Gear device

A technology of gear devices and internal gears, which is applied in the direction of gear transmission devices, winch devices, transmission devices, etc., can solve the problems of the decrease of the coaxiality of the central axis, the increase of cost, and the decrease of the roundness of the ring part of the internal gear, etc. Effects of retention, improvement of bonding strength, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment

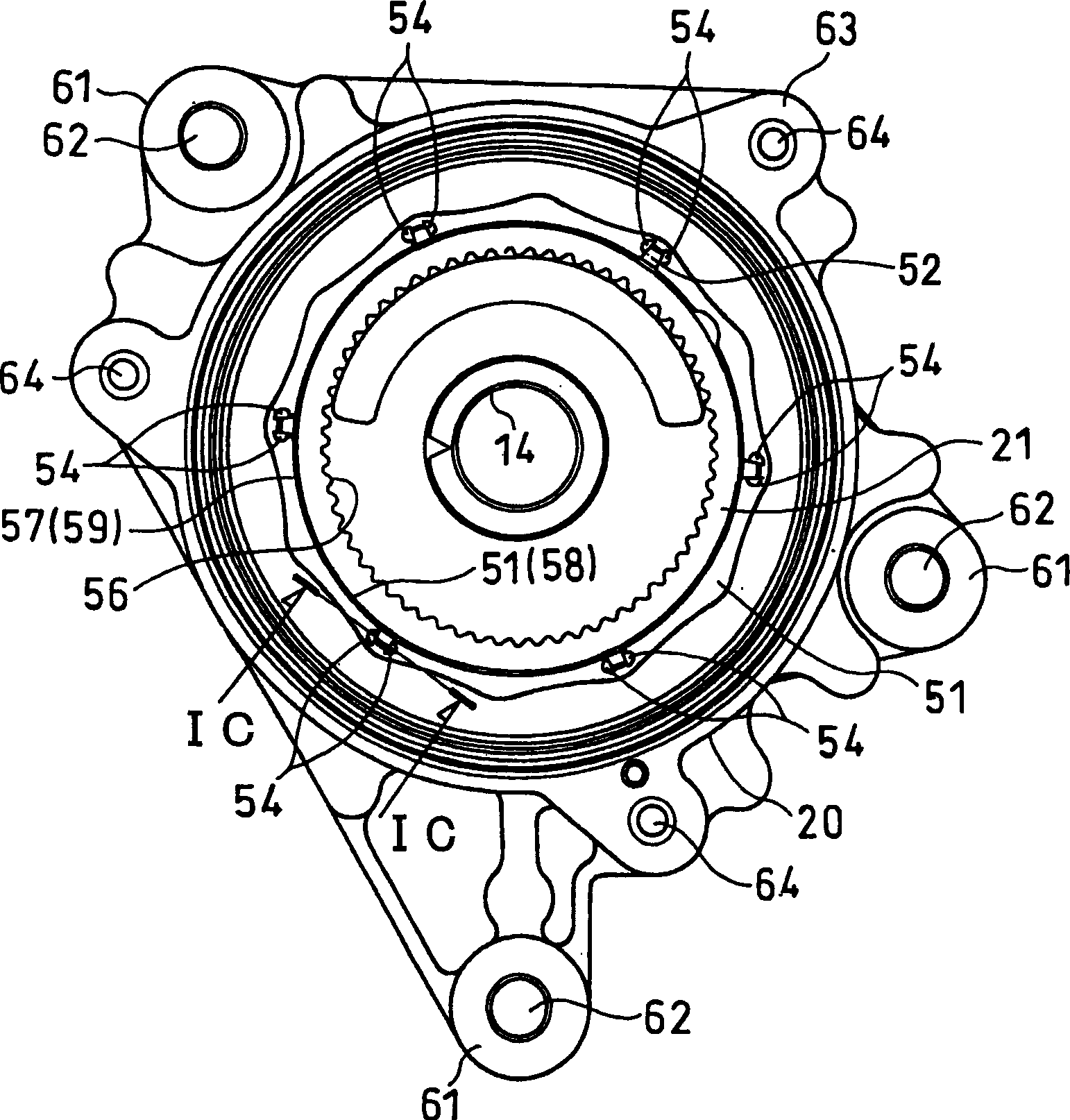

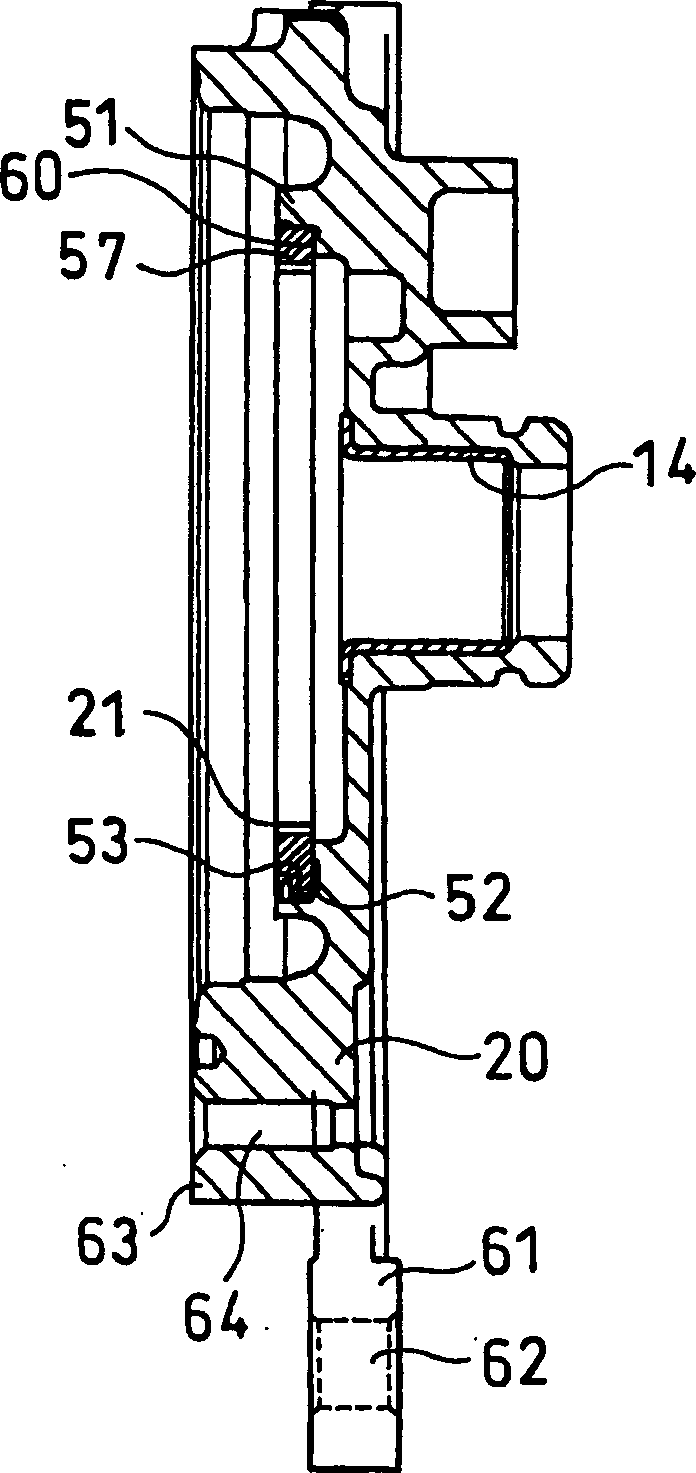

[0068] Figure 4B And what Fig. 5 represented is the 2nd embodiment of the present invention, Figures 4A-4B as well as Figures 5A-5B Shown are the engagement claws of the internal gear of the reduction gear unit and the engagement grooves of the front housing.

