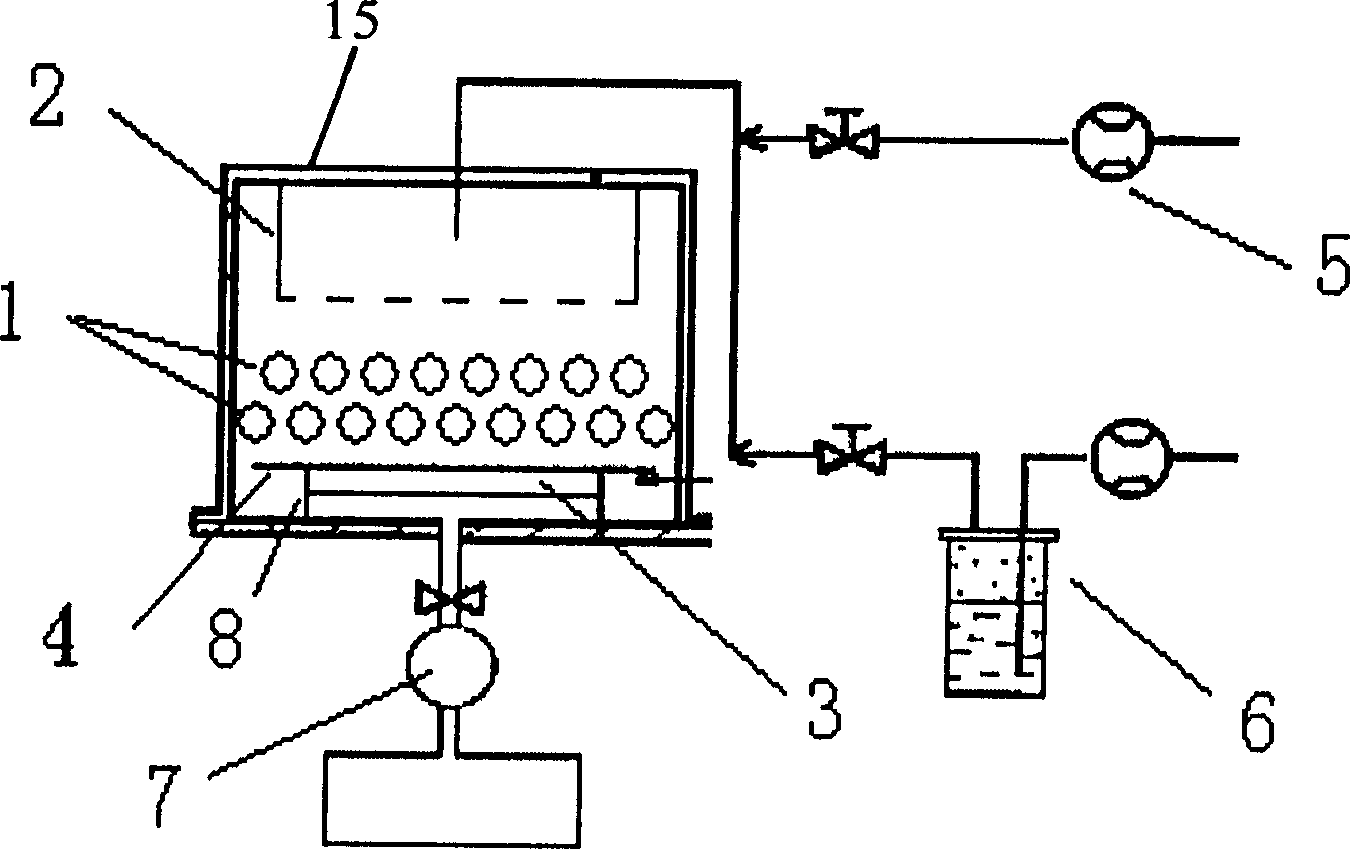

Method of atmospheric pressure plane discharge chemical gaseous phase depositing nano-particular film and its device

A chemical vapor deposition, atmospheric pressure technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of limited adjustment range, inability to achieve film structure transformation, damage to the surface of the substrate, etc. The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

