Automatic paint packaging device

A technology of packaging device and transmission device, which is applied in the field of engineering, can solve the problems of single function and low efficiency, and achieve the effect of synchronous motion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

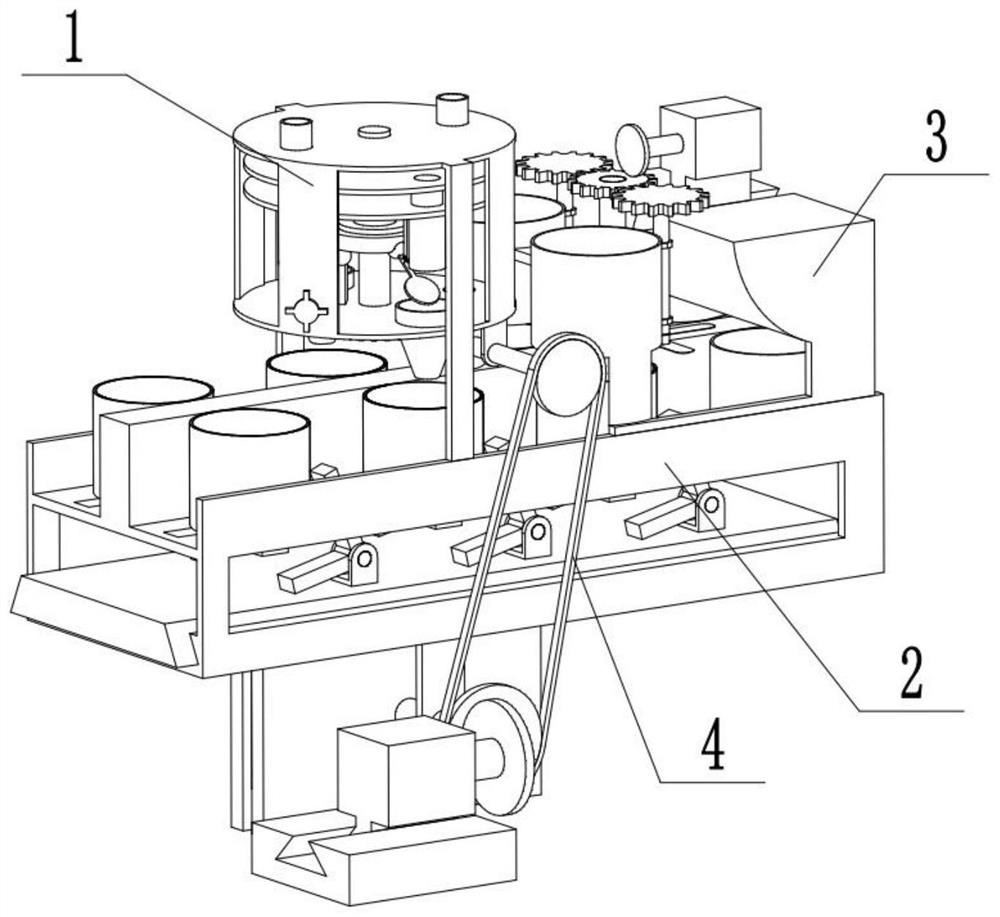

[0026] Combine below Figure 1-10 Describe this embodiment, an automatic paint packaging device, including a liquid outlet device 1, a transmission device 2, a capping device 3, and a belt 4, the liquid outlet device 1 is connected to the transmission device 2, and the transmission device 2 is connected to the capping device 3 phases are connected, the liquid outlet device 1 is connected with the belt 4, and the transmission device 2 is connected with the phase.

