Triangle mechanism for needle selection of flat knitting machine

A technology of flat knitting machine and cam, applied in the direction of weft knitting, knitting, textile and paper making, etc., can solve the problems of high manufacturing cost, poor working reliability, occupying space, etc., and achieve high transmission reliability and motion precision, needle selection The effect of simplifying and reducing the manufacturing cost by using the triangular mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

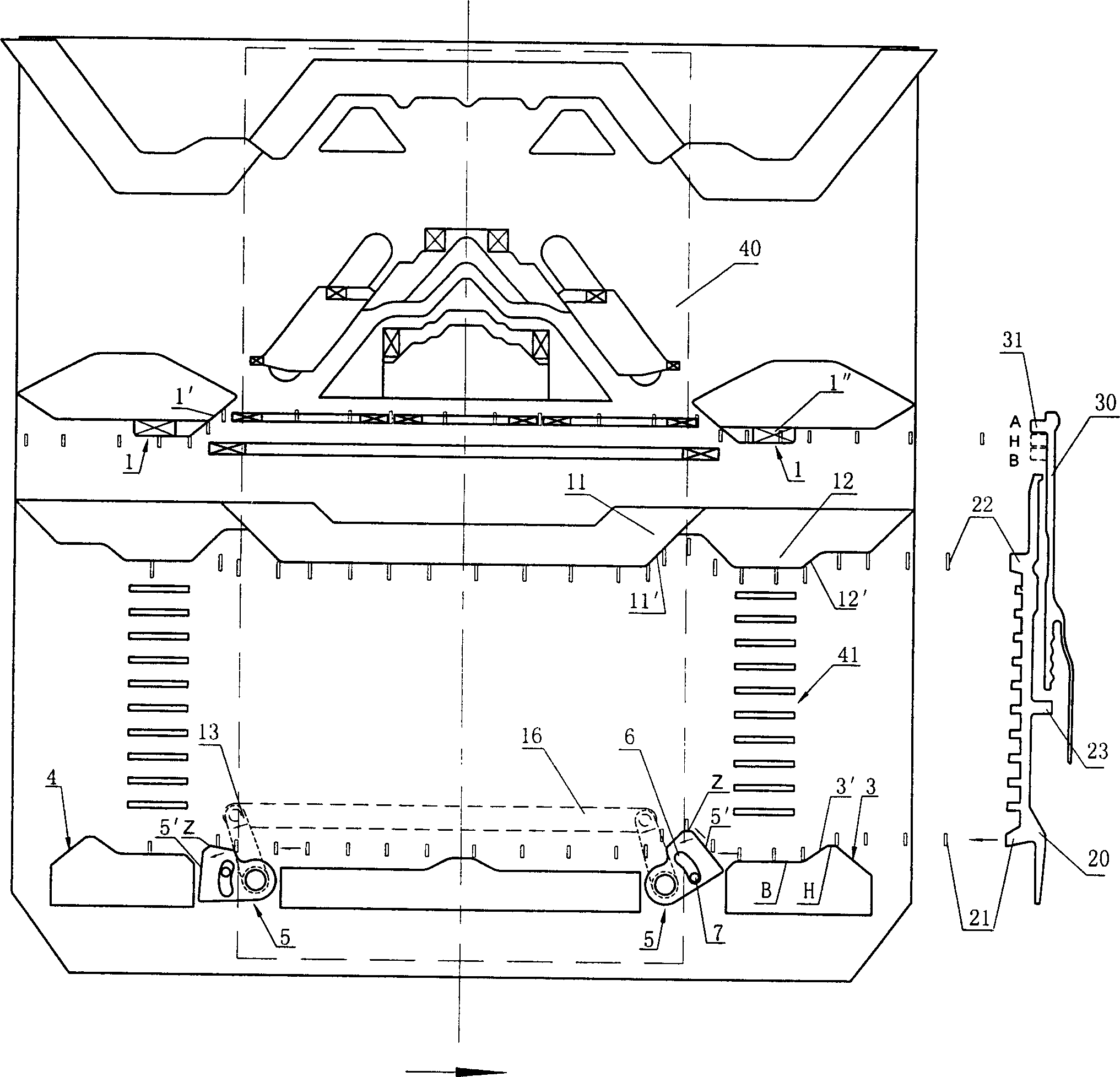

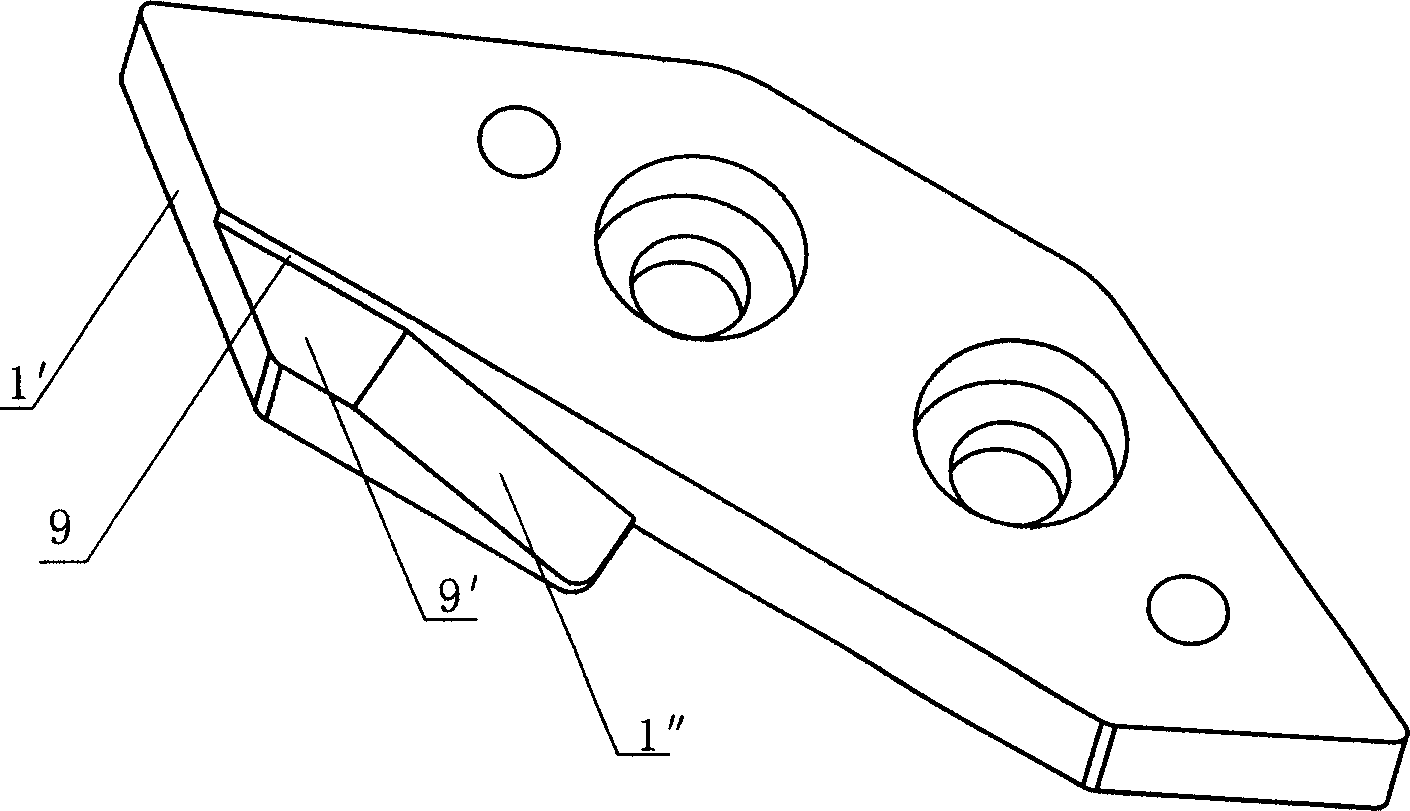

[0025] See figure 1 , the two selector movable needle cams 3 and 4 on the lower side of the knitting system are hinged to the triangular bottom plate 10 through the pivot pin 18, and the rear side of the cam bottom plate 10 corresponds to the pivot pin The position place is connected with the pendulum piece 13 of a rotating shaft altogether. The movable needle-starting triangles 5 of the two selectors are placed according to a certain positional relationship: if the needle-setting triangle 5 of the right selector is inclined, the needle-raising triangle 5 of the left selector is almost flat. The high end Z of the bevel 5' is slightly higher than the left selector jack triangle 4; and vice versa. The two selector jacks that are placed according to the above-mentioned positional relationship are respectively hinged to the two ends of a connecting rod 16 through the pendulum piece 13 that is connected with the same rotating shaft. A limit hole 6 is provided on the movable need...

