Knotting spring clamping mechanism of full-automatic spring-coiling machine

A technology of spring clamping and coiling machine, which is used in the manufacture of springs, workpiece clamping devices, and other household appliances from wires, which can solve the problem of difficulty in ensuring the diameter of the spring at both ends of the spring, inconvenient adjustment, and difficulty in guaranteeing the quality of the spring. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

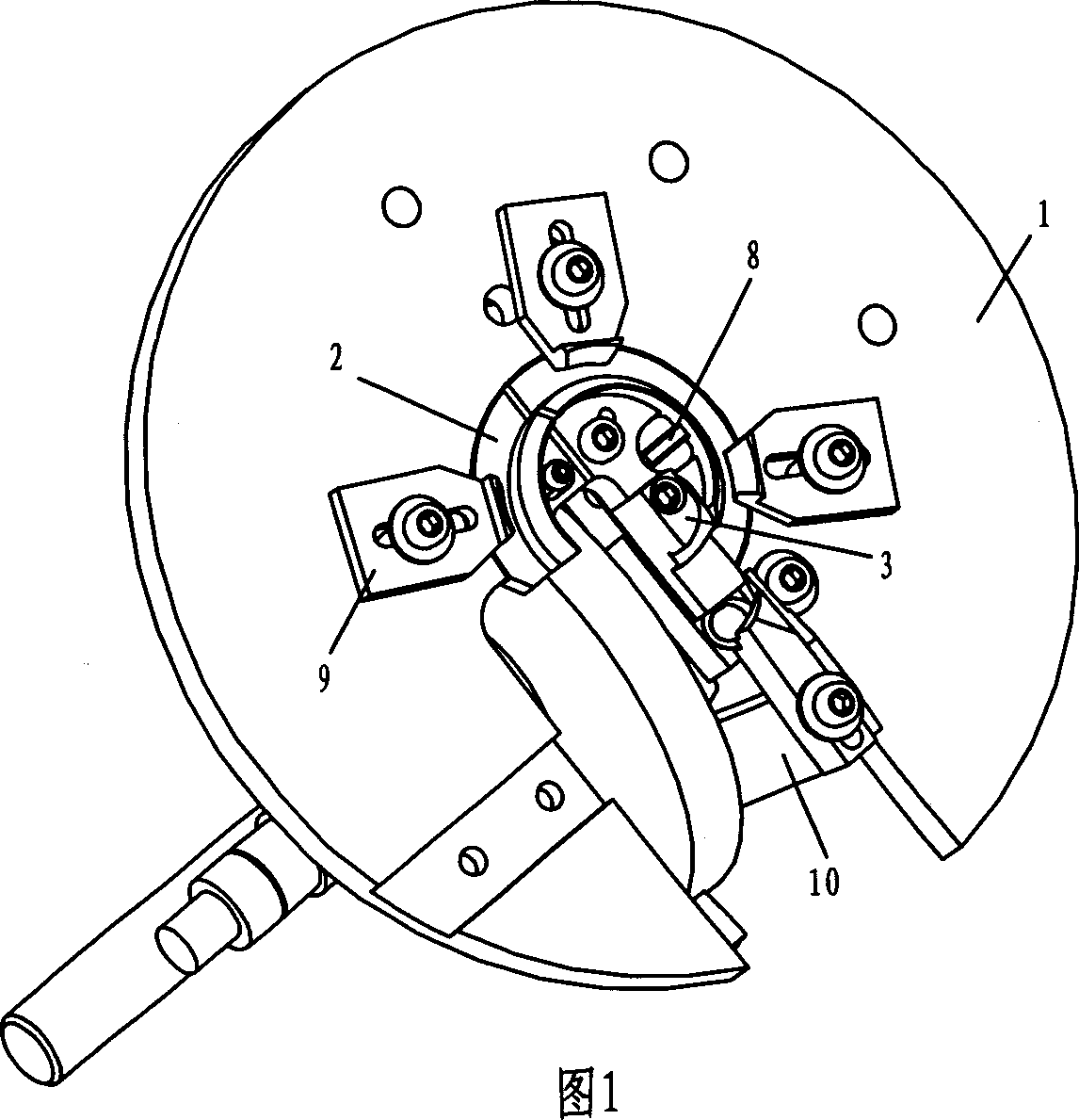

[0011] As shown in the figure (1, 2), it includes mounting plate 1, diameter disc 2, steel wire support 3, ejector rod cam 4, large gear disc cam 5, driving shaft 6, fixed shaft 7, ejector rod sliding device 8, clamping block Interlocking device 9, briquetting pressing device 10.

[0012] Such as image 3 As shown, the diameter disc 2 is composed of a diameter disc 2a, a diameter disc 2b and a connecting plate 2c. The connection plate 2c is embedded in the groove at the bottom of the diameter plate 2a and the diameter plate 2b, and the diameter plate 2a and the diameter plate 2b are connected together, the connection plate 2c and the diameter plate 2a are fixed on the installation plate 1, and the diameter plate 2b is fixed on the connection On the plate 2c, the long holes on it can be adjusted left and right along the two sides of the connecting plate to increase or decrease the diameter of the diameter disc.

[0013] Steel wire support 3 is fixed in the long hole of mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com