Tyre element assembly drum

A technology for forming drums and tires, which is applied to tires, other household appliances, household appliances, etc., and can solve the problems of reducing the forming accuracy of the tread reinforcement layer B, deterioration, and deterioration of the forming accuracy of rubber parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, one embodiment of the present invention will be described based on the drawings.

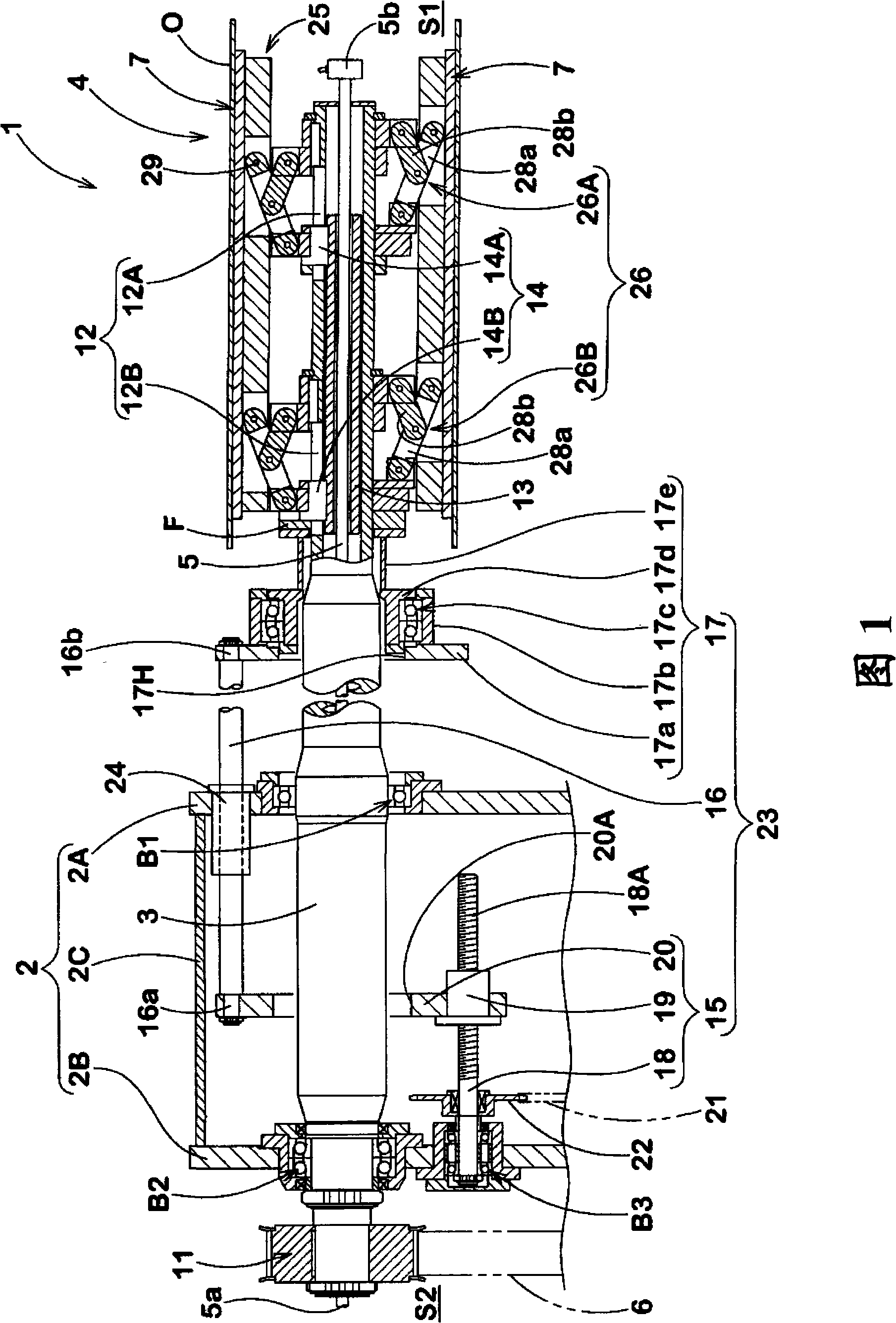

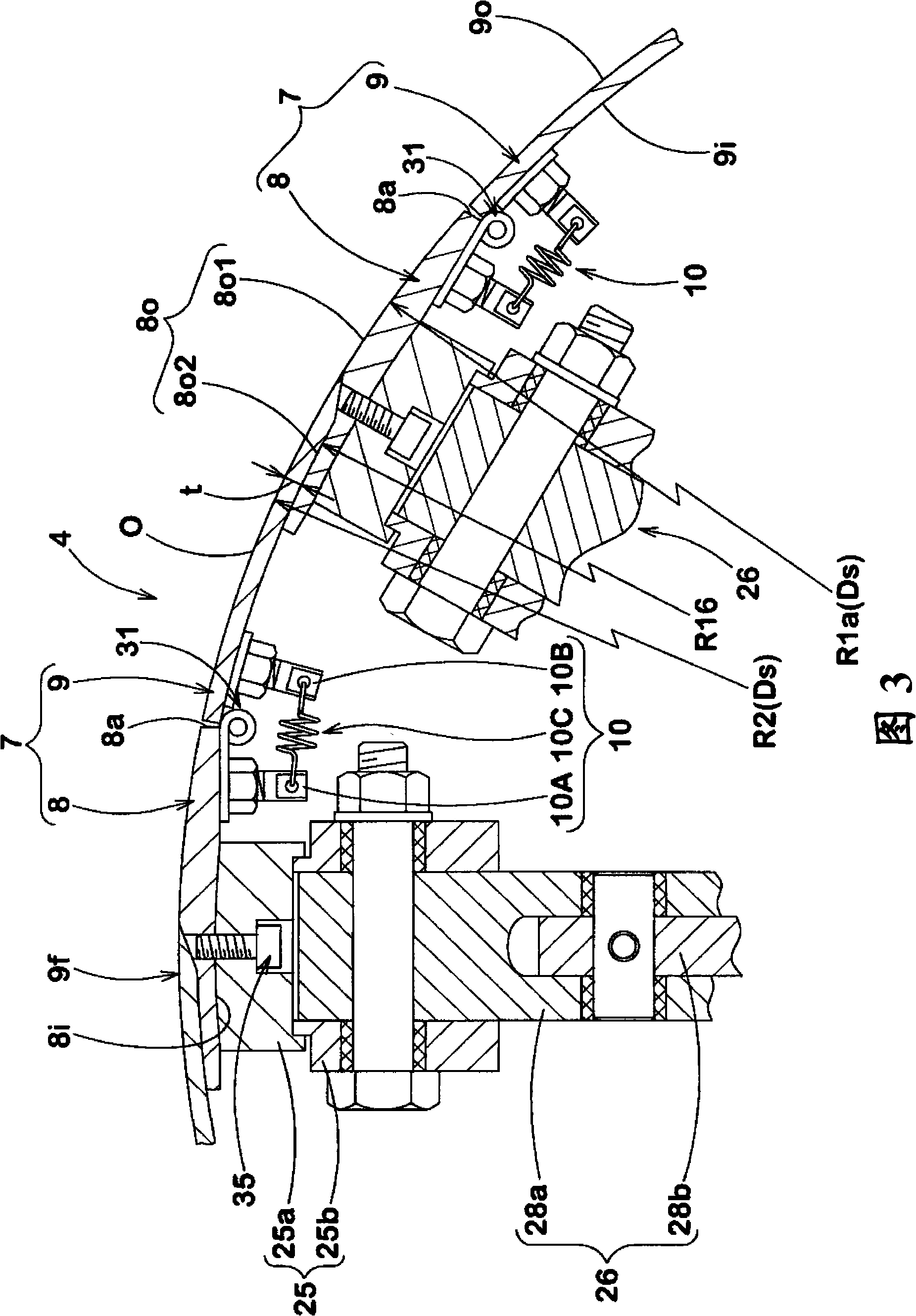

[0030] figure 1 It is a partial sectional view showing the forming drum 1 of this embodiment, figure 2 is an enlarged view showing its main part, image 3 yes means figure 2 A-A partial enlarged cross-sectional view. The building drum 1 in the figure includes: a main body frame 2; a horizontal central shaft 3, which is rotatably and cantilever-supported by bearings B1 and B2 provided on the main body frame 2; a drum main body 4, which is supported by the central shaft 3 It supports and has an approximately cylindrical drum outer peripheral surface O. Here, in this manual, the figure 1 The drum main body 4 side (right side) in the illustration will be described as one end side S1, and the opposite side will be described as the other end side S2.

[0031]The main body frame 2 includes: a first side wall portion 2A disposed on one end side S1 and having a bearing B1; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com