Liquid jetting device

A technology of jetting device and liquid jetting head, which is applied in the direction of measuring device, sampling, printing, etc., and can solve problems such as hindering ink jetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

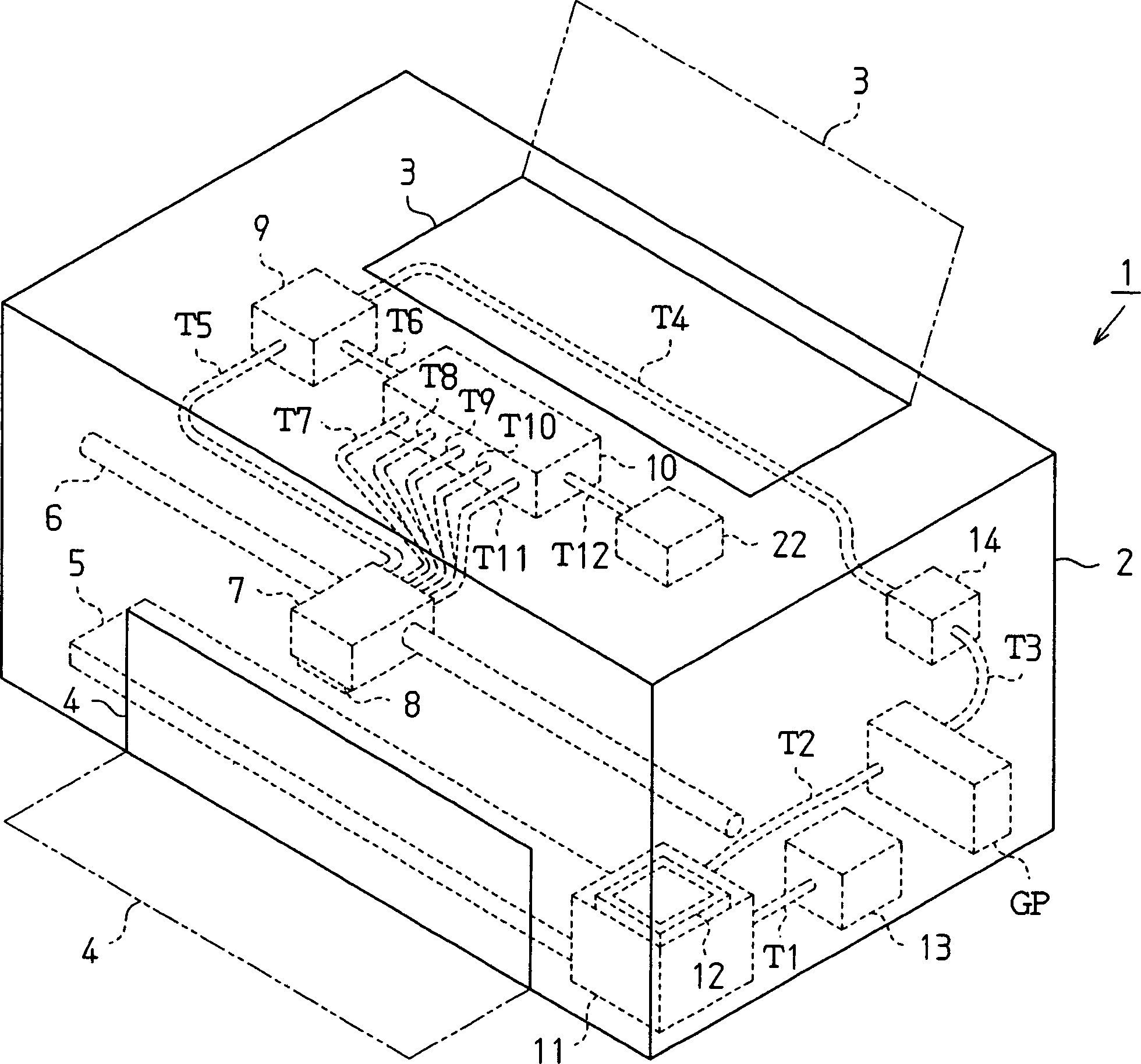

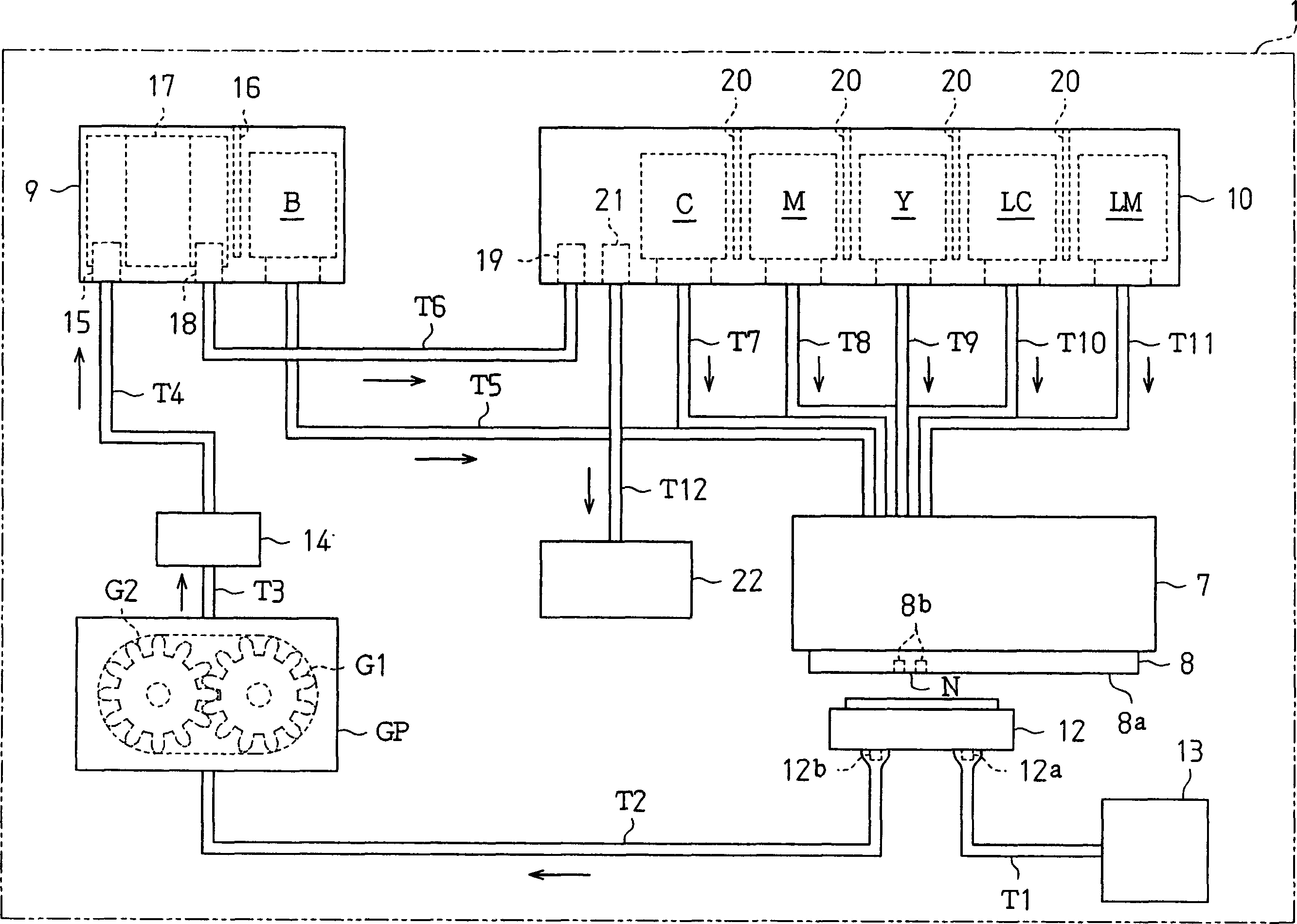

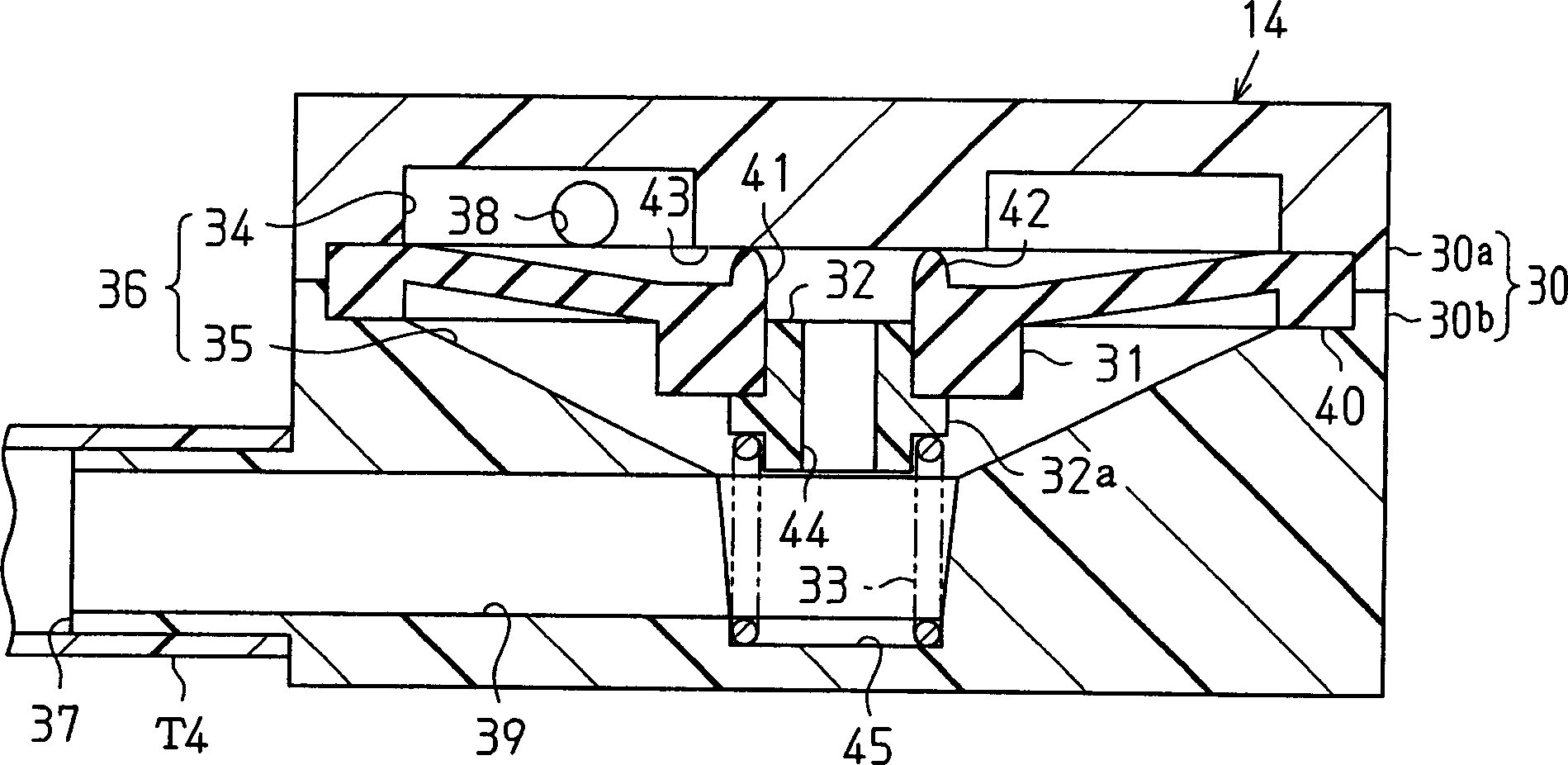

[0041] The following will refer to figure 1 A first embodiment of the present invention is described up to FIG. 4 .

[0042] Such as figure 1 As shown, a printer 1 serving as a liquid ejecting device includes a substantially parallelepiped frame 2 . A paper feed tray 3 is formed on the upper surface of the frame 2 , and a paper output tray 4 is provided on the front surface of the frame 2 . Each of the paper feed