Method and a machine for producing a tissue web

a tissue web and machine technology, applied in the field of tissue web production methods and machines, can solve the problems of affecting the quality of tissue webs, and affecting the quality of tissue webs, and achieves excellent macro scale topography, good optical properties, and excellent macro scale smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

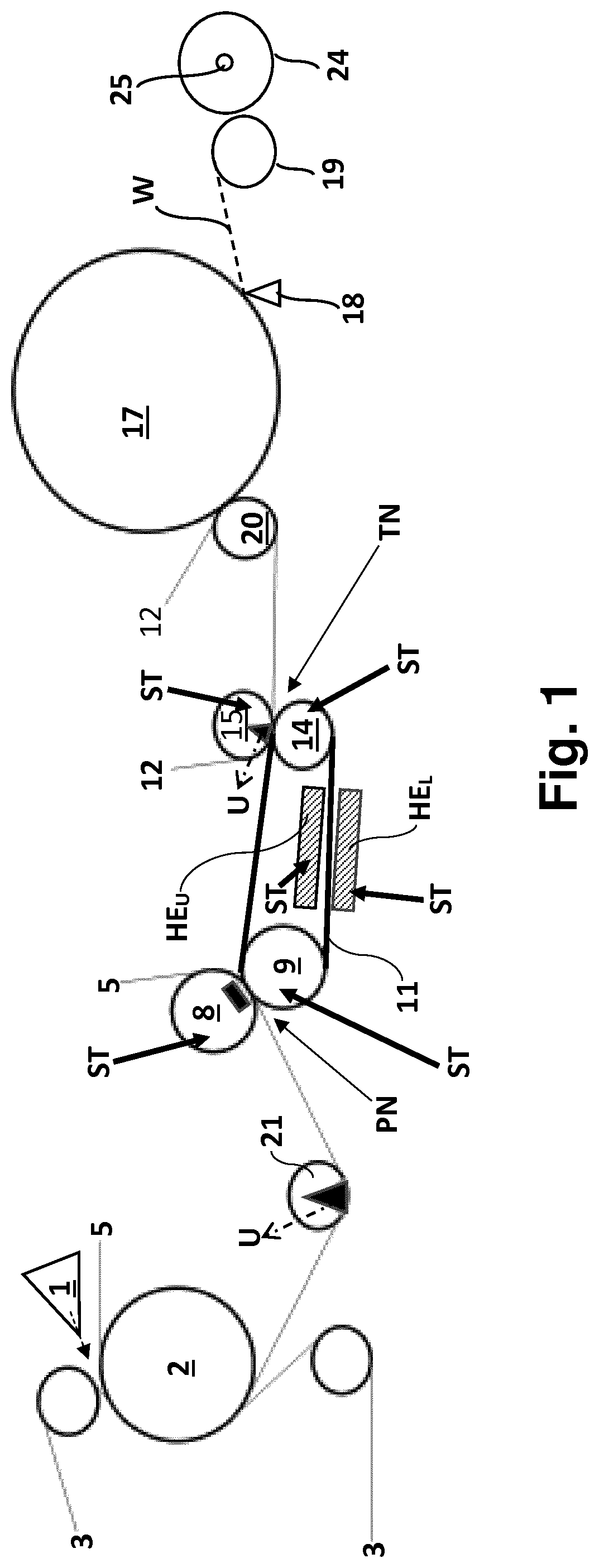

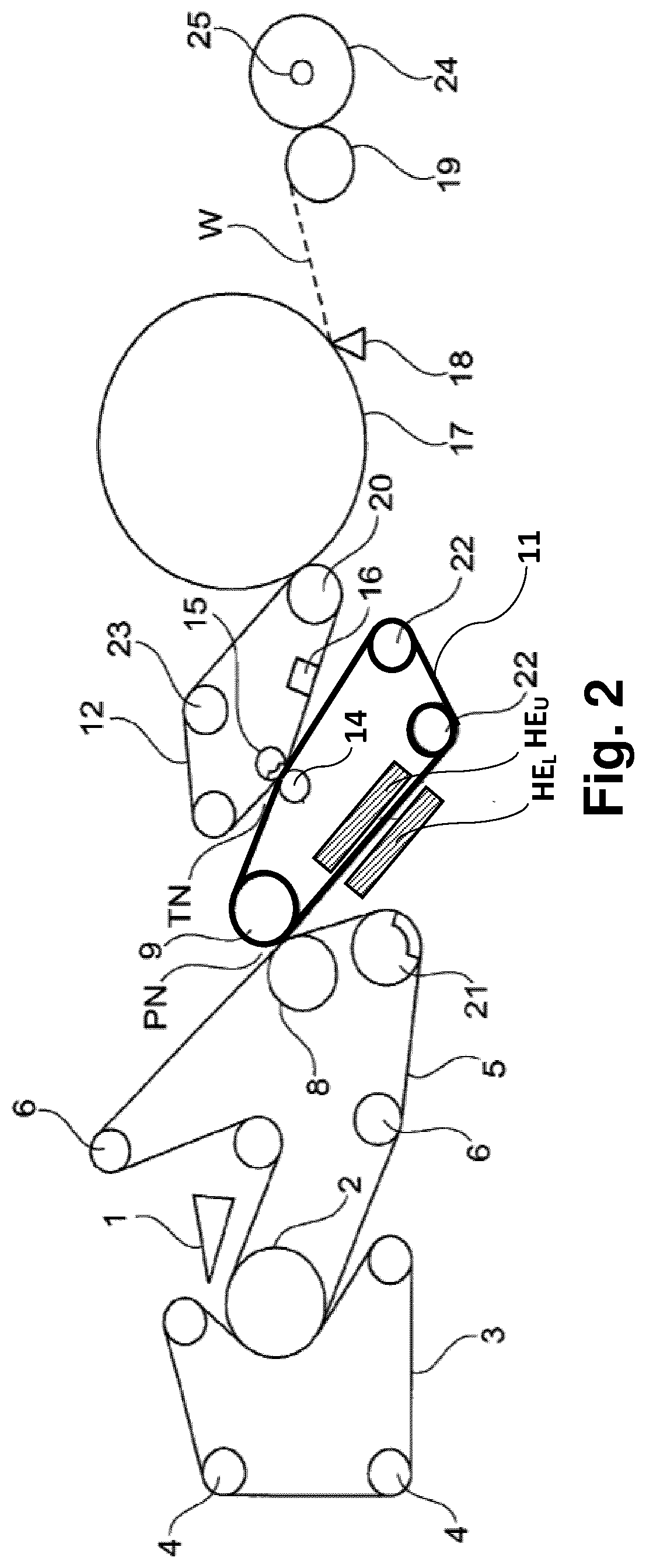

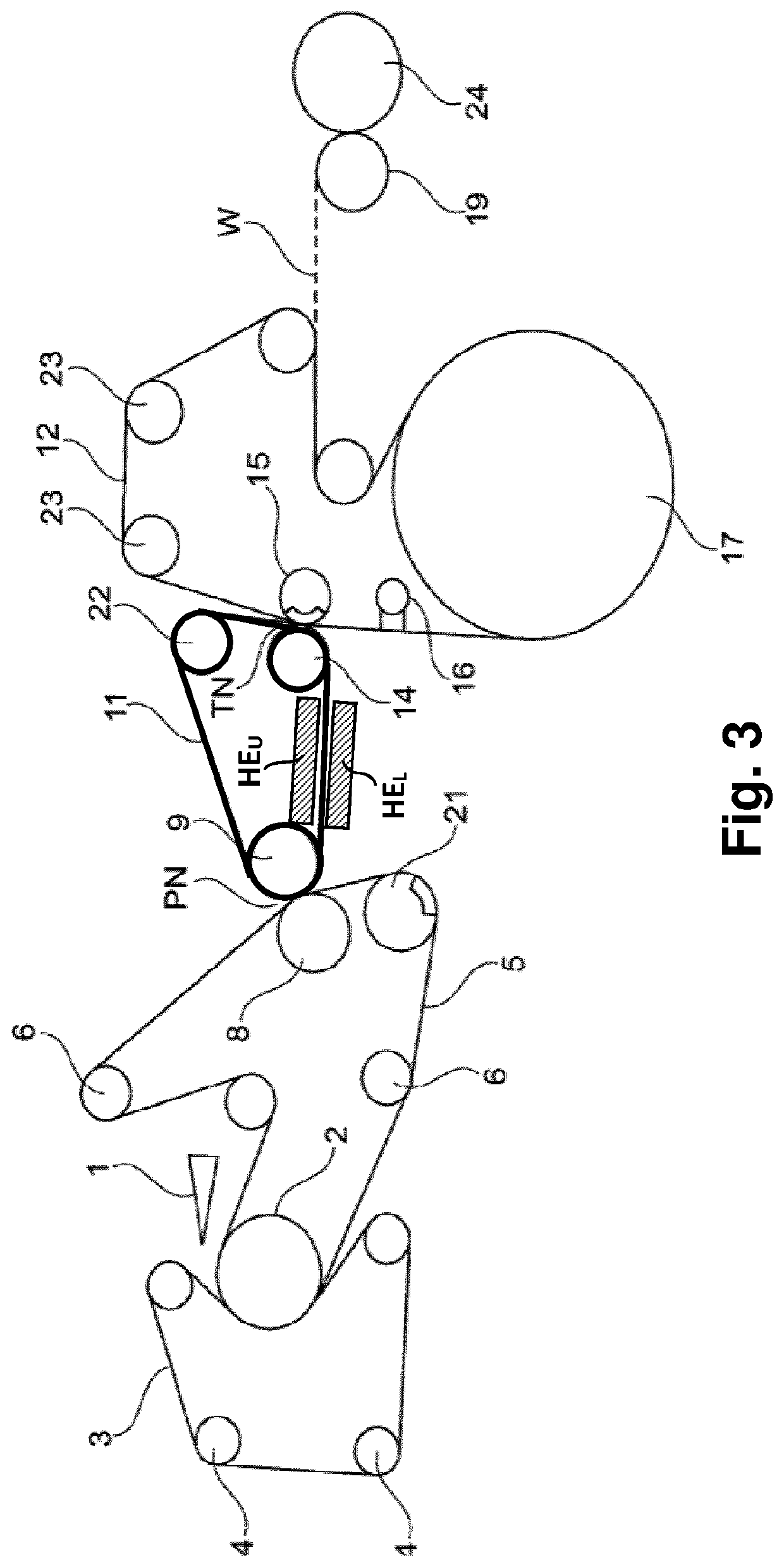

[0043]With reference to FIG. 1, a machine for producing a structured fibrous web of paper is shown. The machine comprises a forming section. The forming section has a head box 1 that is arranged to inject stock into a gap between a first forming fabric 3 and a second forming fabric 5. Both forming fabrics 3, 5 may be foraminous wires (i.e. wires that are permeable to water). However, in advantageous embodiments, the first forming fabric 3 is a foraminous wire while the second forming fabric 5 may be a water receiving felt. It should be understood that in the context of this patent application and any patent issuing therefrom, the term “forming fabric” is used for any fabric used during forming of the fibrous web. This could include both foraminous wires and felts.

[0044]The reference numeral 2 designates a forming roll. In FIG. 1, it is shown how the first forming fabric 3 is arranged to run in a loop guided by guide rolls 4, seen in FIG. 2. The second forming fabric 5 is guided by g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com