Side sticker adhesion device for paper diaper production line

A bonding device and production line technology, applied in medical science, bandages, etc., can solve the problems of product stretching deformation, waist stick wrinkling, skewing, etc., and achieve the effect of overcoming forced stretching and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

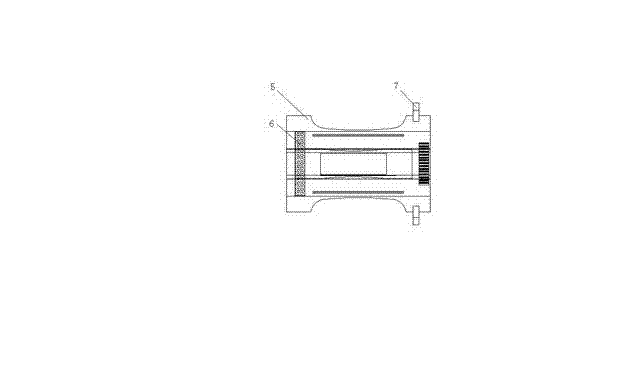

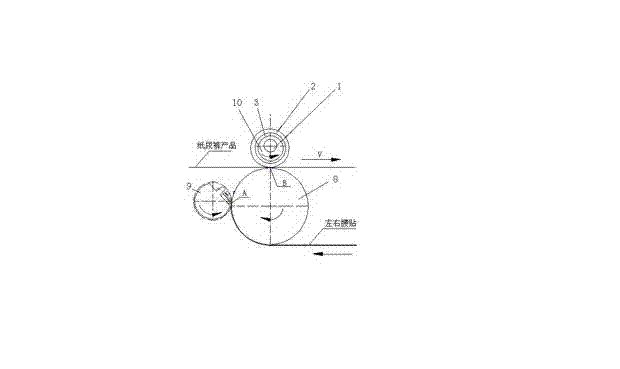

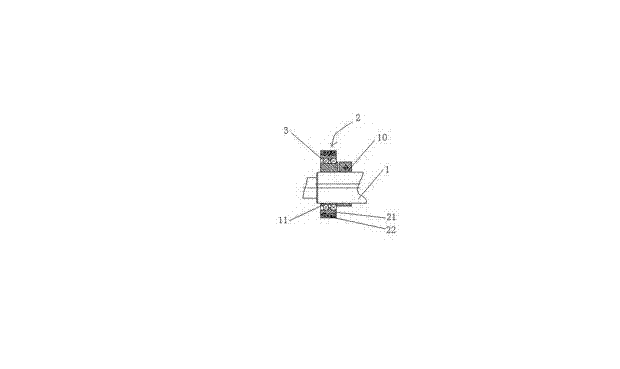

[0018] Such as figure 2 , 3 As shown, a left and right waist sticker bonding device on a diaper production line includes a press-fitting and adhesion-promoting roller shaft 1, an eccentric sleeve 10 is fixedly connected to the pressing-bonding aiding roller shaft 1, and the outer periphery of the eccentric sleeve 10 moves through a bearing 3 A ring sleeve 2 is connected. The bearing 3 is limited by a limit step and a limit clip 11 provided on the eccentric sleeve 10 .

[0019] The inner ring 21 of the ring sleeve 2 is made of steel material, and the outer ring 22 is made of silica gel material. The connection method between the inner ring 21 and the outer ring 22 is: the silicone material is melted and poured onto the outer surface of the inner ring 21 to make it.

[0020] Such as image 3 As shown, in this embodiment, the eccentric sleeve 10 is tightly hugged to the pressing and adhesion-promoting roller shaft 1, and a locking bolt is provided (to facilitate adjustment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com