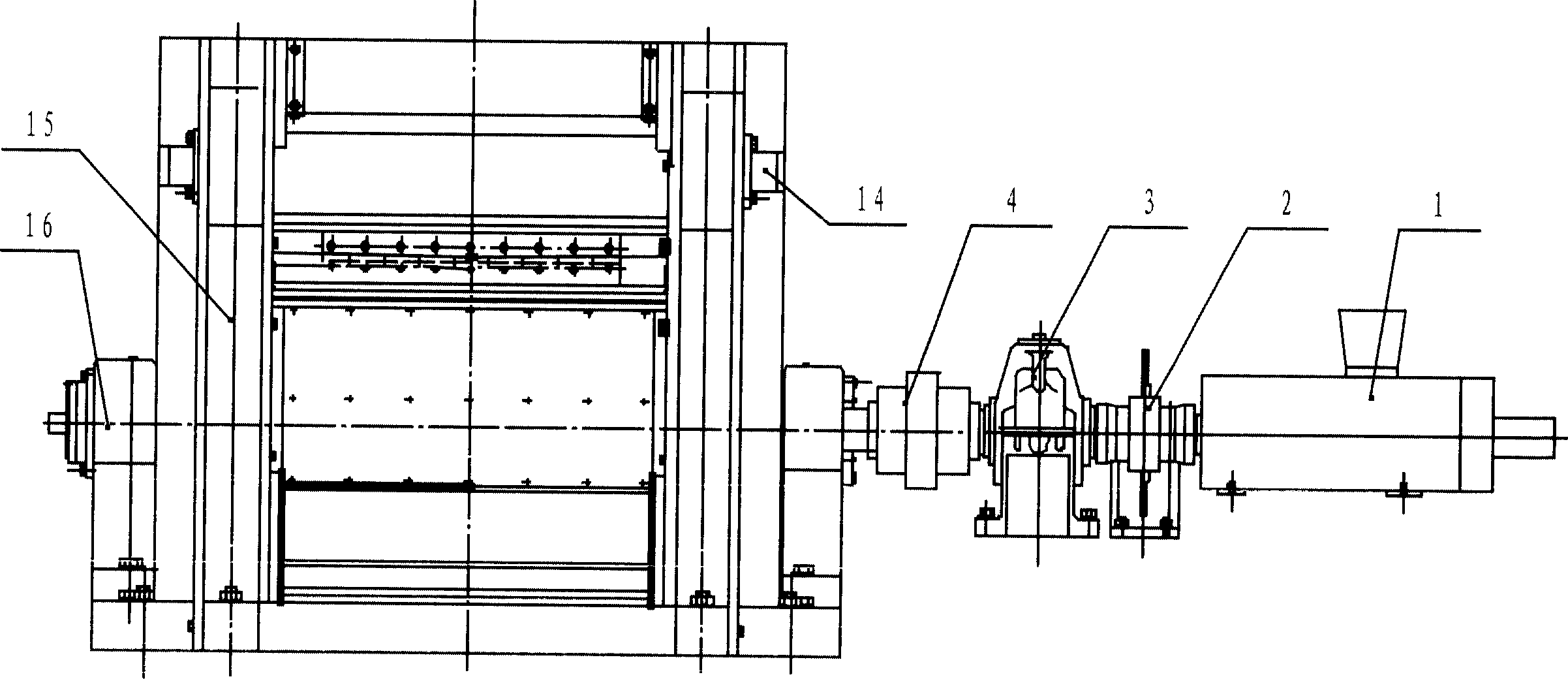

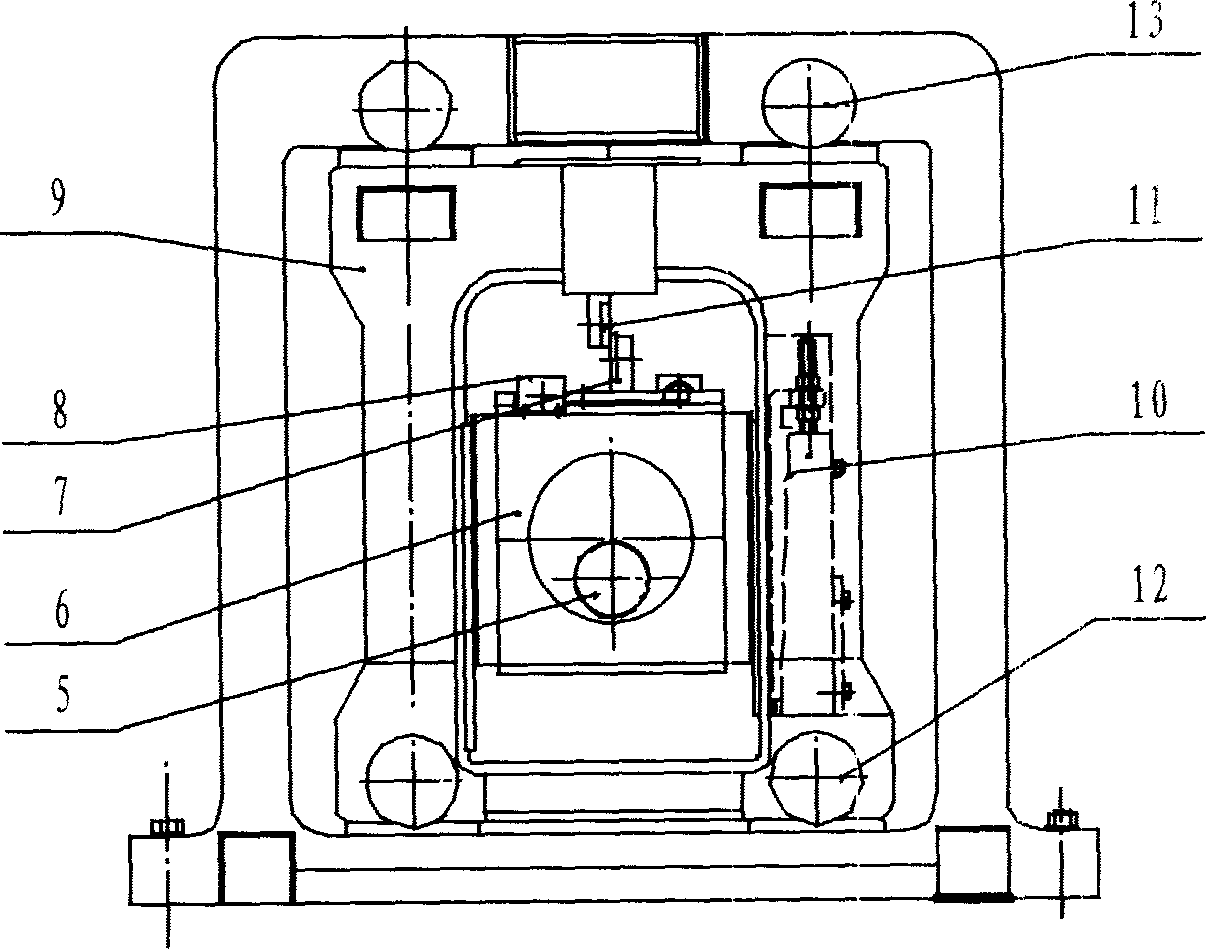

[0022] Depend on figure 1 , figure 2 It can be seen that the single crank swing flying shears of the present invention is composed of servo motor 1, braking device 2, gear box 3, safety coupling 4, crankshaft 5, box-shaped sleeve 6, lower knife and seat 7, cutting blade Clearance wedge adjustment device 8, mobile frame 9, triple wedge adjustment device 10, upper knife and seat 11, running roller 12, reaction roller 13, side guide roller 14, fixed frame 15, crankshaft bearing seat 16 , and other components.

