Three-roller printing and driving device of gravure printing machine

A technology of a gravure printing machine and a driving device, which is applied in the directions of a gravure rotary printing machine, a printing machine, a rotary printing machine, etc., and can solve problems such as defects in printed products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is a further description of the three-roller printing and driving device of the invention of a gravure printing machine in conjunction with the accompanying drawings and specific embodiments:

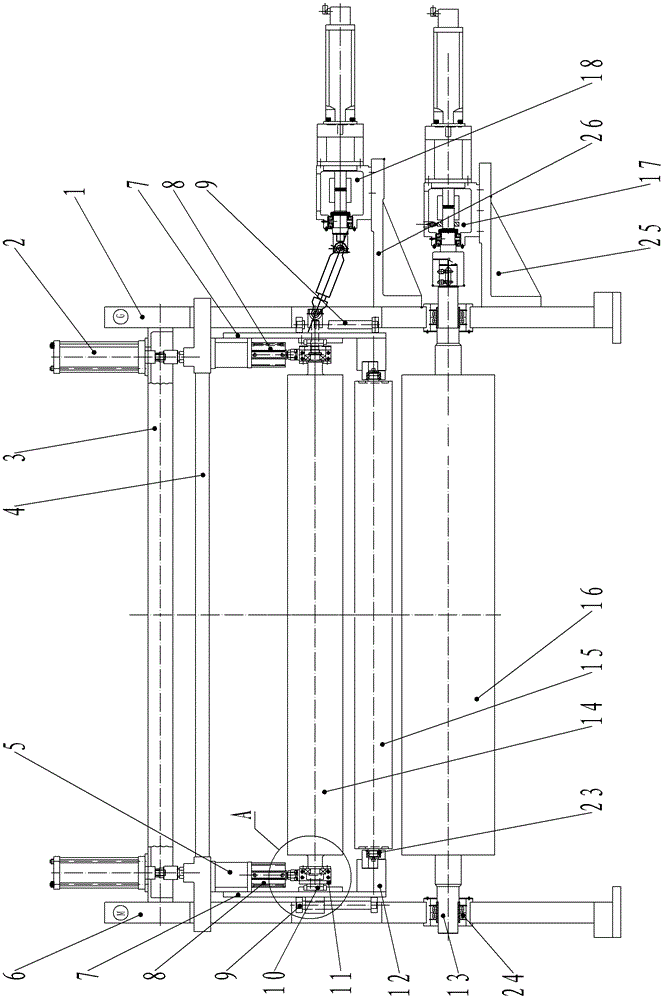

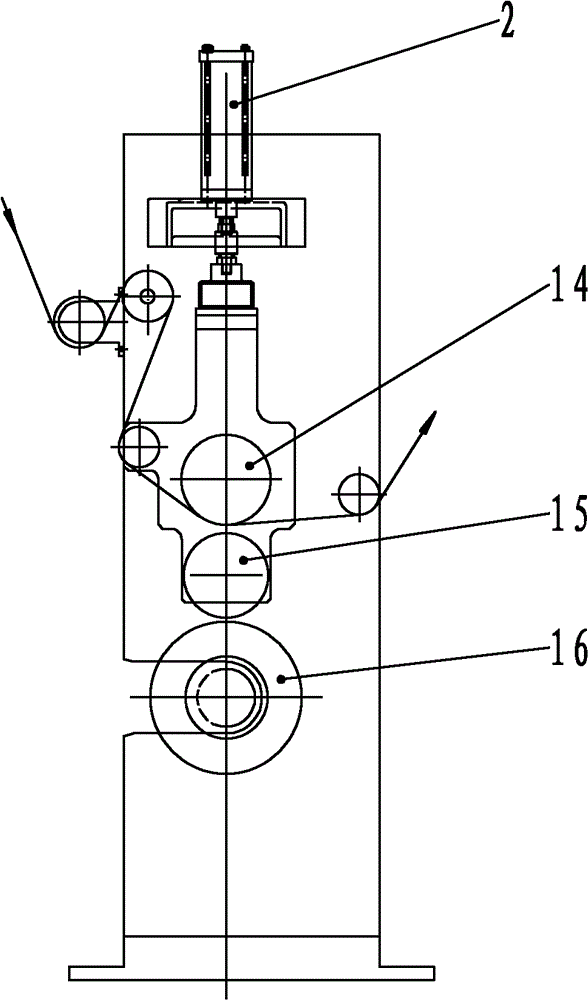

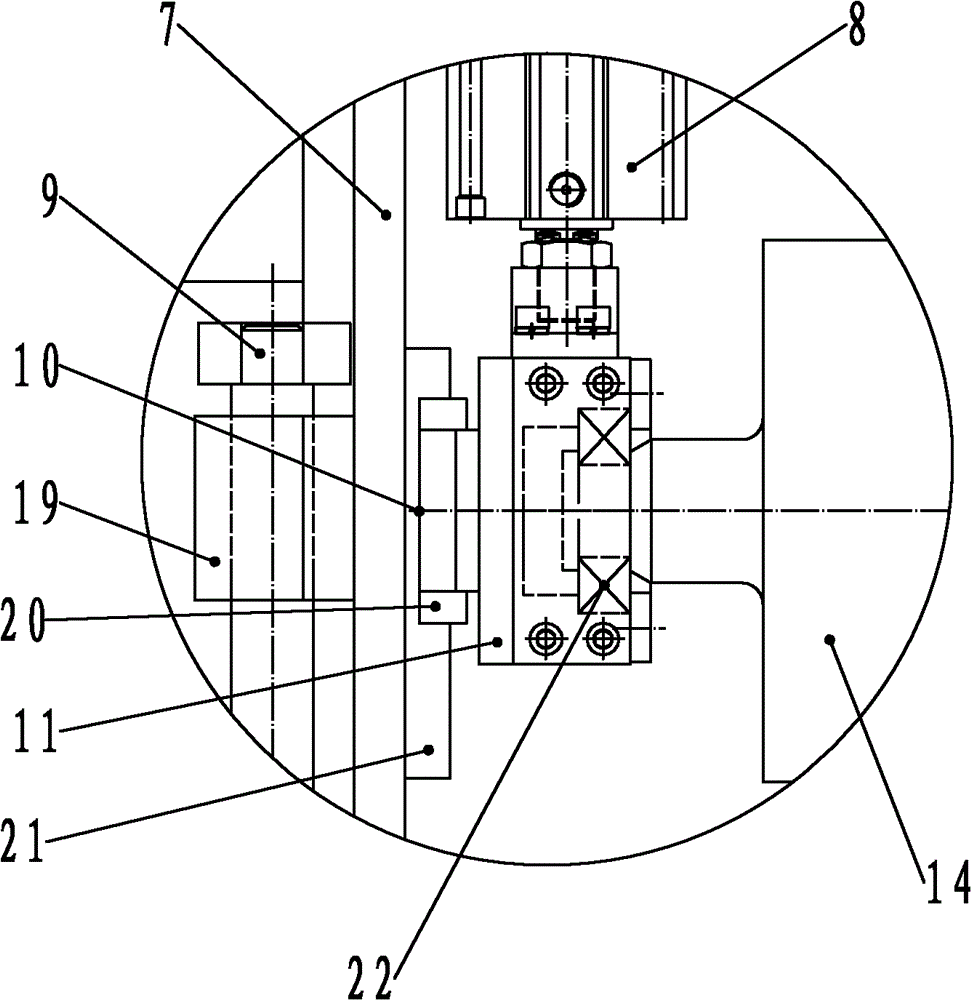

[0016] figure 1 It is a structural schematic diagram of the three-roller printing and driving device of the gravure printing machine of the present invention. In the figure, the two ends of the version roller 16 are fixed on the wallboards 1 and 6 on both sides through bearings 24, and are fixed on the inner sides of the wallboards on both sides. There is a guide shaft 9 in the vertical direction, a slide seat 19 is arranged on the guide shaft 9, a supporting plate 7 is fixed on the sliding seat 19, and a rubber roller base 12 is fixed at the lower end of the supporting plate 7, and the two ends of the rubber roller 15 pass through The bearing 23 is fixed on the rubber roller base 12; the linear guide rail pair 10 is fixed in the middle of the supporting plate 7, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com