tray 3 and the paper output tray 4 is configured to be accommodated in the frame 2 in a state of being folded with an unillustrated hinge mechanism.

[0043] The deck 5 extends longitudinally in the frame 2 . Recording paper is inserted into the frame 2 via a paper feed tray 3 and supplied to a platen 5 by a paper feed mechanism not shown. Then, the recording paper is conveyed from the frame 2 to the outside via the paper output tray 4 .

[0044] A guide member 6 is provided in the frame 2 and extends parallel to the platen 5 . The carriage 7 is supported by a...

no. 2 example

[0071] The following will refer to Figure 5 and Figure 6 A second embodiment of the present invention is described.

[0072] In the second embodiment, similar to the check valve 14 of the first embodiment, the check valve suppresses the backflow of waste ink and air to the cap member 12 . The check valve of the second embodiment differs from the check valve 14 of the first embodiment in terms of the installation position relative to the frame 2 of the printer 1 . Thus, the configuration of the check valve of the second embodiment is modified accordingly. Therefore, the following description focuses on the differences between the first embodiment and the second embodiment. The same or similar reference numerals are used to designate the same or similar parts of the second embodiment as the corresponding parts of the first embodiment.

[0073] Such as Figure 5 As shown, the gear pump GP is connected to the cover member 50 through a check valve 51 and a tube T13. The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com