Technology of synthesizing 2,3-dicyano ethyl propionate

A technology of ethyl dicyanopropionate and ethyl cyanoacetate, which is applied in the preparation of cyanide reaction, organic chemistry, etc., can solve the problem of large loss of ethanol solvent, low yield of ethyl 3-cyanopropionate, and high price. Advanced problems, to achieve the effect of reducing production costs, good product quality, and small dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: The following is an industrial production embodiment.

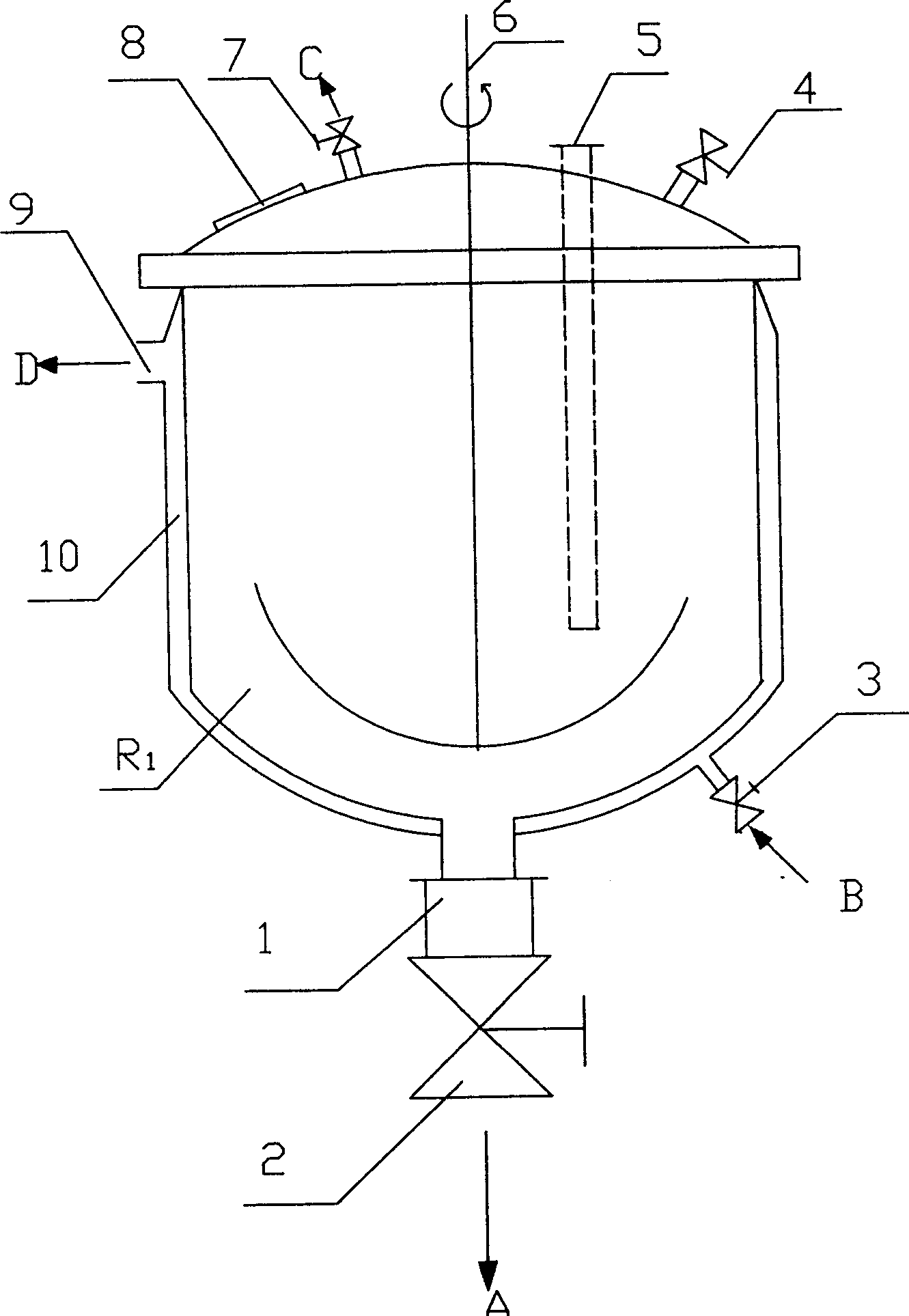

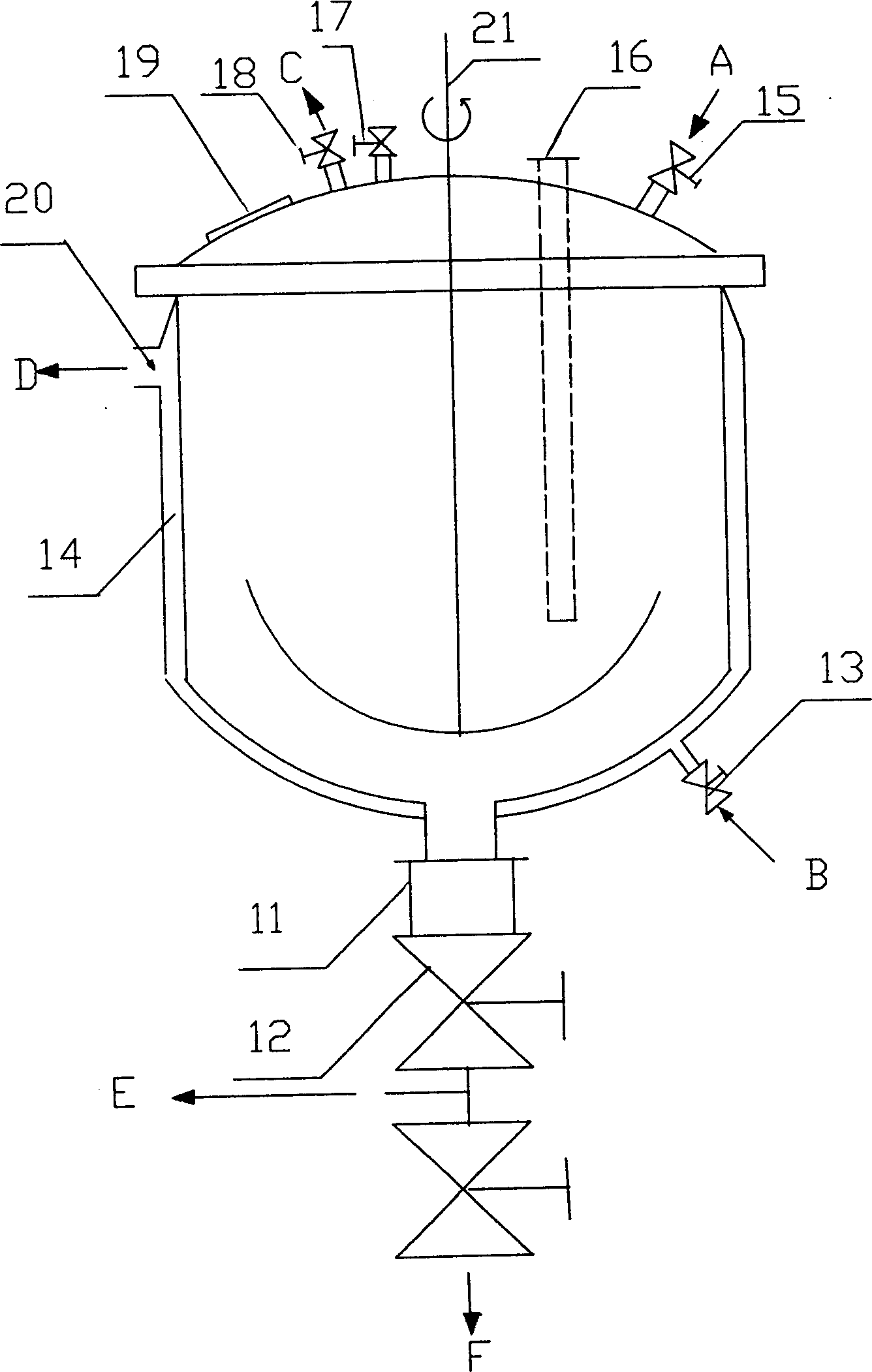

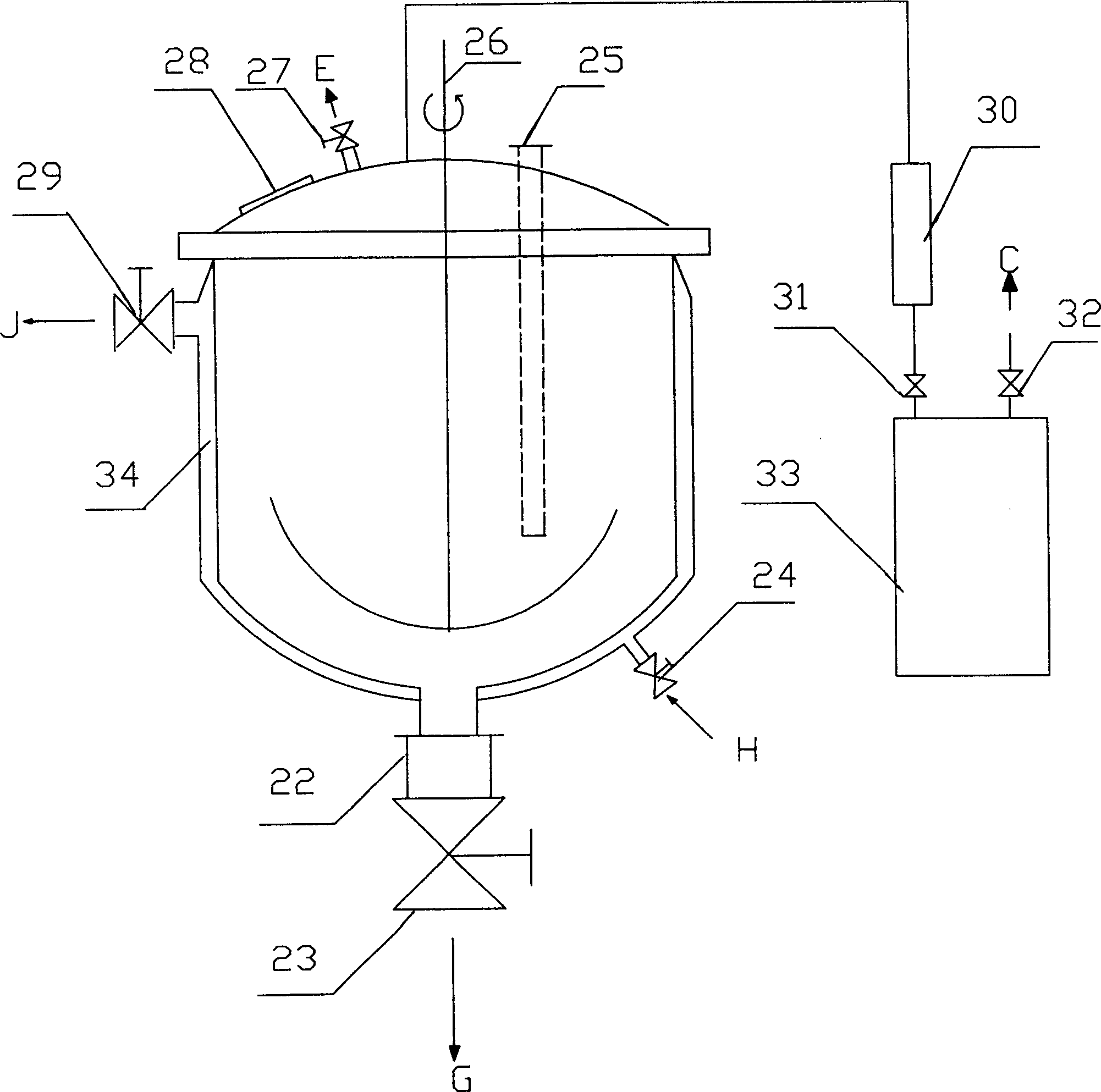

[0024] see figure 1 , figure 2 , image 3 and Figure 4 .

[0025] 1. Use the following raw materials and reaction medium:

[0026] Ethyl cyanoacetate raw material content: >99%.

[0027] Raw material content of paraformaldehyde: 93-95%.

