LED device and packing method thereof

A technology of LED device and packaging method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve problems such as limited improvement, and achieve the effect of enhancing lighting intensity and improving luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

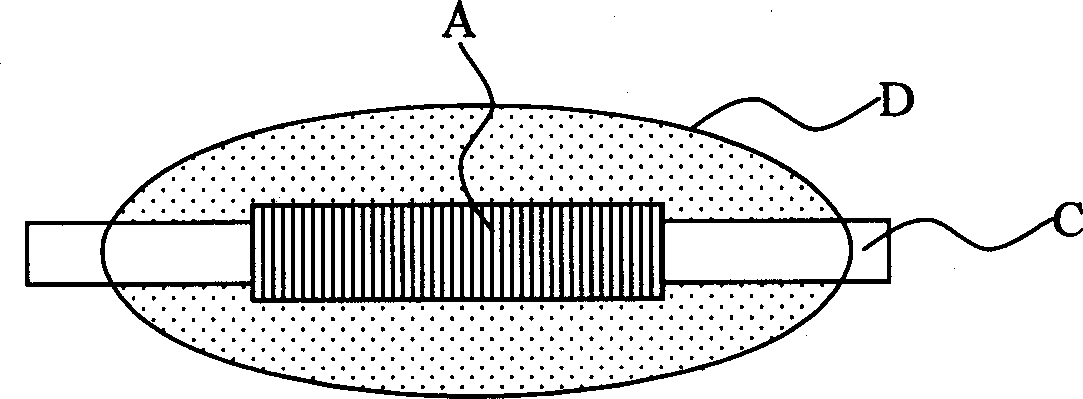

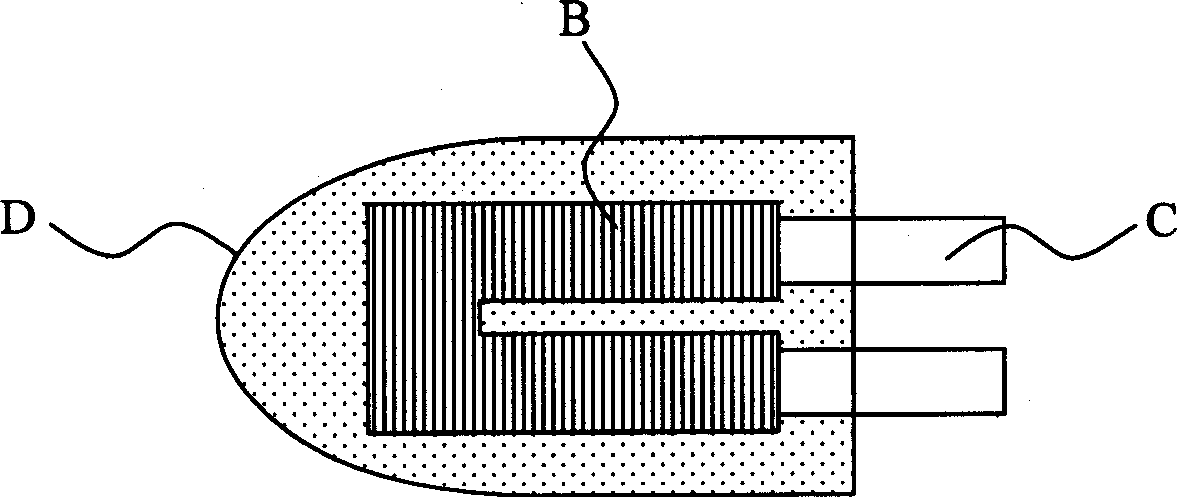

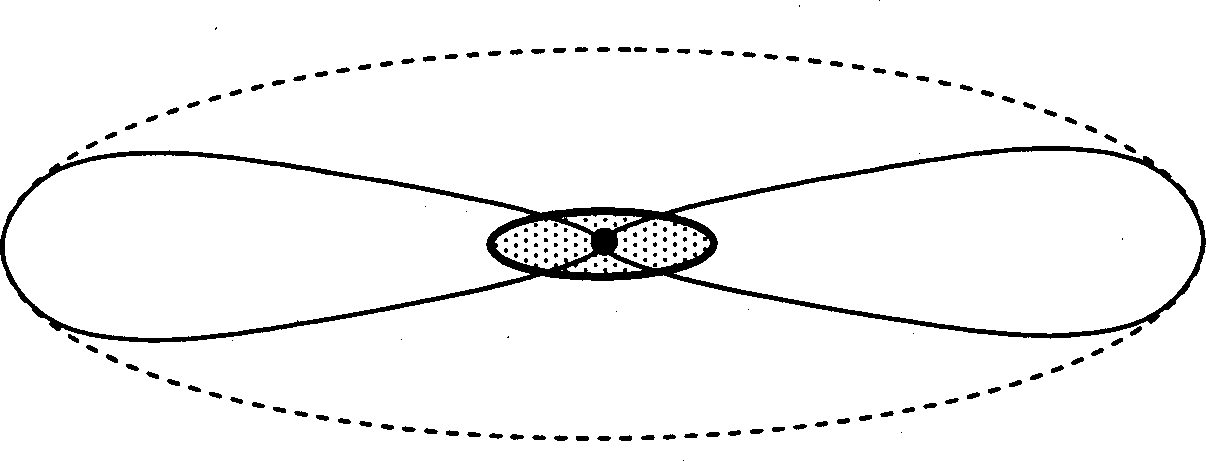

[0022] The invention provides an LED device with a liquid packaging structure and a packaging method thereof. The basic structure of the LED device includes LED tube cores, electrodes, light-transmitting shells and encapsulation liquid. The conductive end of the LED die is connected to an electrode, the light-transmitting housing seals the LED die and the encapsulation liquid, and the electrode passes through the housing to connect the LED die to an external circuit. The encapsulation liquid is a light-transmitting liquid with a high resistivity, and its resistivity is much larger than the conduction resistivity of the LED die.

[0023] The LED tube core in the present invention can adopt those existing materials and structures, and can be a single tube core or a combination of multiple tube cores, such as a plurality of tube cores connected in series or in parallel in a package structure. Same-color or different-color dies. The integrated die structure described in the Chin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com