A method for planning the machining trajectory of a laminated material hole

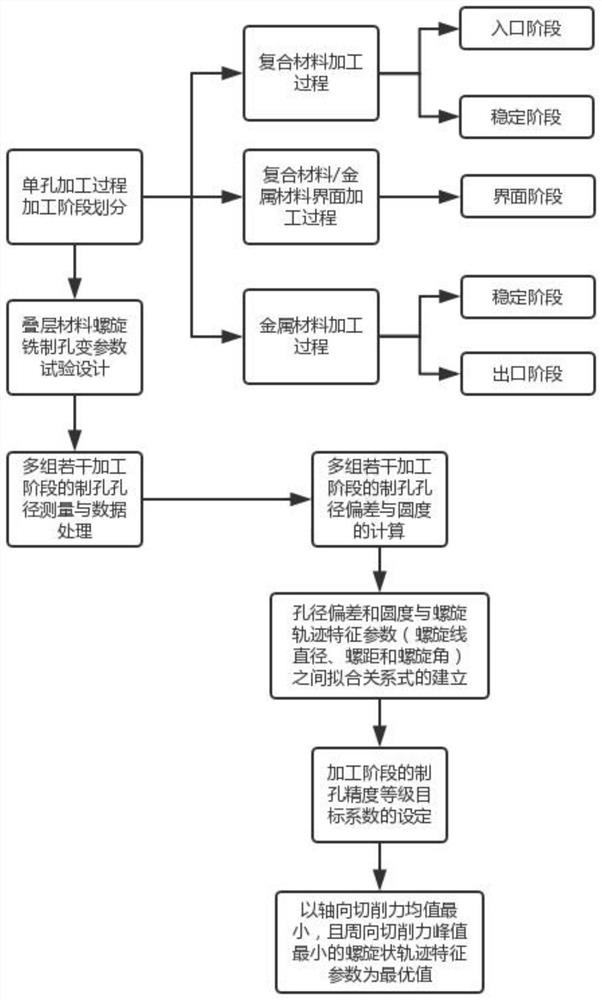

A technology of laminated materials and trajectory planning, applied in the direction of manufacturing tools, metal processing equipment, milling machine equipment, etc., can solve the problems of dividing processing stages, reducing the revolution speed of terminal hole-making actuators, and not significantly improving processing defects, etc., to achieve The effects of reducing hole diameter deviation and roundness, improving overall processing quality, and improving overall hole-making accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

