Closed loop cycle type heat sink and screen module using the same

A heat dissipation device and closed-loop technology, applied in the field of screen modules, can solve the problems of lowering the temperature, effectively reducing the heat, and unable to reduce the temperature, and achieve the effects of reducing the difficulty of manufacturing and assembling, increasing the heat dissipation capacity, and reducing restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

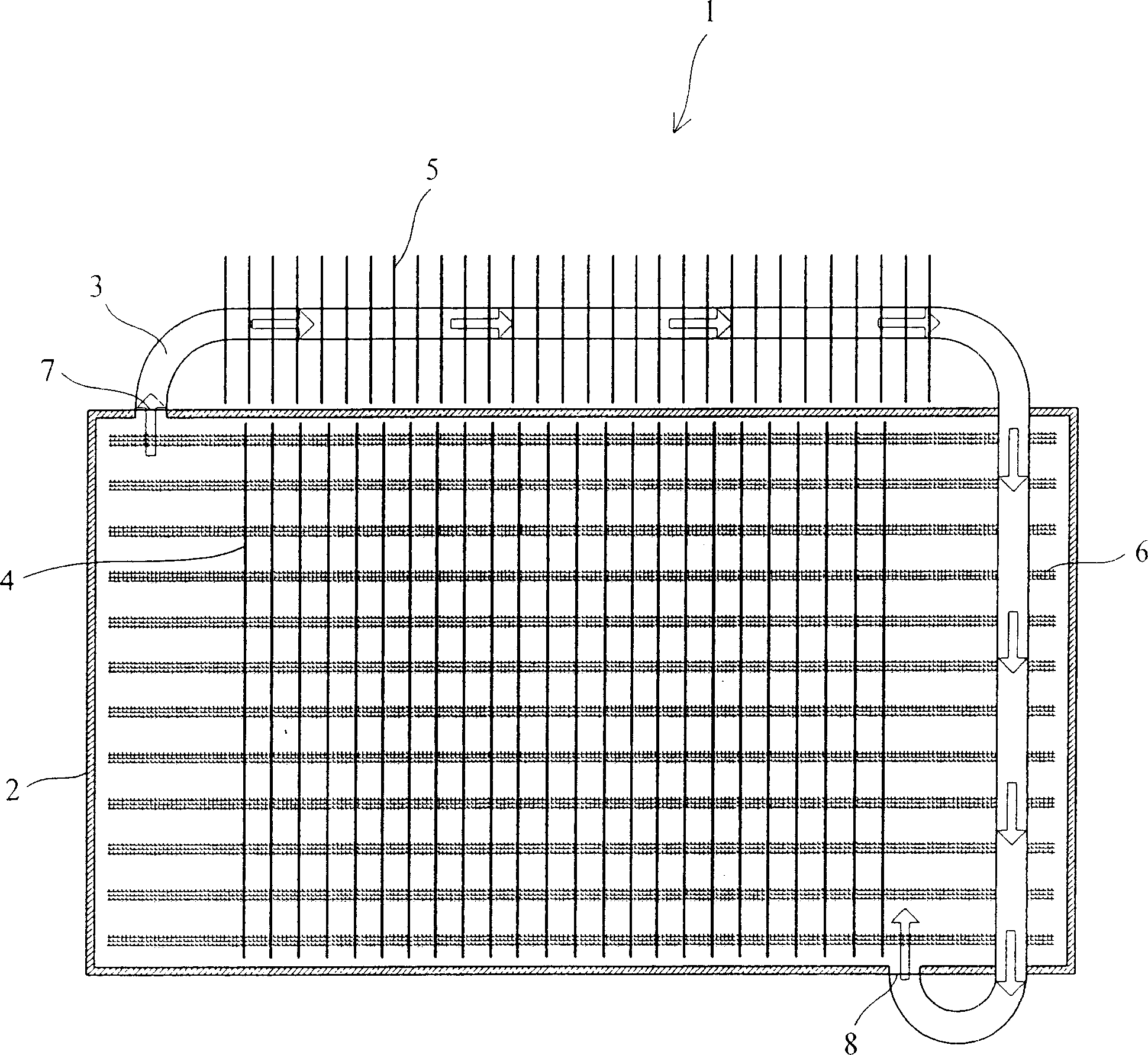

[0022] refer to figure 1 Shown is a schematic structural diagram of the screen module 1 of the present invention. According to a preferred embodiment of the present invention, one end of a metal conduit 3 communicates with the upper outlet 7 of the casing 2, goes around one side of the casing 2, and finally the other end of the metal conduit 3 communicates with the top outlet 7 of the casing 2. The lower entrance 8; a plurality of heat dissipation fins 4 are arranged at the rear of the housing 2; and a plurality of heat dissipation fins 5 are attached to the metal conduit 3 along the diameter direction of the metal conduit 3 and arranged in parallel at certain intervals; the casing 2 contains a light-emitting and heat-emitting lamp module 6 or a screen module, wherein the screen module can be a flat display screen of a liquid crystal screen module, a plasma screen or a computer screen.

[0023] The heat generated by the casing 2, on the one hand, dissipates heat through a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com