Rotary disk type membrane bioreactor and its water treatment method

A membrane bioreactor and bioreactor technology, applied in biological water/sewage treatment, sustainable biological treatment, chemical instruments and methods, etc., can solve problems such as insufficient water permeability, inconvenient installation and disassembly, and pollution. Achieve the effect of easy large-scale production, solve the problem of membrane fouling, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

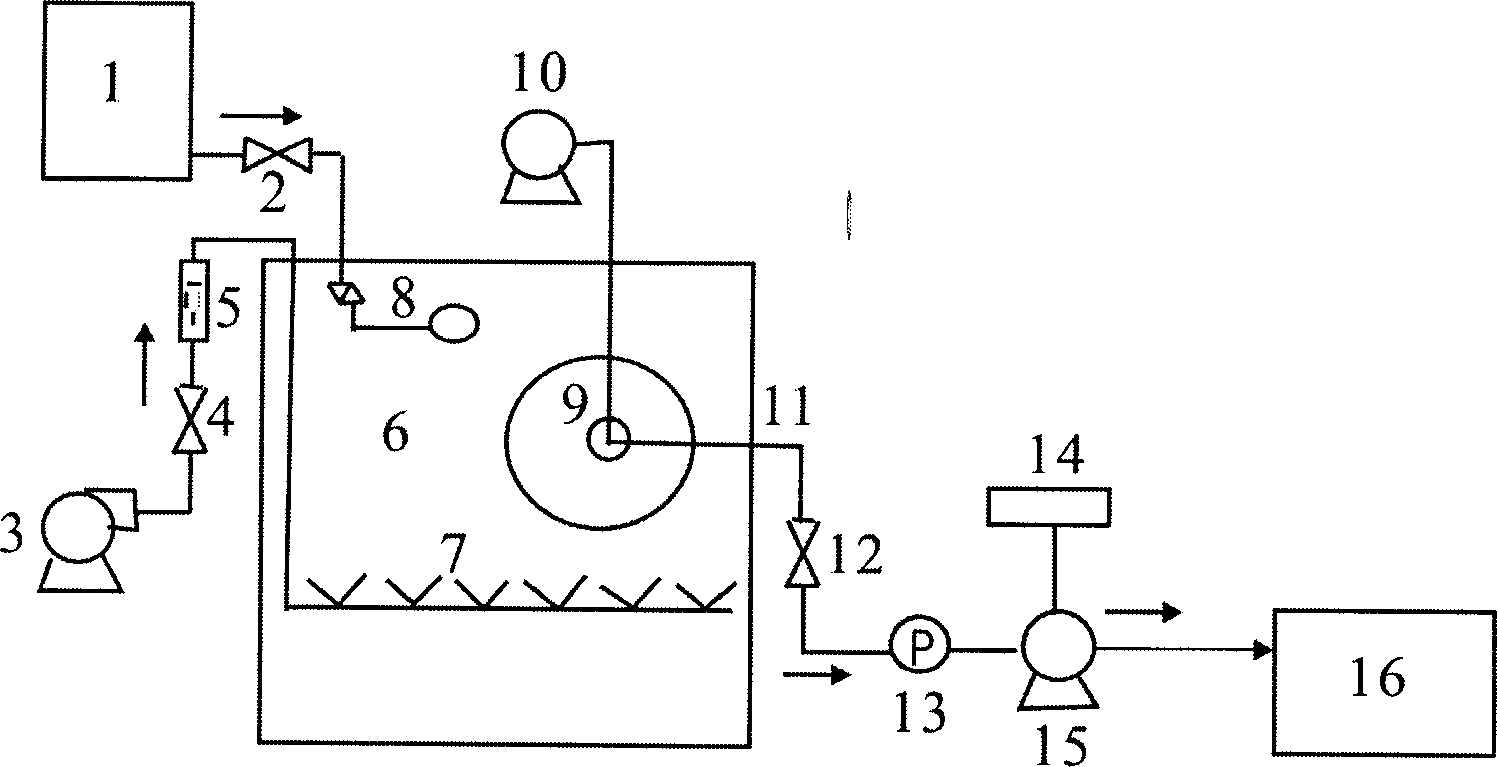

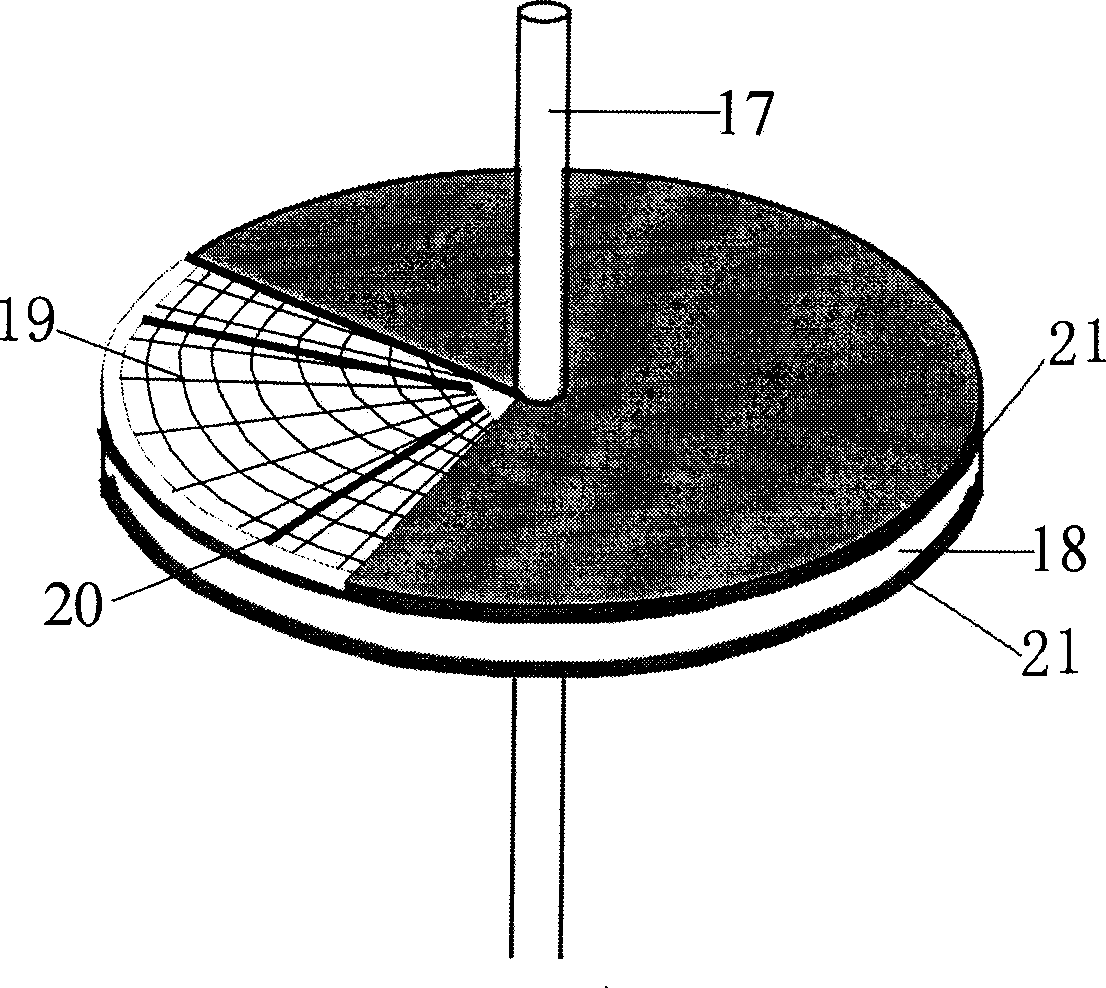

[0026] Please refer to figure 1 , figure 2 and image 3 , including raw water tank, float level valve, bioreactor, rotary membrane separator assembly, air pump, suction pump, corresponding pipes and valves. The artificial sewage is treated, and the COD value of the wastewater is 180-380mg / L. Sewage enters the bioreactor from the raw water tank, and at the same time, the air pump fills the bioreactor with air through the aeration head connected to the aeration pipe. The aeration head is located at the lower part of the membrane separator, and the aeration rate is 400L / h. The pollutants in the sewage are adsorbed by activated sludge and decomposed by microbial metabolism, and the mixed solution is intermittently accelerated and filtered out by the rotating disc membrane separator. The liquid level in the bioreactor is controlled to be constant by the float level valve. Intermittent accelerated filtration of water is realized by controlling the suction and stop of the water ...

Embodiment 2

[0028] Please refer to figure 1 , figure 2 and image 3 , using the same equipment and methods as in Example 1, except that the membrane used is changed into a microfiltration flat composite membrane. After the membrane bioreactor has been in operation for 30 days, its effluent flux is 37.5L / m 2 h, the effluent COD is less than 25mg / L, and the removal rate is greater than 90%.

Embodiment 3

[0030] Please refer to figure 1 , figure 2 and image 3 , including raw water tank, float level valve, bioreactor, rotary membrane separator assembly, air pump, suction pump, corresponding pipes and valves. The artificial sewage is treated, and the COD value of the wastewater is 180-380mg / L. Sewage enters the bioreactor from the raw water tank, and at the same time, the air pump fills the bioreactor with air through the aeration head connected to the aeration pipe. The aeration head is located at the lower part of the membrane separator, and the aeration rate is 400L / h. Pollutants are decomposed by activated sludge adsorption and microbial metabolism, and the mixed solution is intermittently accelerated and filtered out by the rotary disc membrane separator. The liquid level in the bioreactor is controlled to be constant by the float level valve. Intermittent accelerated filtration of water is realized by controlling the suction and stop of the water outlet pump through a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com