Dyeing waste-water decolorizing degradation, recovery and utilization

A dyeing wastewater and decolorization technology, applied in chemical instruments and methods, textile industry wastewater treatment, adsorption water/sewage treatment, etc. Union, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

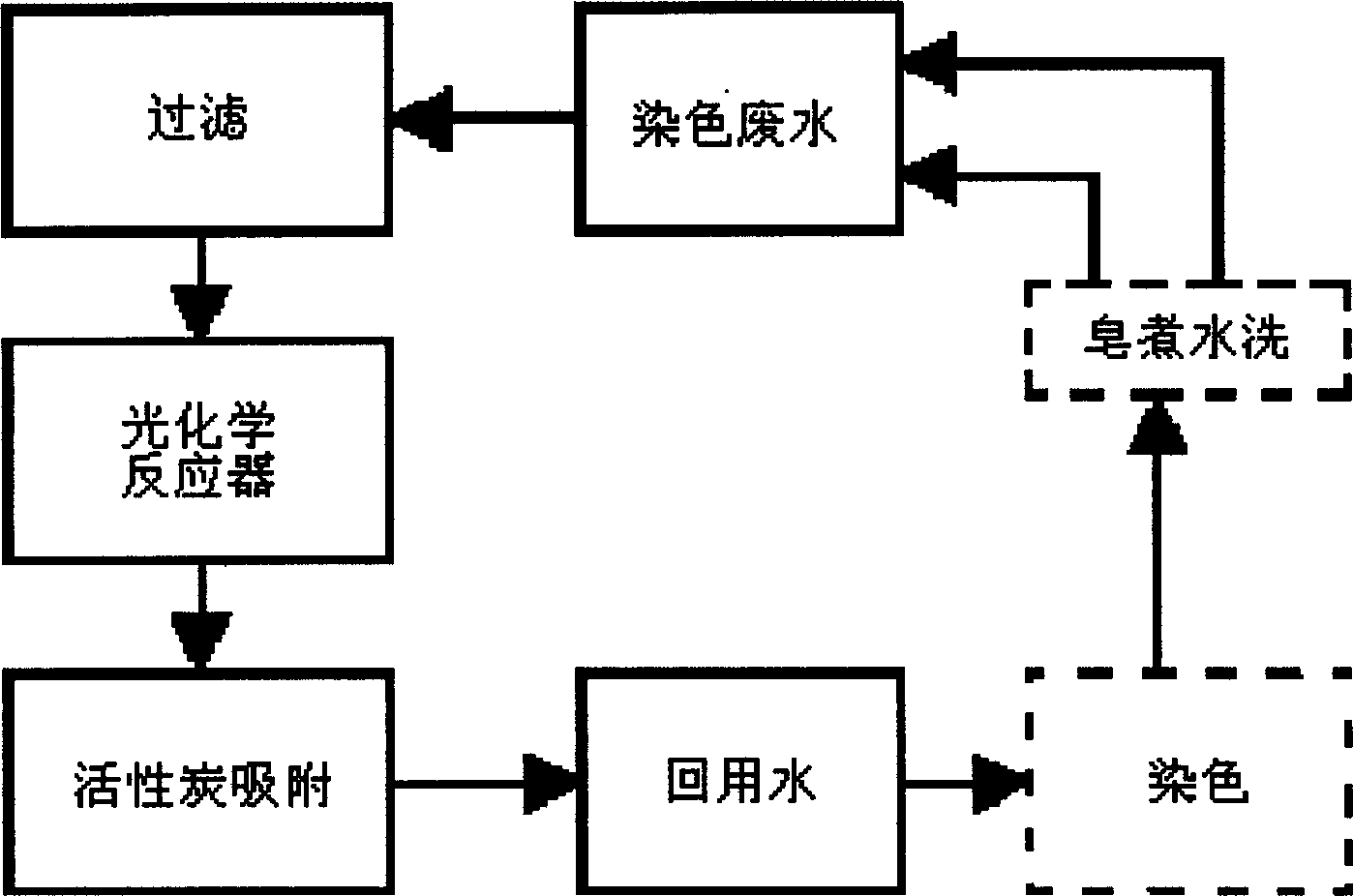

[0029] (Oxidation method) The target wastewater is the wastewater discharged from the processes of cotton fabric dyeing, soaping and washing.

[0030] Step 1: The dyeing wastewater is treated by a filtration process. The filter unit is mainly composed of a porcelain funnel (with 7# qualitative ordinary filter paper included), a glass collection bottle and a suction filter device. The middle is connected by a silicone tube and a rubber stopper. The filtration rate is controlled at about 0.25 liters / minute to obtain filtered wastewater.

