Sinker for loop cutting

A sinker and terry technology, used in textiles and papermaking, weft knitting, knitting, etc., can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

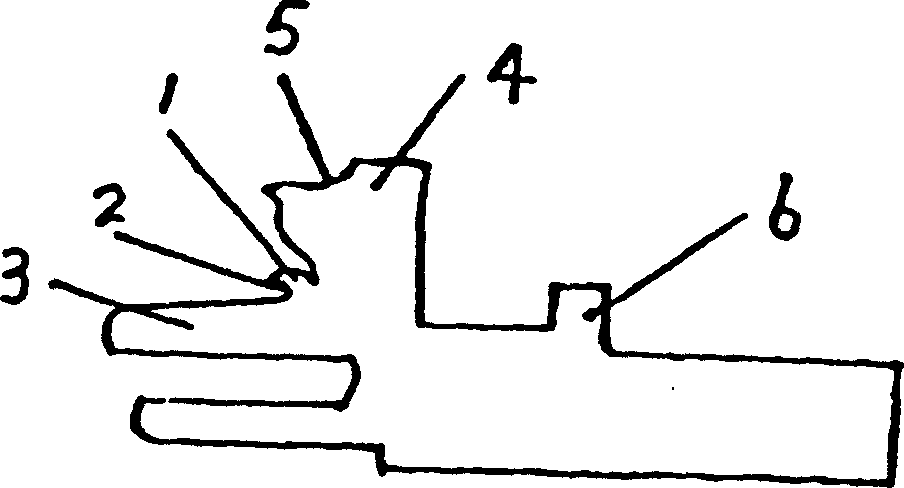

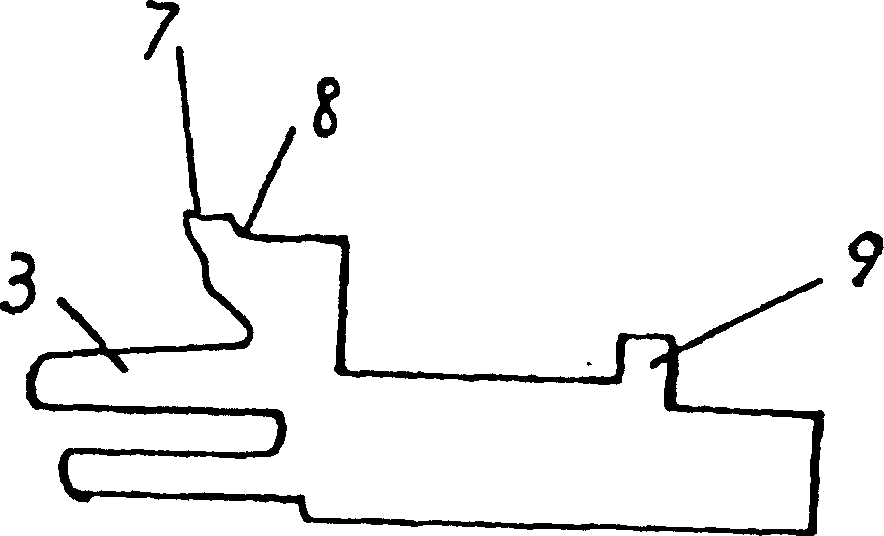

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings. The loop cut loop sinker is composed of sinkers at two positions of high and low heels. The high-heel sinker consists of a nose piece (1), a throat piece (2), a jaw piece (3), a high-heel piece crown (4), a high-heel piece crown blade (5) and a high-heel piece heel (6); The low-heel sinker is composed of a jaw (3), a low-heel crown (7), a low-heel crown blade (8) and a low-heel heel (9). Adopt 31 / 2 inches in the present embodiment, 96 pins single-cylinder towel machine, make ground yarn with 21 * 5 cotton yarns, 21 / 2 * 2 cotton threads are made terry yarns, weave single-sided terry cut loop fabric. The fabric is used for the water rubber roller cover (abbreviated as the water rubber roller fleece) on the printing machine. When weaving, its knitting process is the same as that of single-sided terry fabric. The sinker arc of the terry loop rests on the notches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com