[0028] The sodium cyanide raw material of solid matter is an industrial superior product.

[0029] The reaction medium is dimethyl sulfoxide, its content: ≥98%.

[0030] 2. Take 3 barrels of medium dimethyl sulfoxide liquid, about 600-650 kg and 95 kg of raw material ethyl cyanoacetate liquid, from figure 1 The reaction kettle R1 can be seen, open the vacuum valve (7) in the 1500-liter glass-lined reaction kettle R1, and connect the vacuum pipeline through the vacuum direction C to the vacuum pump, so that the reaction kettle R1 is under negative pressure, and the liquid material is discharged from the suction port valve (4) Pump into the reaction kettle R...

Embodiment 2

[0059] 1, the raw material that adopts and reaction medium are identical with embodiment 1.

[0060] 2. Inhale 6 barrels of medium dimethyl sulfoxide (about 1200 kg to 1300 kg) and 190 kg of raw material ethyl cyanoacetate from the liquid material suction valve (4) of the reactor R1 into the reactor, and turn on the mixer (6), And open the cooling brine valve (3) so that the brine enters the kettle inner jacket (10) from the inlet direction B to cool down through the cooling brine outlet (9), and the cooling brine flows back to the brine storage tank in the direction D.

[0061] 3. Add 100 kilograms of solid raw material sodium cyanide and 50 kilograms of paraformaldehyde into the kettle from the manhole (8) of the reactor R1.

[0062] 4. Close the manhole cover of the manhole (8) of the reactor R1, make the temperature of the material in the reactor R1 be 10° C. to 30° C. by the above-mentioned cooling brine, and react under normal pressure for about 20 hours.

[0063] 5. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com