Chip part manufacturing method and chip parts

A manufacturing method and component technology, which is applied in the manufacture of chip components and in the field of chip components, can solve problems such as chip component cracks, breakage, and inability to move and supply smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

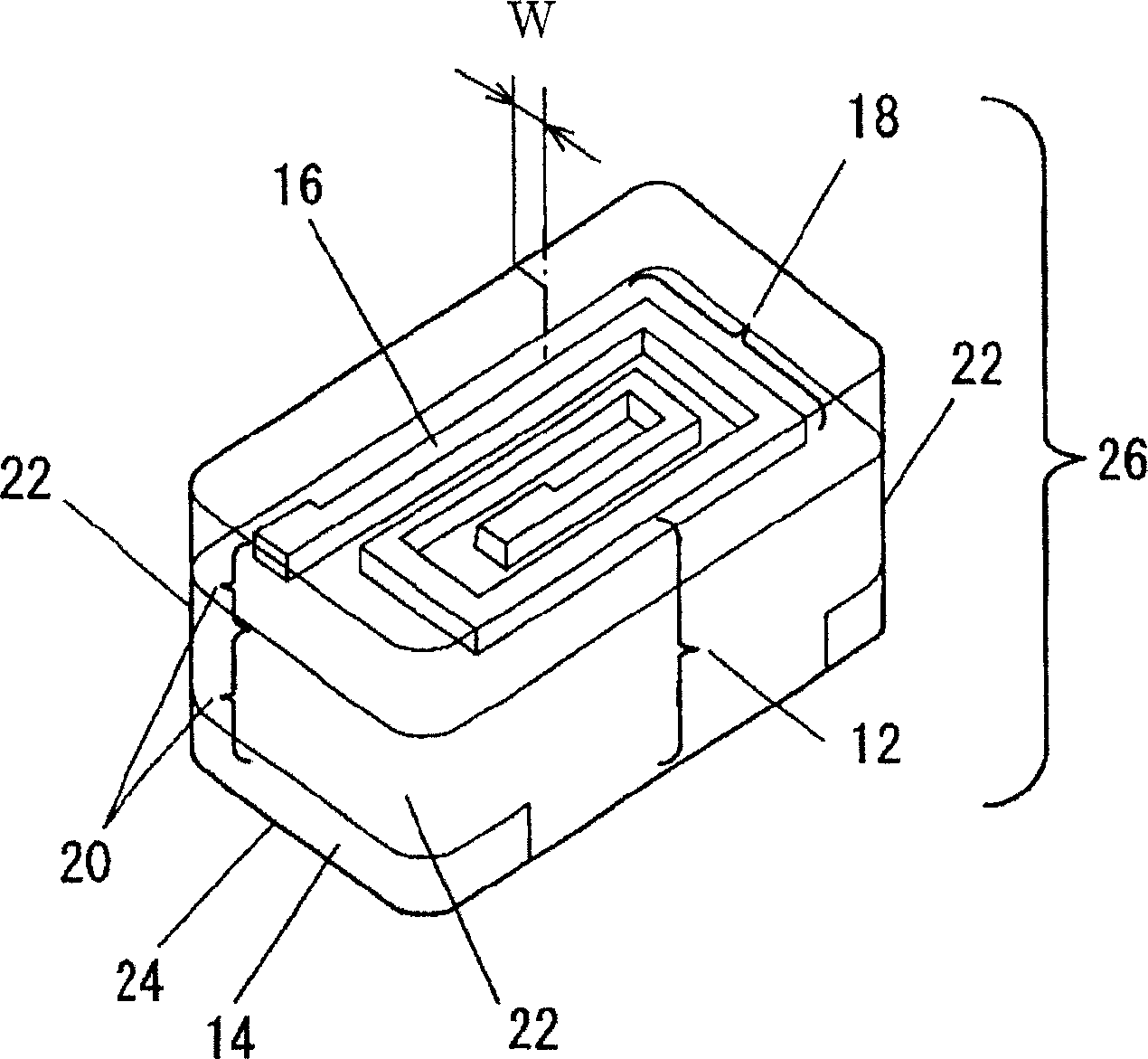

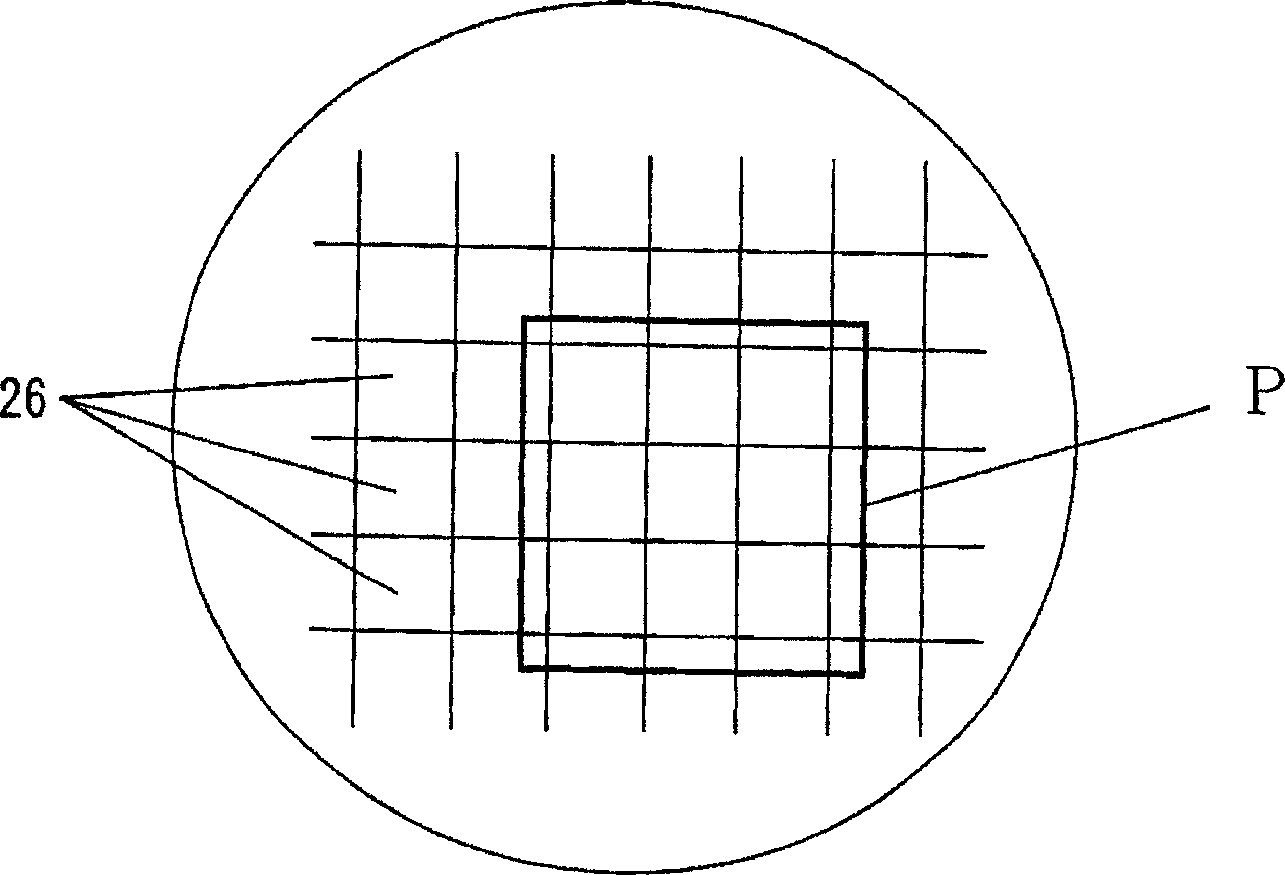

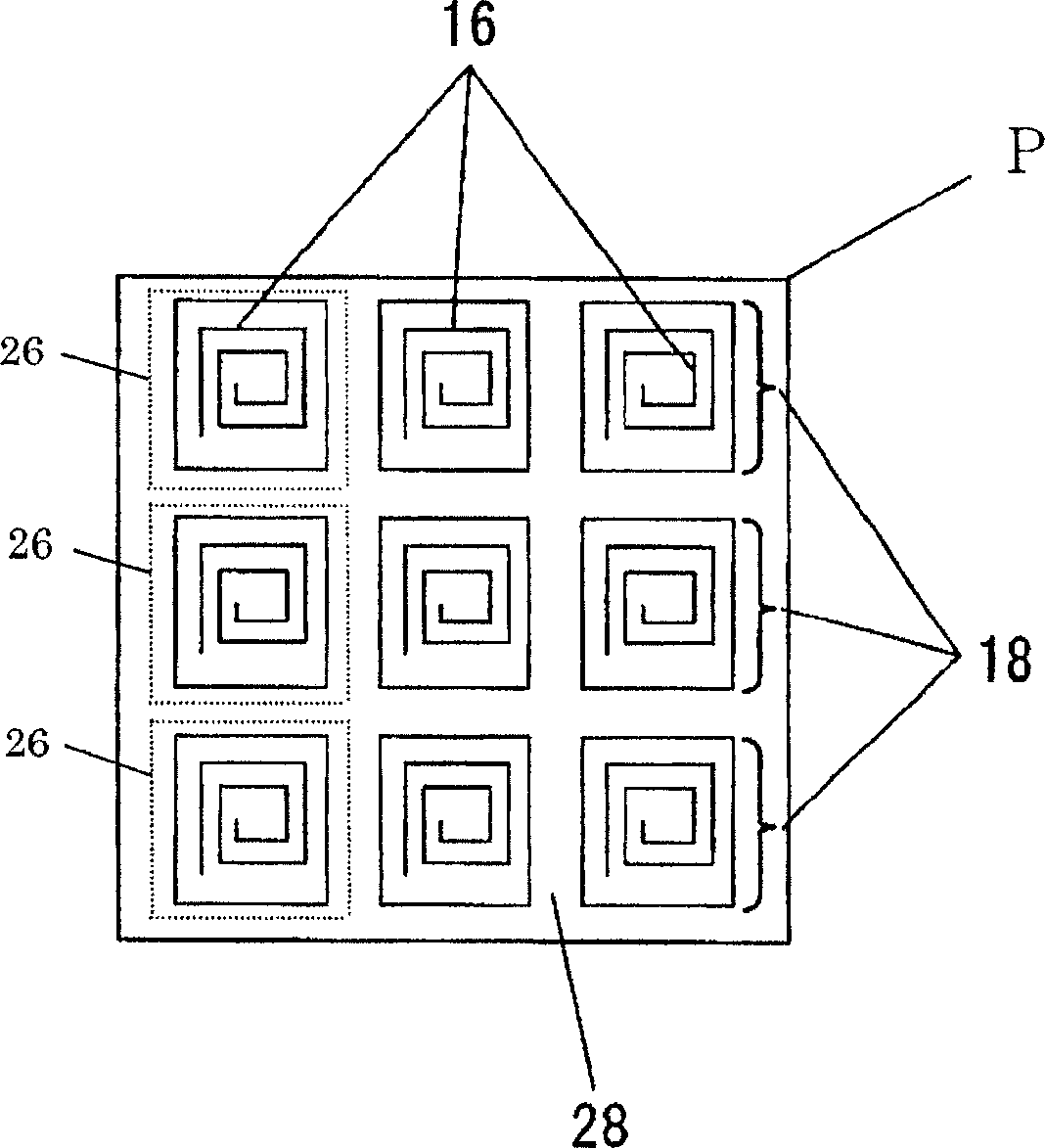

[0033] figure 1 It is a perspective oblique view of the chip part of Embodiment 1, figure 2 is a plan view showing a state in which a plurality of chip components are connected, image 3 yes figure 2 An enlarged top view of part P of . Figure 4 A~ Figure 4 F is a process diagram showing one manufacturing process of the chip component of the present invention.