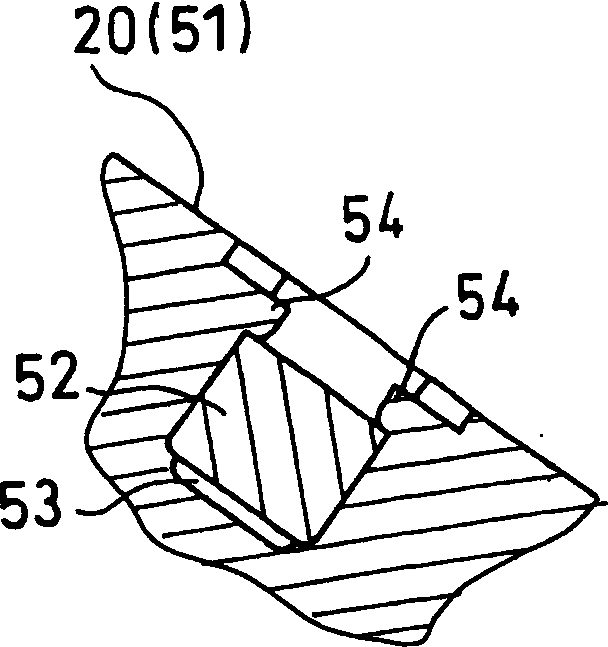

[0069] Figure 4A It shows that in the reduction gear device of the first embodiment, the outer peripheral portion of the annular portion 57 of the internal gear 21 is press-fitted into the inner peripheral portion of the fitting wall 51 of the front housing 20, and the The state when the plurality of engaging claws 52 on the outer peripheral portion of the annular portion 57 of the internal gear 21 are fitted into the plurality of engaging grooves 53 provided on the inner peripheral portion of the fitting wall 51 of the front housing 20 .

[0070] At this time, the small gap between the circumferential side surface of the engaging claw 52 and the circumferential side wall surface of the engaging groove 53 is usua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com