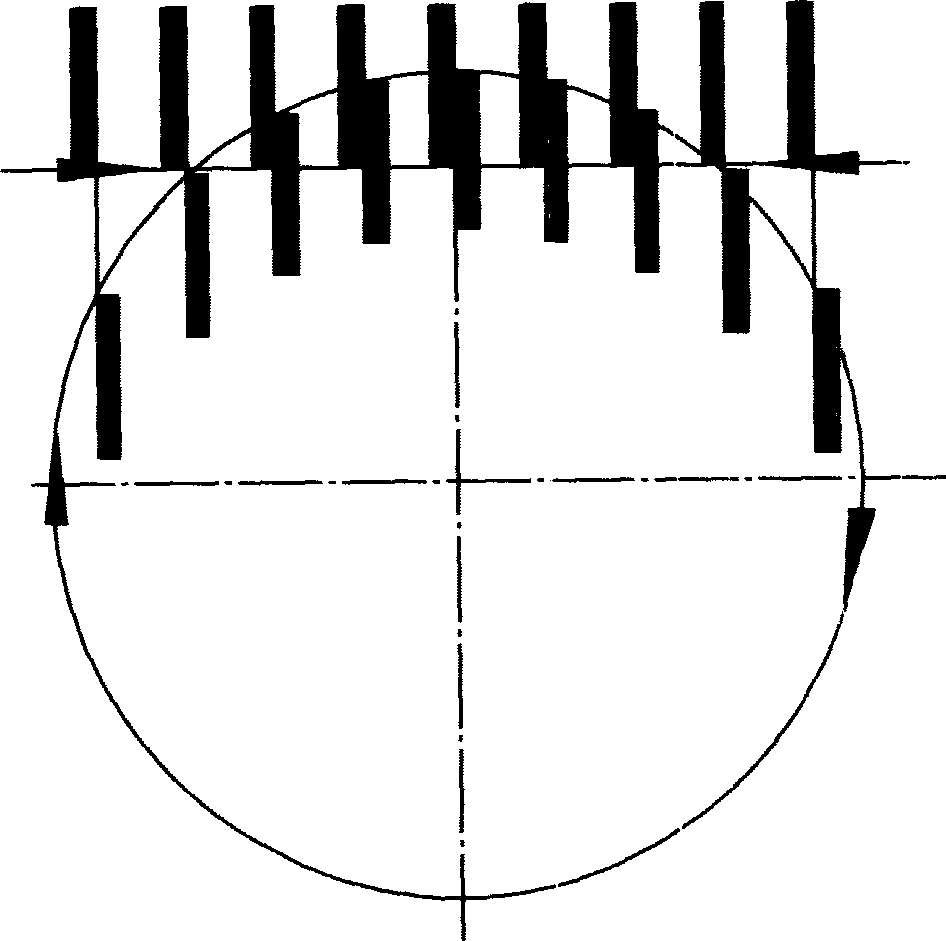

[0023] Depend on image 3 It can be seen that the single crank swing flying shear of the present invention is to drive the rotation of the single crank shaft by the transmission of the servo motor, thereby driving the relative motion of the relevant components (parts such as the box-shaped sleeve and the mobile frame) to form two completely different The running track of the upper and lower blades, that is, the running track of the lower blade is a circular motion, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com