specific Embodiment approach 2

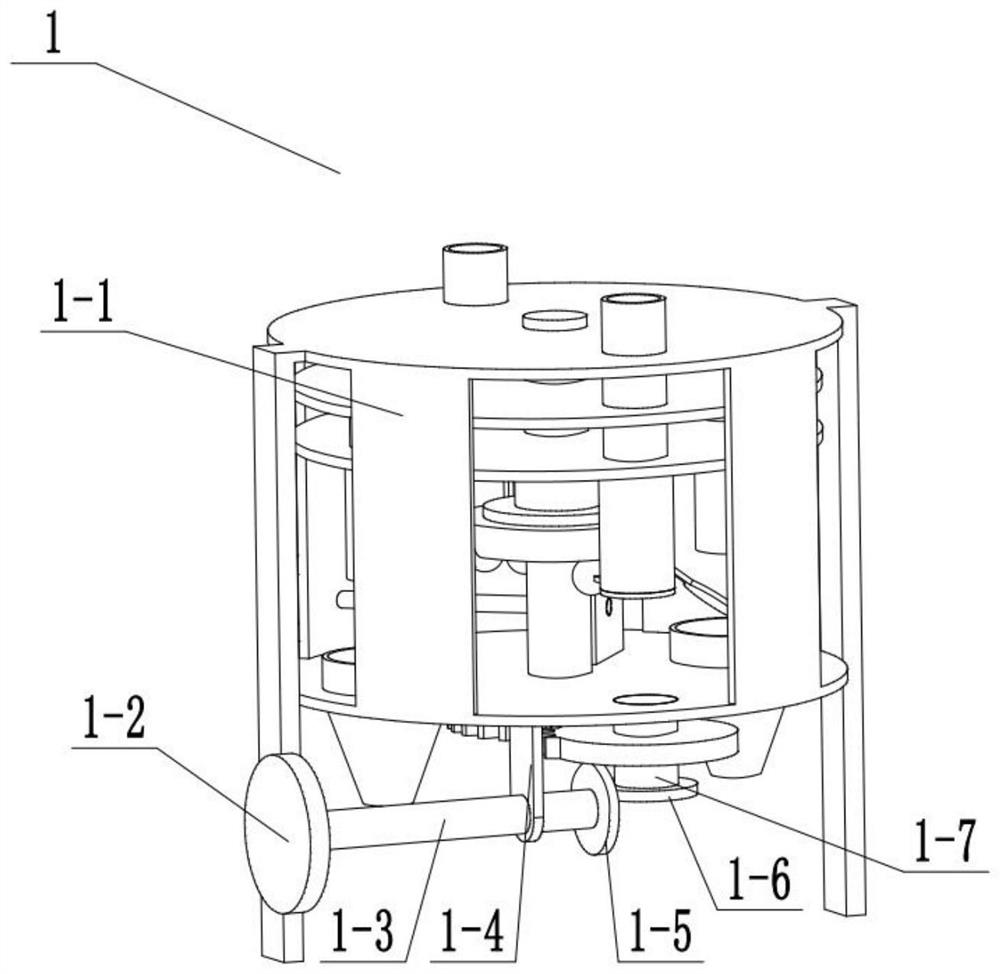

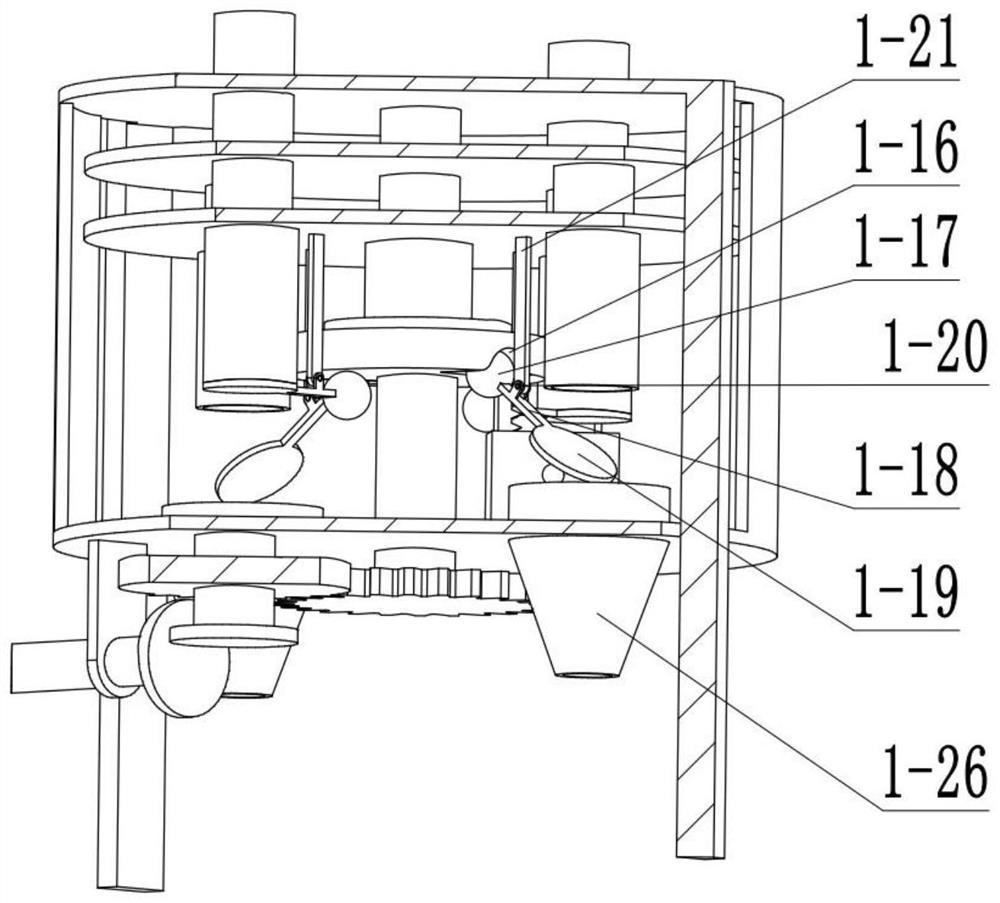

[0028] Combine below Figure 1-10Describe this embodiment, this embodiment will further explain Embodiment 1, the liquid outlet device 1 includes a housing bracket 1-1, a runner 1-2, a linkage column 1-3, a bracket 1-4, a rotary Wheel two 1-5, runner three 1-6, linkage column two 1-7, half gear one 1-8, gear one 1-9, linkage column three 1-10, disc one 1-11, container one 1 -12, disc two 1-13, container two 1-14, functional disc 1-15, round groove 1-16, small ball 1-17, connecting rod one 1-18, round cover 1-19, hinge Column one 1-20, connecting rod two 1-21, tooth column 1-22, gear two 1-23, connecting column one 1-24, turn knob 1-25, outlet pipe 1-26, inlet pipe 1- 27. The runner one 1-2 is fixedly connected with the linkage column one 1-3, the linkage column one 1-3 is rotationally connected with the bracket one 1-4, the shell bracket 1-1 is fixedly connected with the bracket one 1-4, and the linkage column one 1-3 is fixedly connected with runner 2 1-5, runner 2 1-5 is e...

specific Embodiment approach 3

[0031] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain Embodiment 1, the transmission device 2 includes a transmission bracket 2-1, a packaging box 2-2, a motor 2-3, a base boss 2-4, and a runner 4 2-5, runner five 2-6, connecting rod three 2-7, bracket two 2-8, fixed block 2-9, gear block 2-10, half gear two 2-11, function bump 2-12, Function bar 2-13, hinge column 2 1-14, slide block 1-15, transmission bracket 2-1 is slidably connected with packing box 2-2, motor 1 2-3 is slidably connected with base boss 2-4, motor 1 2-3 is fixedly connected with runner four 2-5, runner four 2-5 is connected with runner five 2-6, runner five 2-6 is fixedly connected with connecting rod three 2-7, connecting rod three 2- 7 is rotationally connected with bracket two 2-8, bracket two 2-8 is fixedly connected with transmission bracket 2-1, fixed block 2-9 is fixedly connected with transmission bracket 2-1, gear block 2-10 is connected with half gear tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com