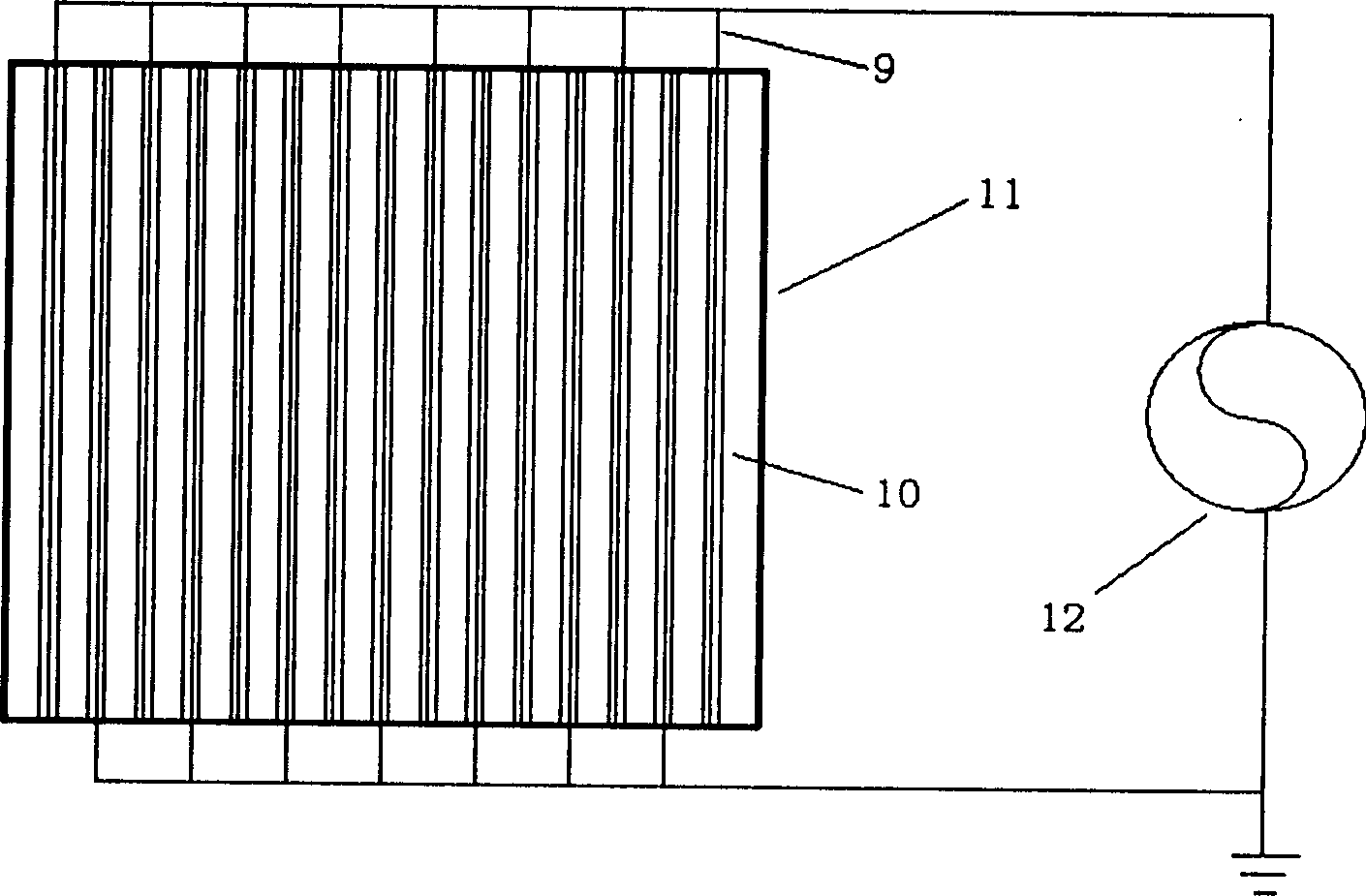

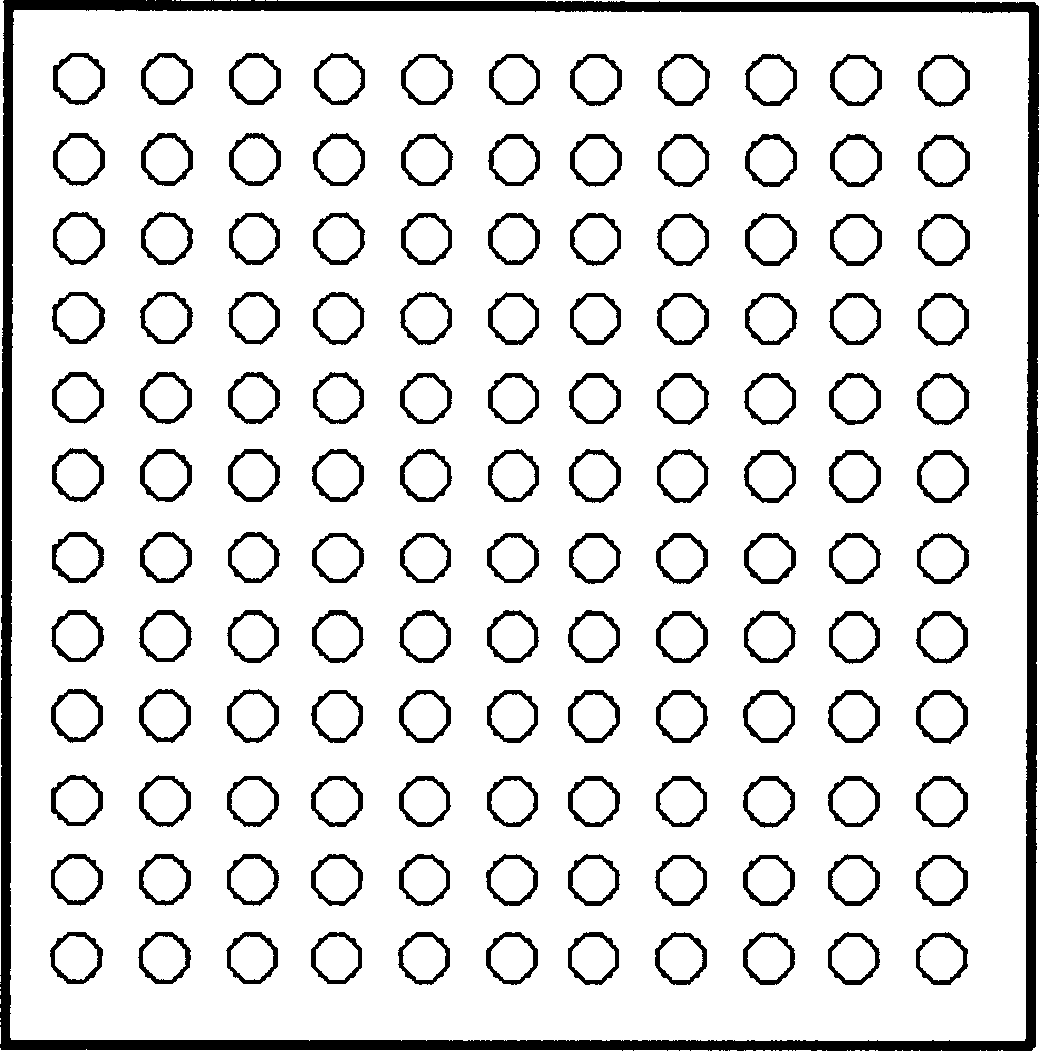

Embodiment 1

[0027] Place a planar discharge unit in the discharge area, place the cleaned substrate 4 (glass) on the metal platform 3, and use a mechanical pump 7 to vacuum the reactor to a certain extent. First, discharge auxiliary gas 5 (He, The flow rate is 1.5SLM) so that the system maintains a certain positive pressure on the gas outlet, and the high-frequency high-voltage power supply 12 (20kHz, 6.5kV) is turned on to observe the discharge state; then the volume ratio is 100:10. 4 The reaction gas 6 composed of chemical gas is passed into the reactor 15, the flow rate of the reaction gas is 100 SCCM, and the discharge appearance has obvious filamentous shape. When the discharge power is increased, the discharge appearance becomes uniform. Under the discharge power of 200W, the deposited film on the surface of the substrate is TiO nanoparticles 2 ,Such as Figure 5 Shown in (a); the distribution of the film thickness along the width of the electrode plane is as follows Figure 5 Sh...

Embodiment 2

[0029] Place the cleaned substrate 4 (cotton fabric and glass flakes for testing) on the metal platform 3, use a mechanical pump 7 to vacuum the reactor 15, and first feed the discharge auxiliary gas 5 (Ar, flow rate) in the system. is 2.0SLM), then will be determined by O 4 with TiCl 4 The chemical gas is passed into the reactor 15 with the reaction gas 6 having a volume ratio of 100:5, and the flow rate of the reaction gas is 200 SCCM. Turn on the high-frequency