Method and apparatus for cooling extruded soft tube made of plastic film

A technology of film hose and plastic film, applied in the field of tubular plastic film, can solve problems such as obstacles to increase production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

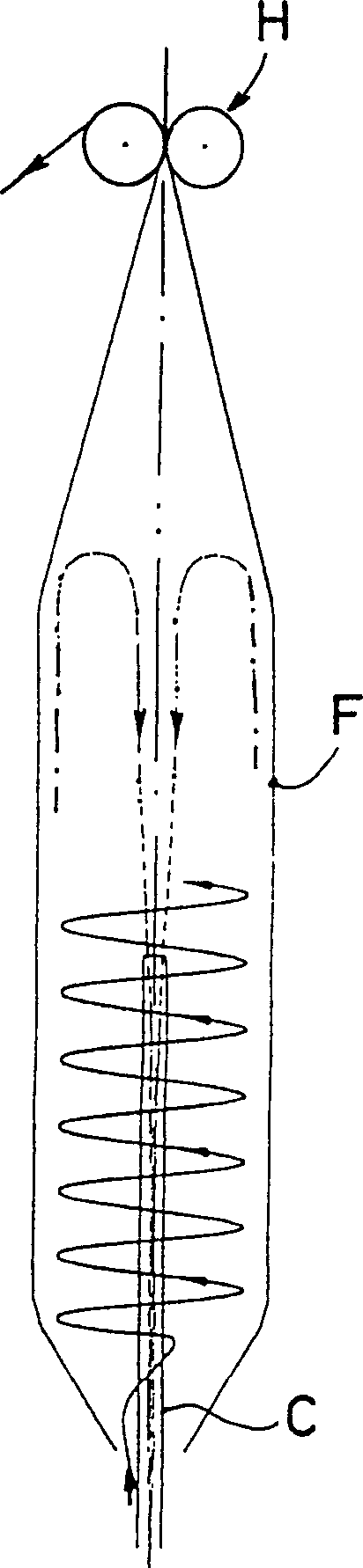

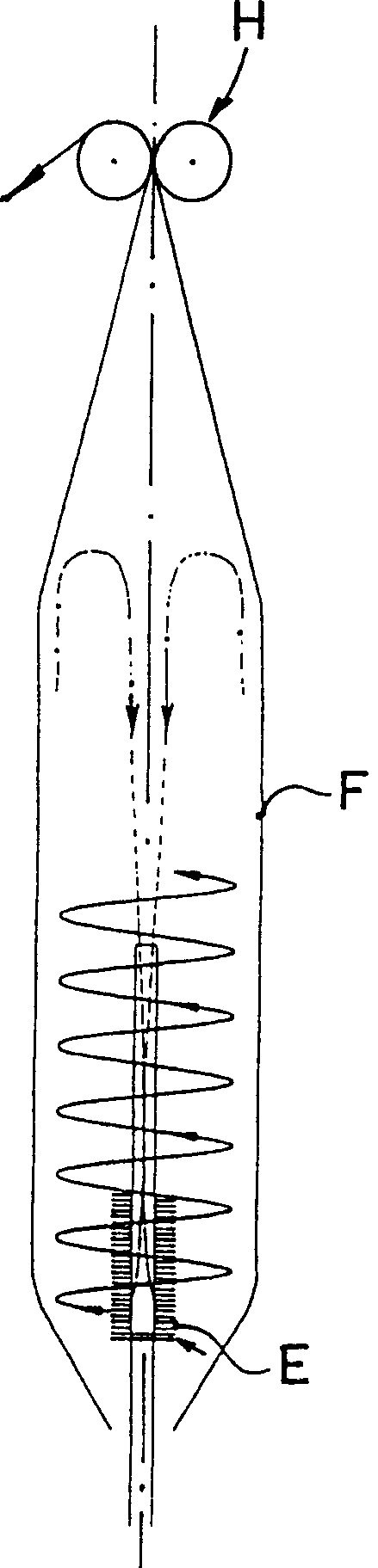

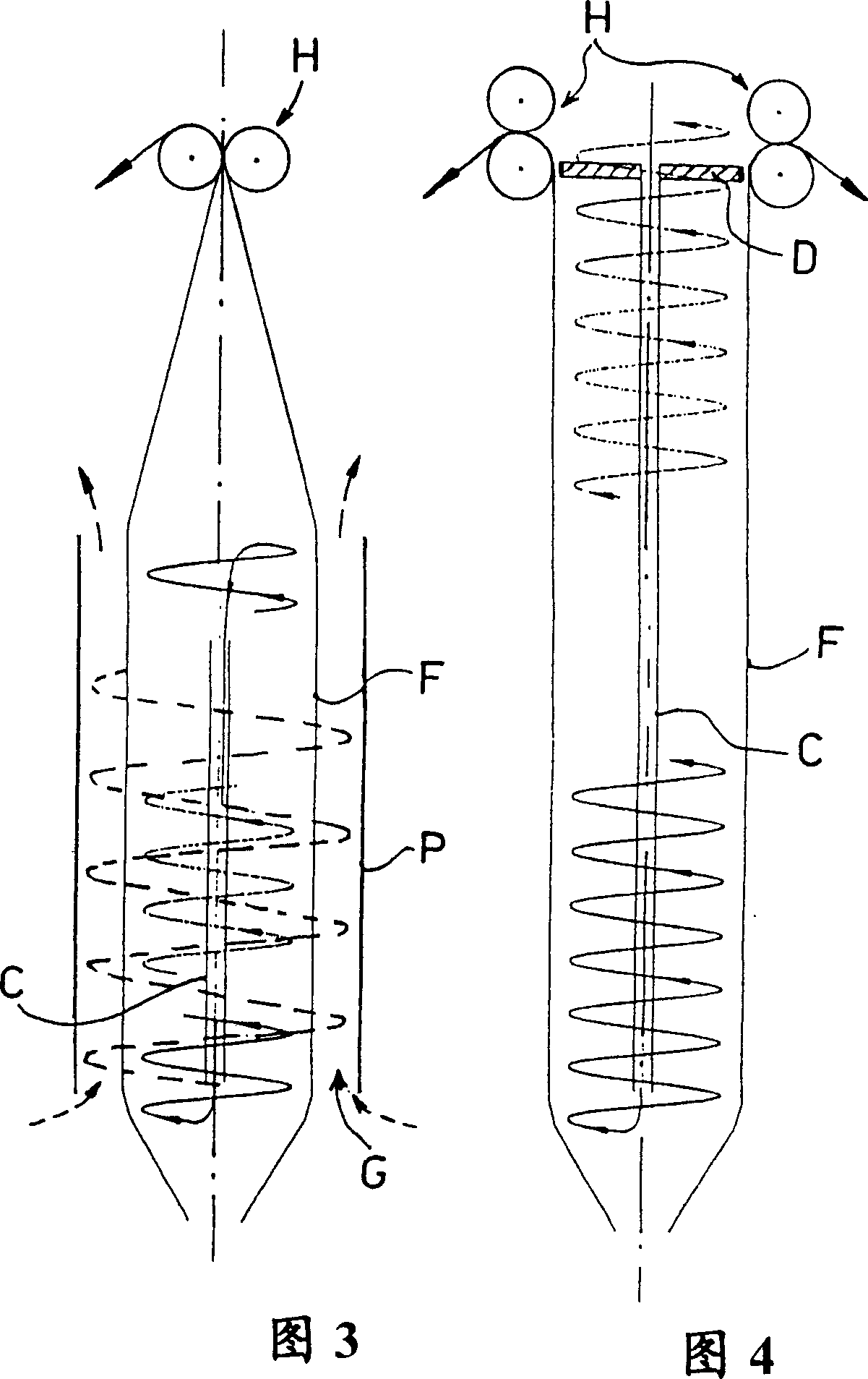

[0025] figure 1 Figure 4 shows a theoretical explanation and some potential implementations of the method and apparatus for film cooling according to the present invention.

[0026] refer to figure 1 , the first embodiment of the cooling technique according to the present invention shows a technique of internally cooling the film hose F just extruded from the nozzle hole (not shown) of the extruder. Pressurized air as coolant is fed in a transverse direction (as opposed to conventional delivery of coolant radially and in a direction parallel to the upward direction of hose advancement). In this way, the coolant flow is swirled (rotated) by the tangential inlet so that, according to the invention, due to the centrifugal force affecting the coolant flow along the inner surface of the film hose F, and the density difference between the different parts of the coolant flow and pressure difference, the coolant flow will follow a helical trajectory (shown as a solid line) in the cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com