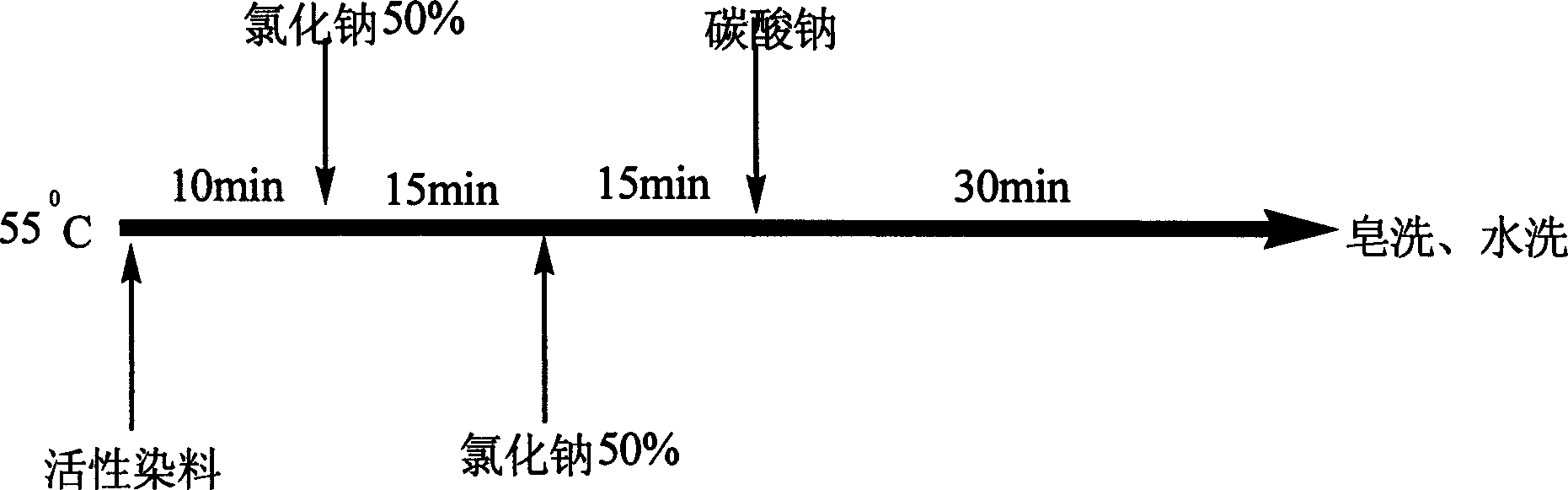

[0031] Step 2: use the photochemical reaction decolorization degradation process to filter the wastewater for treatment. Firstly, dilute sulfuric acid is used to adjust the pH value of filtered waste water, and then the photocatalytic oxidant is prepared according to the ratio of iron sulfate, oxalic acid and hydrogen peroxide in a molar ratio of 1:3:5. The decolorization process is as follows: add 0.50ml of photocatalytic oxidant to 100ml of ...

Embodiment 2

[0041] Step 1: Filtration speed is controlled at about 0.5 liter / minute, the rest is the same as in Example 1.

[0042] Step 2: use the photochemical reaction decolorization degradation process to filter the wastewater for treatment. Firstly, dilute sulfuric acid is used to adjust the pH value of filtered waste water, and then the photocatalytic oxidant is prepared according to the ratio of iron sulfate, oxalic acid and hydrogen peroxide in a molar ratio of 1:3:5. The decolorization process is as follows: add 2.50ml of photocatalytic oxidant to 100ml of dyed wastewater into the filtered wastewater, stir it evenly and place it in a water-cooled temperature-controlled photochemical reactor (patent No. ZL03275610.0), at a temperature of 21°C React with pH about 2.0 for about 15 minutes to obtain decolorized wastewater. The reuse results are shown in Table 5, Table 6 and Table 7.

[0043]

color properties

total color difference

S...

Embodiment 3

[0051] Step 1: Filtration speed is controlled at about 0.2 liters / minute, and the remainder is the same as in Example 1.

[0052] Step 2: use the photochemical reaction decolorization degradation process to filter the wastewater for treatment. Firstly, dilute sulfuric acid is used to adjust the pH value of filtered waste water, and then the photocatalytic oxidant is prepared according to the ratio of iron sulfate, oxalic acid and hydrogen peroxide in a molar ratio of 1:3:5. The decolorization process is as follows: Add 5.0ml of photocatalytic oxidant to 100ml of dyed wastewater to filter wastewater, stir evenly, and place it in a water-cooled temperature-controlled photochemical reactor (patent No. ZL03275610.0), at a temperature of 22°C React with pH about 5.0 for about 10 minutes to obtain decolorized wastewater. The reuse results are shown in Table 8, Table 9 and Table 10.

[0053]

color properties

total color difference

S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com