high-voltage power supply 12, and the reaction consists of a single planar discharge unit (power is 200W, power frequency is 22kHz, voltage is 7.0kV) and two planar discharge units (power is 400W, power frequency is 17kHz, voltage is 11.0kV) When excited, the surface composition of the deposited film is as Figure 6 Shown in (a) and (b). Figure 6 (a) shows that when the thickness of the discharge area is thin (single planar discharge unit), the gas reaction is not sufficient, and the deposited film contains Cl ...

Embodiment 3

[0031] A planar discharge unit is placed in the discharge area, the cleaned substrate (glass) is placed on the metal platform 3, and the reactor 15 is vacuumed to a certain extent with the mechanical pump 7, and the discharge auxiliary gas 5 (He, The flow rate is 0.5SLM) so that the system maintains a certain positive pressure on the air outlet, and the high-frequency high-voltage power supply 12 (20kHz, 8.0kV) is turned on, and then the O 2 with TiCl 4 The chemical gas is passed into the reactor 15 in the reaction gas 6 with a volume ratio of 100:10, and the flow rate of the reaction gas is 50 SCCM. Connect the metal plate of the air distributor 2 and the metal platform 3 to the positive and negative poles of the electrostatic high-voltage power supply respectively, that is, add an electrostatic high-voltage field in the direction of gas transportation, adjust the distance between the metal platform and the metal plate of the air distributor to 1.5cm, and apply static electri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com