Composite membrane bioreactor

A membrane bioreactor, biological reaction tank technology, applied in sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc. Ideal and other issues, to achieve the effect of optimizing hydraulic conditions, saving energy consumption for aeration, and reducing decarbonization load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

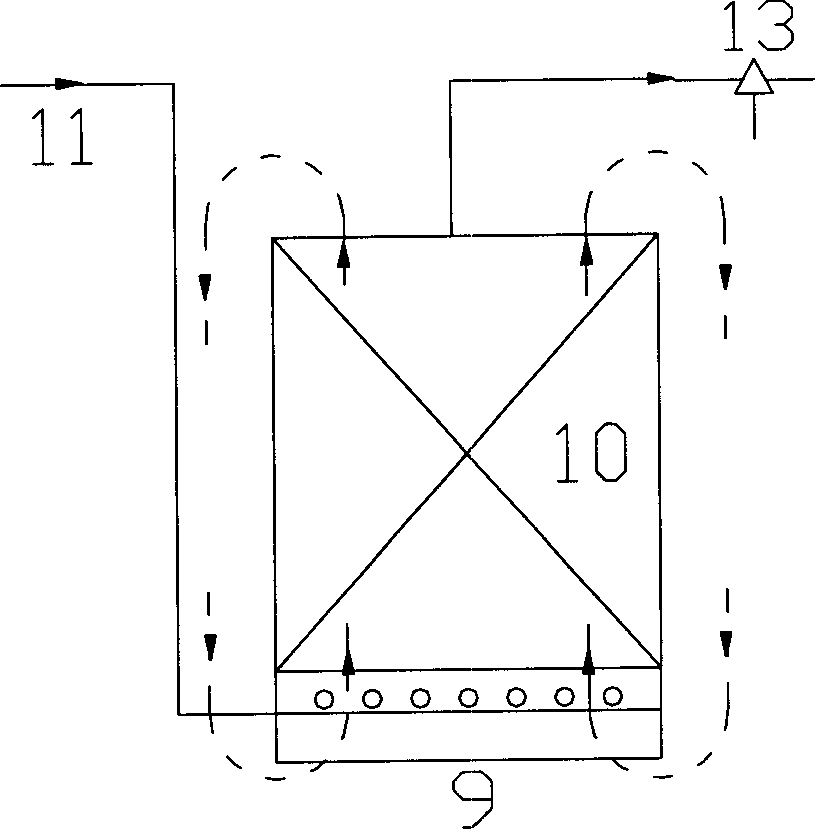

[0019] The specific implementation method is: the sewage enters the anoxic zone, and under the anoxic environment, by contacting with the microorganisms attached to the biofilm of the packing layer (3) in the anoxic zone, the organic matter is initially degraded, and then the water flows from the compartment deflector ( 4) The lower part enters the aerobic zone, and then the organic pollutants in the water are further treated through the filler (6) in the aerobic zone, and the muddy water entering the membrane module is pre-filtered, and part of the water entering the membrane module is pumped The pump (16) or relies on the gravity head pressure to draw water out of the membrane box (10), and the other part circulates inside and outside the membrane box or flows back into the anoxic zone. When the pressure difference between the inside and outside of the diaphragm rises significantly, the water outlet is stopped, and the online liquid cleaning is carried out according to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com