Embodiment 2

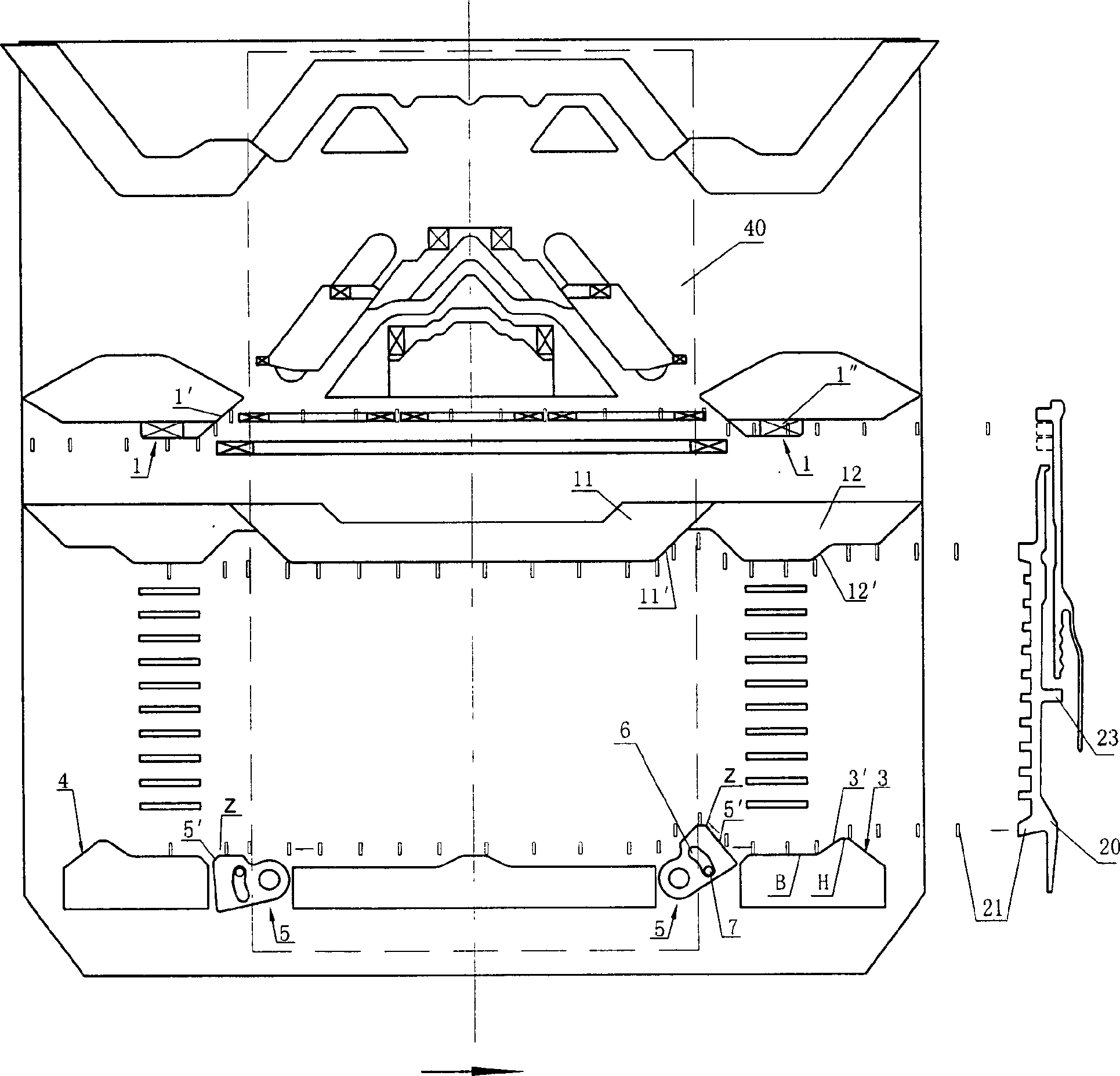

[0030] See image 3 , This embodiment is basically the same as the above-mentioned embodiment, except that a tension spring 8 is placed on the connecting rod 16 and placed in a groove of the connecting rod 16 . Like embodiment 2, the connecting rod 16 is also placed on the rear side of the triangular bottom plate, and is connected with the connecting rod 16 through the pendulum piece 13 which is connected with the movable needle raising cam 5 of the selector and placed on the rear side of the triangular bottom plate. Please refer to Figure 4 , the selector movable needle triangle 5 and the pendulum piece 13 have a total rotating shaft. A connecting pin 14 is provided on the pendulum piece 13, and a waist-shaped hole 17 is respectively provided at both ends of the connecting rod 16, and the connecting rod 16 slides with the connecting pins 14 on the two pendulum pieces through the waist-shaped hole 17. The arc length (or the included angle) of the limit hole 6 on the needle o...

Embodiment 3

[0034] See Figure 5 , The mechanism side in the present embodiment is simpler, and the function of the connecting rod 16 is replaced by the return spring-extension spring 18. One end of extension spring 18 is connected on the triangular bottom plate 10, and one end is connected with two needle selector movable needle cams 5 .

[0035] The needle movement process of the butts of the selector jack 20 and the pattern piece 30 in this embodiment is also exactly the same as that of Embodiment 1, except that the rear butt 21 on the selector jack 20 starts to move when entering the left selector jack. In the area of the needle cam 5, the movable needle cam 5 of the needle selector has a hindering effect on the rear needle butt 21, and the rear needle butt 21 acts on the movable needle cam 5 of the needle selector, so that it rotates counterclockwise to the horizontal position, There is no hindrance to the left movement of the needle butt 21 and a passage for the rear needle butt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com