Absorbing article

A technology for absorbency and articles, applied in the direction of absorbent pads, clothing, underwear, etc., can solve the problem that the shape stability cannot be fully obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

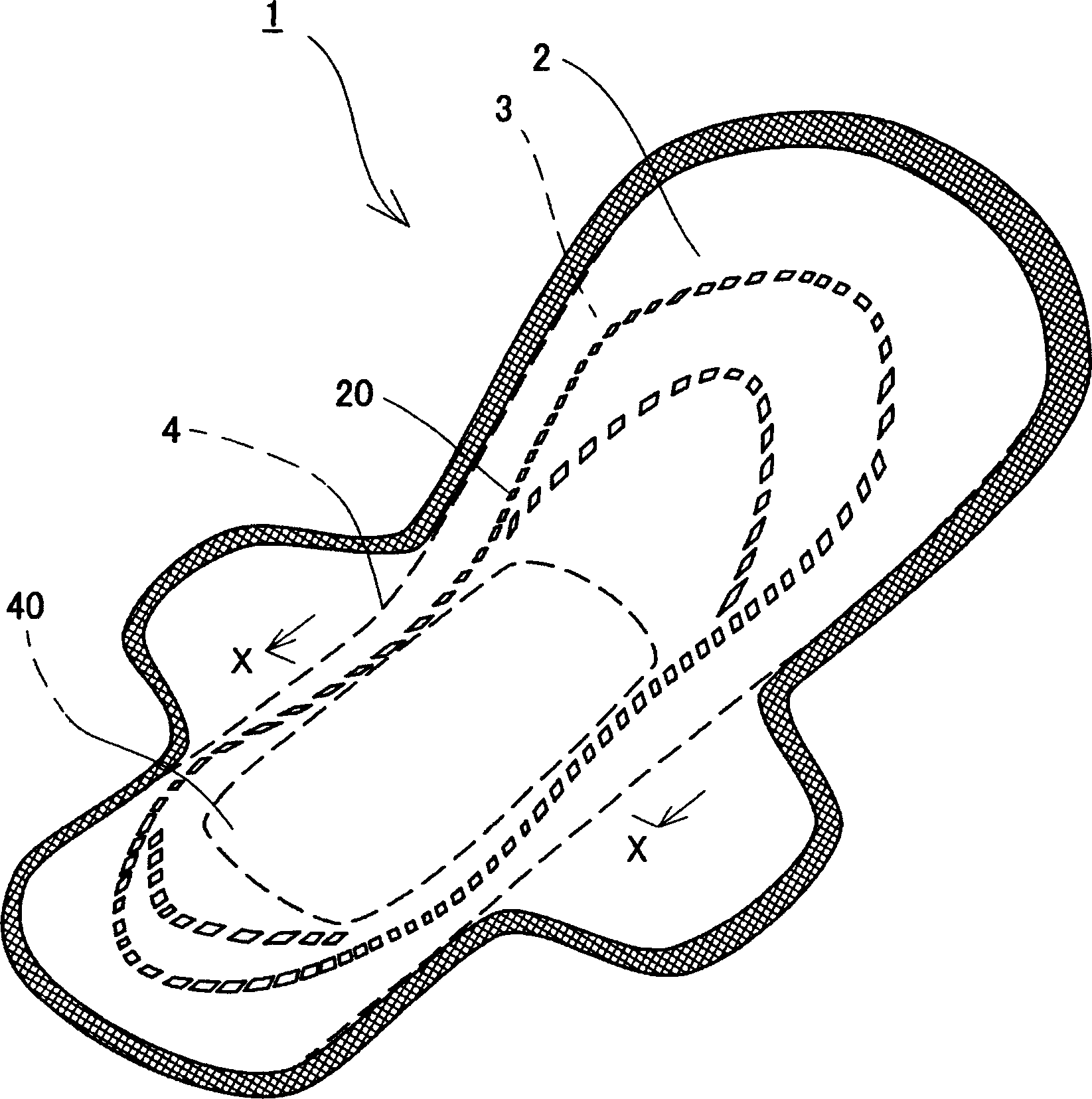

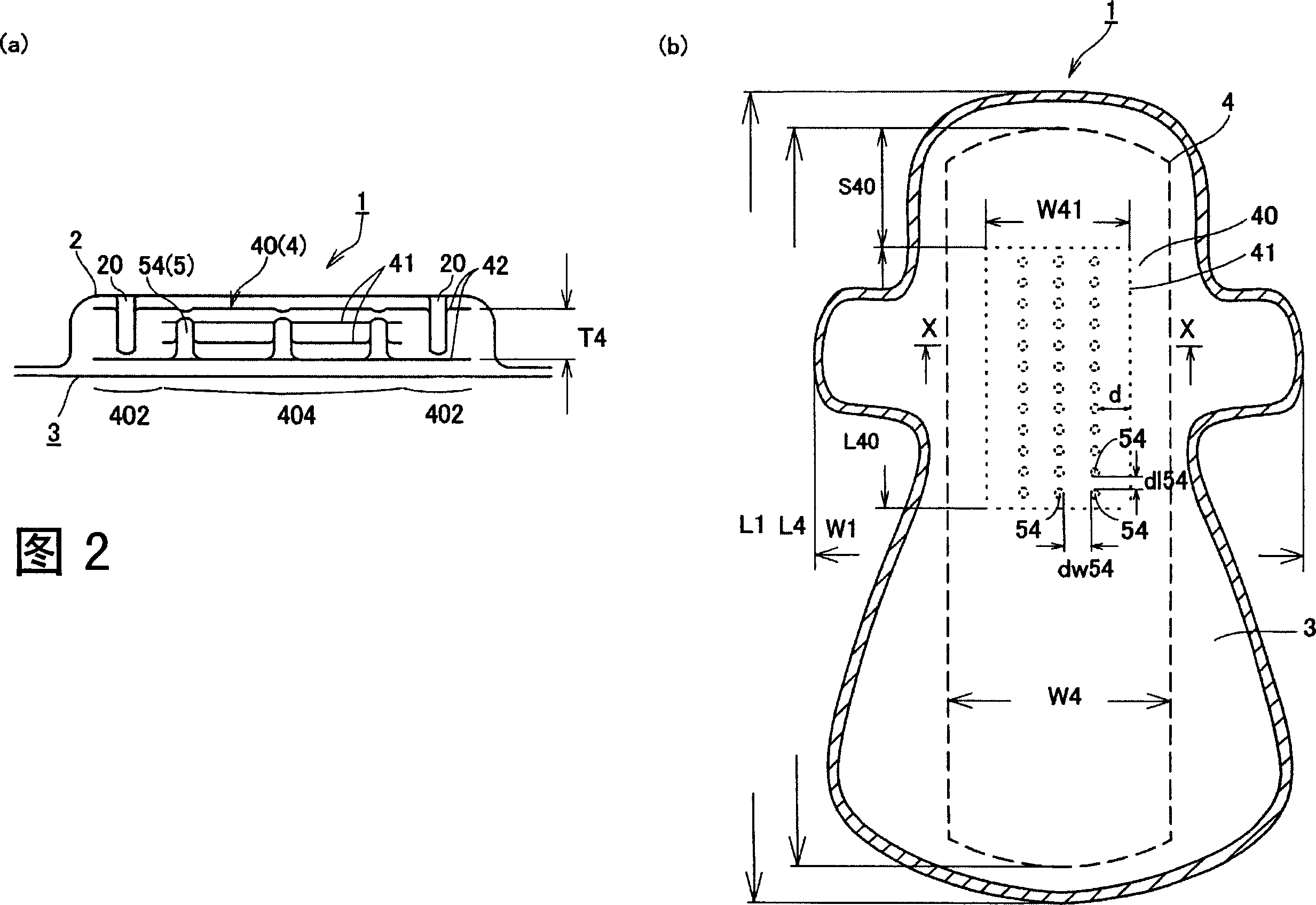

[0048] Sanitary napkins as evaluation samples were produced according to the scheme shown in Fig. 2(a) and (b). The outer shape of the sanitary napkin was set such that the overall length L1 was 300 mm, the overall width W1 of the front wing was 160 mm, and the length from the front end of the sanitary napkin to the center of the front wing was 115 mm.

[0049] Liquid-permeable sheet (front sheet): an air-through nonwoven fabric (a perforated sheet used in "Lorie s Par Slim Guard" manufactured by Kao Corporation) was used.