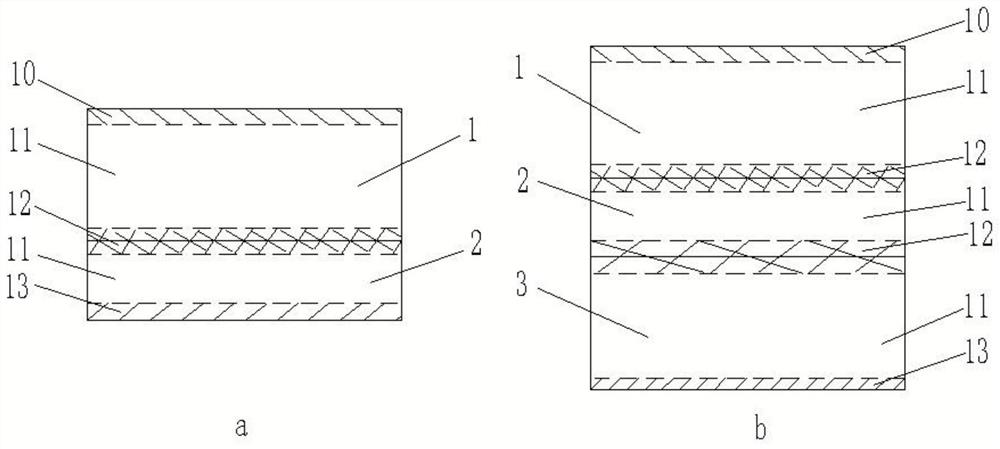

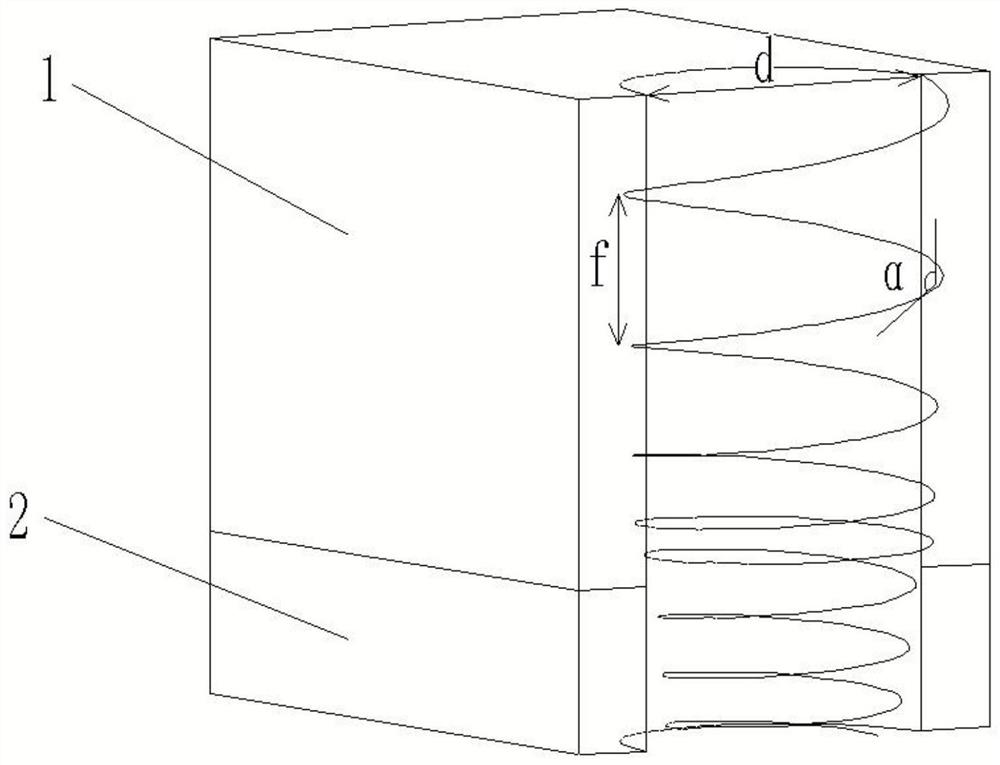

[0050] According to the composition of the laminated material, determine the thickness of the workpiece material and the aperture range: the double-layered laminated material is composed of the upper layer of CFRP composite material and the lower layer of titanium alloy, wherein the thickness of the titanium alloy material layer ranges from 5-10mm, and the thickness of the CFRP composite material layer is titanium alloy 2 times the thickness of the layer, the diameter range of the machining hole is 10-20mm, and the ratio of the hole diameter to the tool diameter is 1.5.

[0051] Using a traditional end mill, combined with the helical milling hole end effector under the industrial robot platform, the hole making process of double-layer laminated materials is implemented. The helical milling hole end effector used in the present invention is the prior art, which generally includes a tool The rotation unit, the tool revolution unit, the tool radial offset unit, the axial feed unit...

Embodiment 2

[0062] According to the composition of laminated materials, the thickness and aperture range of workpiece materials are determined: sandwich laminated materials are composed of upper layer CFRP composite material, middle layer titanium alloy and lower layer CFRP composite material. Among them, the thickness range of the titanium alloy material layer is 5-7mm, and the thickness of the CFRP composite material layer is twice the thickness of the titanium alloy layer. The diameter range of the machined hole is 15-30mm, and the ratio of hole diameter to tool diameter is 1.3.

[0063] Using a traditional end mill, combined with the helical milling hole end effector under the platform of the industrial numerical control machine tool to implement the hole making process to the sandwich laminated material, the helical milling hole end effector used in the present invention is the prior art, which generally includes The tool rotation unit, the tool revolution unit, the tool radial offse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com