Modified device for withdrawing yarn of automatic cross-winding apparatus

An automatic device and cross-winding technology, which is applied in the field of yarn unwinding devices, can solve the problems of damaged yarn and high yarn tension, etc., and achieve the reduction of yarn unwinding tension, reduced tension, and smooth yarn The effect of unwinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

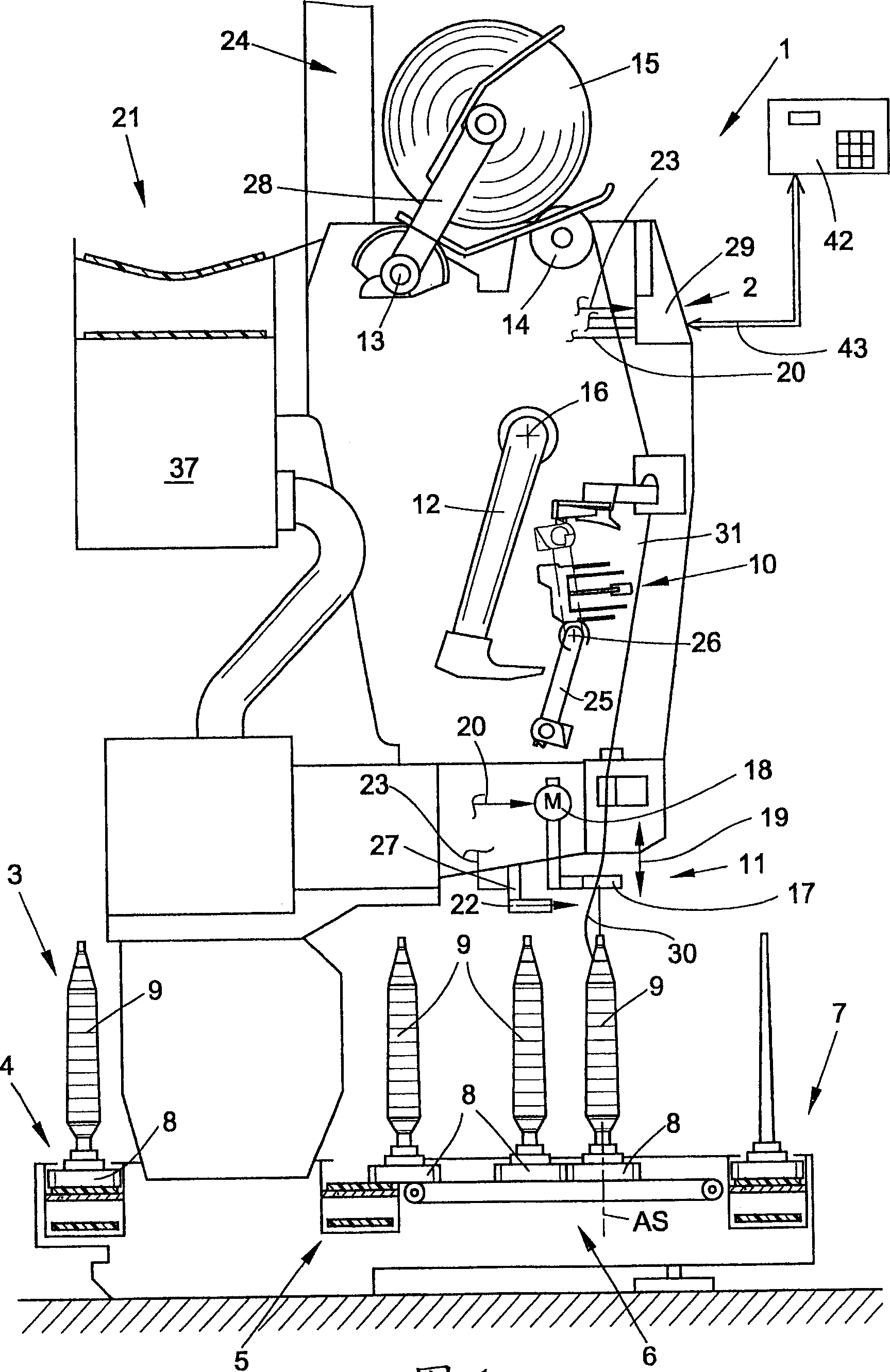

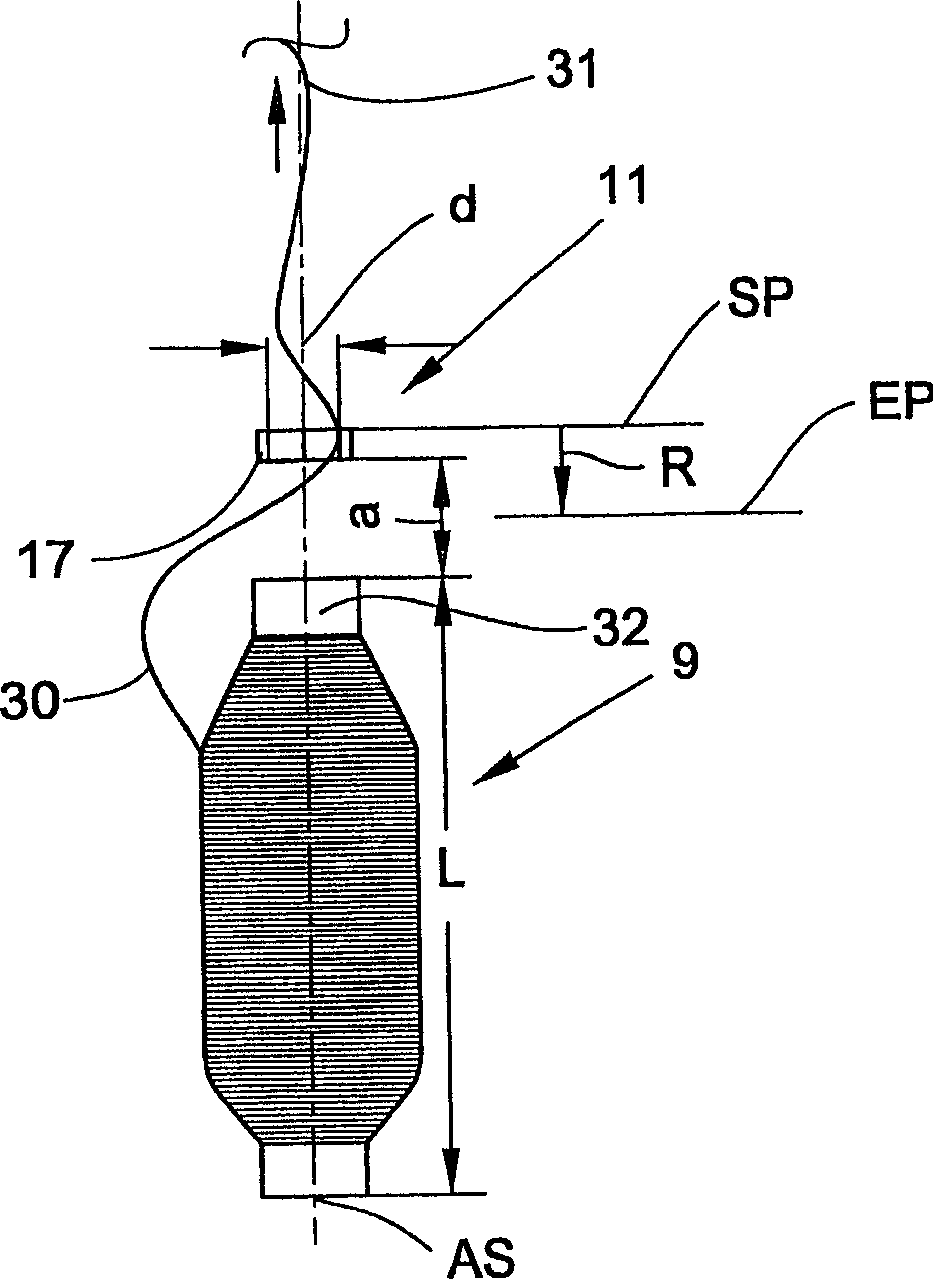

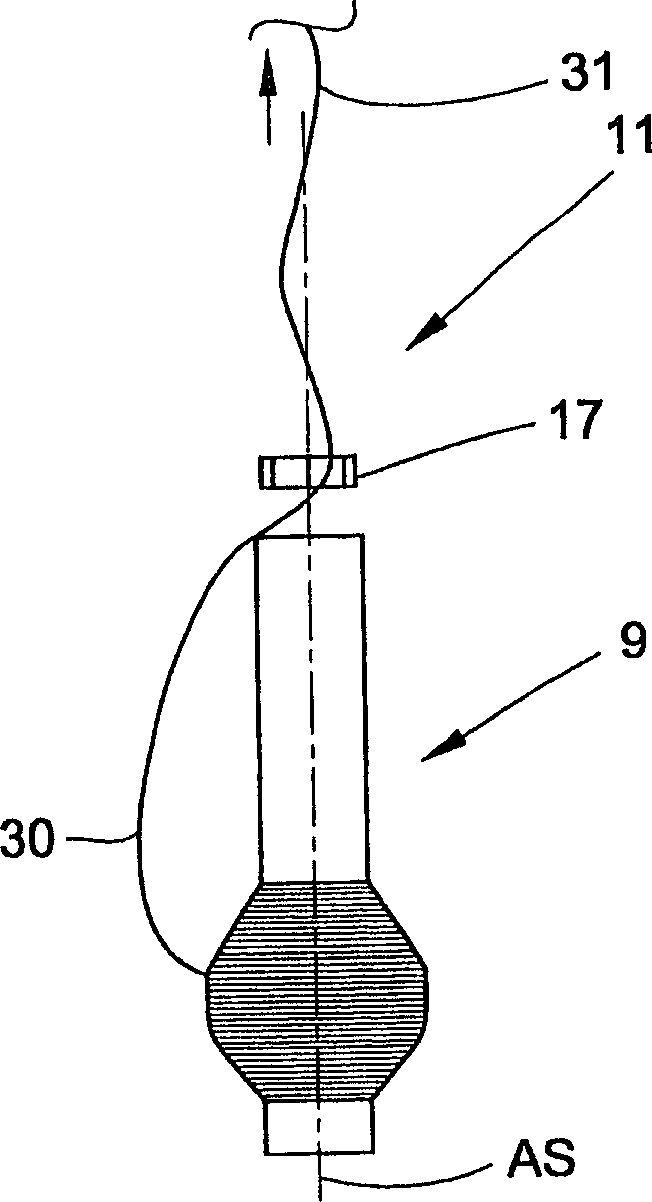

[0032] figure 1 A schematic side view of the cross-winding robot, designated as a whole by the reference numeral 1, is shown. A cross-winding robot 1 of this type usually has a plurality of identical working positions, here winding heads 2 , between its rears (not shown). As is known and therefore will not be described further, via the winding head 2, the bobbin 9 formed on the ring spinning machine is wound into large rolls of cross-wound bobbins 15, which are known according to their processing by means of automatic operating units. (Not shown) The cross-wound bobbin changeover is preferably transferred to the machine-longitudinal cross-wound bobbin conveyor 21 and conveyed to a bobbin handling station or the like arranged on the machine side.

[0033] The cross-winding robot 1 usually also has logic in the form of a winding bobbin delivery system 3 . In the winding bobbin system 3 , the bobbin 9 or the empty bobbin is wound on the delivery disc 8 . exist figure 1Only th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com