Photosensitive composition for forming light shading film, black bottom formed from said light shading film for photosensitive composition

A technology of photosensitive composition and light-shielding film, applied in the direction of photosensitive materials used in opto-mechanical equipment, etc., can solve the problems of poor sensitivity and decreased permeability, and achieve the improvement of transmittance, sensitivity, and sensitivity. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0090] Examples of the present invention are described below, but the present invention is by no means limited thereto.

[0091] (Synthesis example of resin)

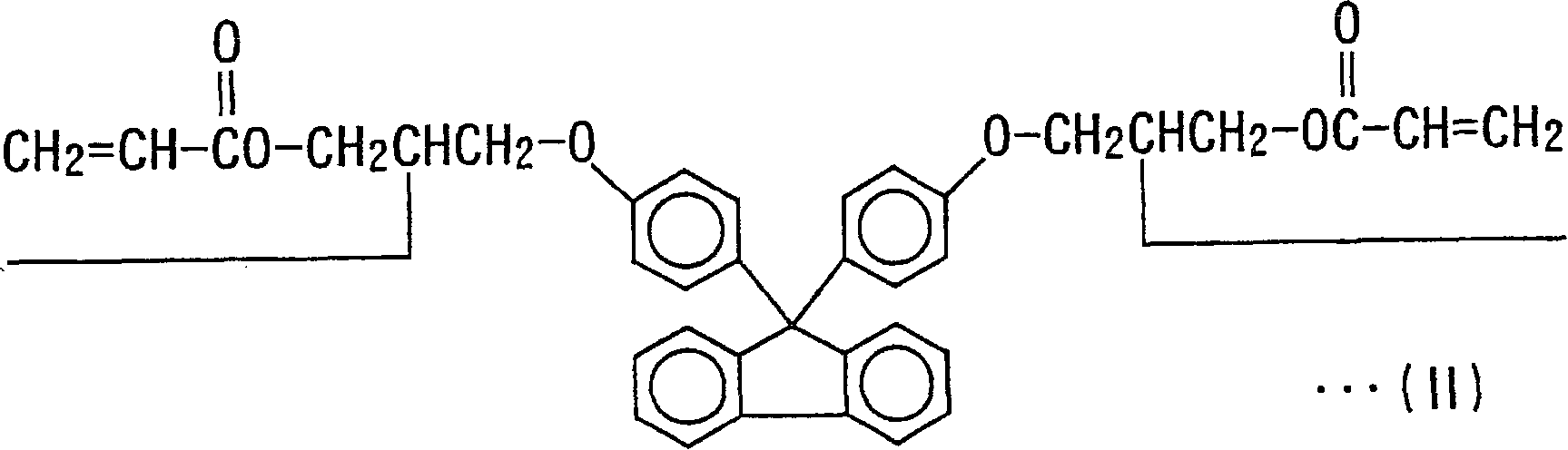

[0092] According to the record of JP-A-2001-354735, 235 g of bisphenol fluorene type epoxy resin (235 epoxy equivalents) and 110 mg of tetramethylammonium chloride, 2,6-di-tert-butyl-4- 100 mg of methylphenol and 72.0 g of acrylic acid were heated and dissolved at 90-100°C while blowing air thereinto at a rate of 25 mL / min. Next, while the solution was kept cloudy, the temperature was gradually raised, and it was heated to 120° C. to completely dissolve it. Wherein the solution gradually turns into a transparent viscous state, and the stirring is continued in this state.

[0093] Meanwhile, the acid value was measured, and heating and stirring were continued until it became 1.0 mgKOH / g or less. It takes 12 hours for the acid value to reach the target value. Then, it cooled to room temperature, and the bisphenol fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dispersed particle size | aaaaa | aaaaa |

| Dispersed particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com