[0034] exist figure 1 In , there is shown a chip component 26 according to an embodiment of the present invention, for example, a chip coil component. The chip component 26 has a substantially square transparent base 12 , electrodes 14 arranged on the lower surface of the base 12 , and a coil portion 18 formed of a spiral metal layer 16 embedded in the base 12 . The base body 12 is formed by stacking insulating resin layers 20 made of cured photosensitive resin obtained by curing the photosensitive resin.

[0035] In addition, the first corner portion 22 of the chip component 26 is formed in a substantially...

Embodiment approach 2

[0065] Figure 5 A~ Figure 5 G shows another manufacturing process of the chip component 26 of the present invention. Among them, the method used in the first embodiment can also be applied in the second embodiment figure 1 , figure 2 with image 3 , so the detailed description is omitted. Embodiment 2 shows one more manufacturing process than Embodiment 1. Moreover, it is clear at a glance Figure 5 A~ Figure 5 G and Figure 4 A~ Figure 4 F is very similar.

[0066] Figure 5 A shows an electrode forming step. exist Figure 5 In the upper part of A, a release layer (not shown) is formed on one main surface of the substrate 30, and the insulating resin layer 20 having the electrode cavity 34 is formed on the upper portion of the release layer by photolithography. In addition, the lift-off layer can be formed of, for example, a lift-off resist. If the peeling layer is formed, the chip components to be described later can be easily separated in the frame-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com