[0050] Liquid-impermeable sheet (back sheet): A polyethylene film with a thickness of 25 μm was used.

[0051] Absorbent sheet: As the absorbent sheet (41, 42), a sheet obtained by fixing a water-absorbent polymer in a dispersed state in the same fluff pulp fiber ("Lorie's Parslimga" manufactured by Kao Corporation) was used. ド" used in the absorbent sheet).

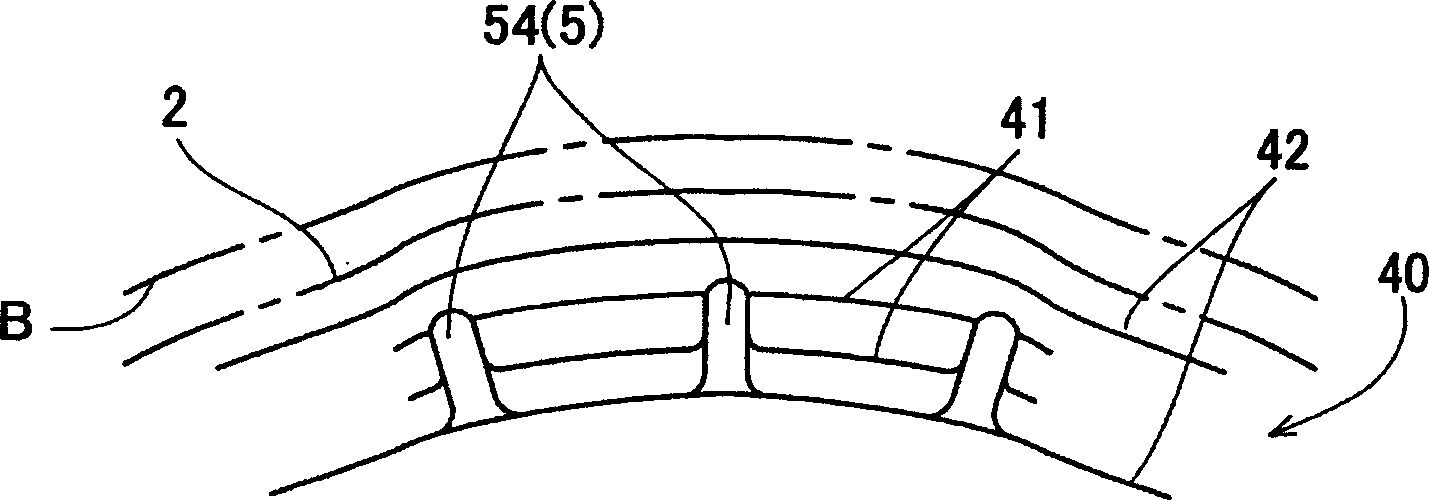

[0052] Absorbent layer: after overlapping two above-mentioned absorbent sheets (L40=90, W41=35mm...

Embodiment 2

[0057] Sanitary napkins as evaluation samples were produced according to the scheme shown in Fig. 4(a) and (b). The profile of the sanitary napkin is the same as in Example 1.

[0058] Liquid-permeable sheet (top sheet): The same nonwoven fabric as in Example 1 having a width of 70 mm was used.

[0059] Side sheet: use 18g / m 2 SMS non-woven fabric made of polypropylene.

[0060] Liquid-impermeable sheet (back sheet): The same sheet as in Example 1 was used.

[0061] Absorbent sheet: The same sheet as in Example 1 was used.

[0062] Absorbent layer: one sheet of the above-mentioned absorbent sheet is bent so that its two ends leave a gap (G41 = 2mm) and face the approximate center of the upper surface side (the liquid-permeable sheet side). After folding (L40=110, W41=40mm), further wrap the folded sheet with another above-mentioned absorbent sheet (length L4=270mm, width W4=75mm, and the front and rear ends are in a predetermined curved shape). Inside, both ends are super...

Embodiment 3

[0067] Same as Example 1, except that embossing rolls having two rows of protrusions same as in Example 1 are used to provide dimples (depth: 1.5mm, d154=6mm, dw54=13mm, d=3mm) as a stabilizing mechanism Prepare samples for evaluation. The rigidity value of the obtained absorbent layer was 1.7 cN / cm in the width direction and 1.7 cN / cm in the longitudinal direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com