Method for determining treatment of pie body based on bearing capacity of single pile when rejecting hammer in subsequent piling

A technology of bearing capacity and single pile, which is applied in the direction of sheet pile wall, foundation structure engineering, water conservancy engineering, etc., can solve the problems of hammer rejection, avoid construction delays and economic losses, obtain simple and easy methods, and high analysis efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

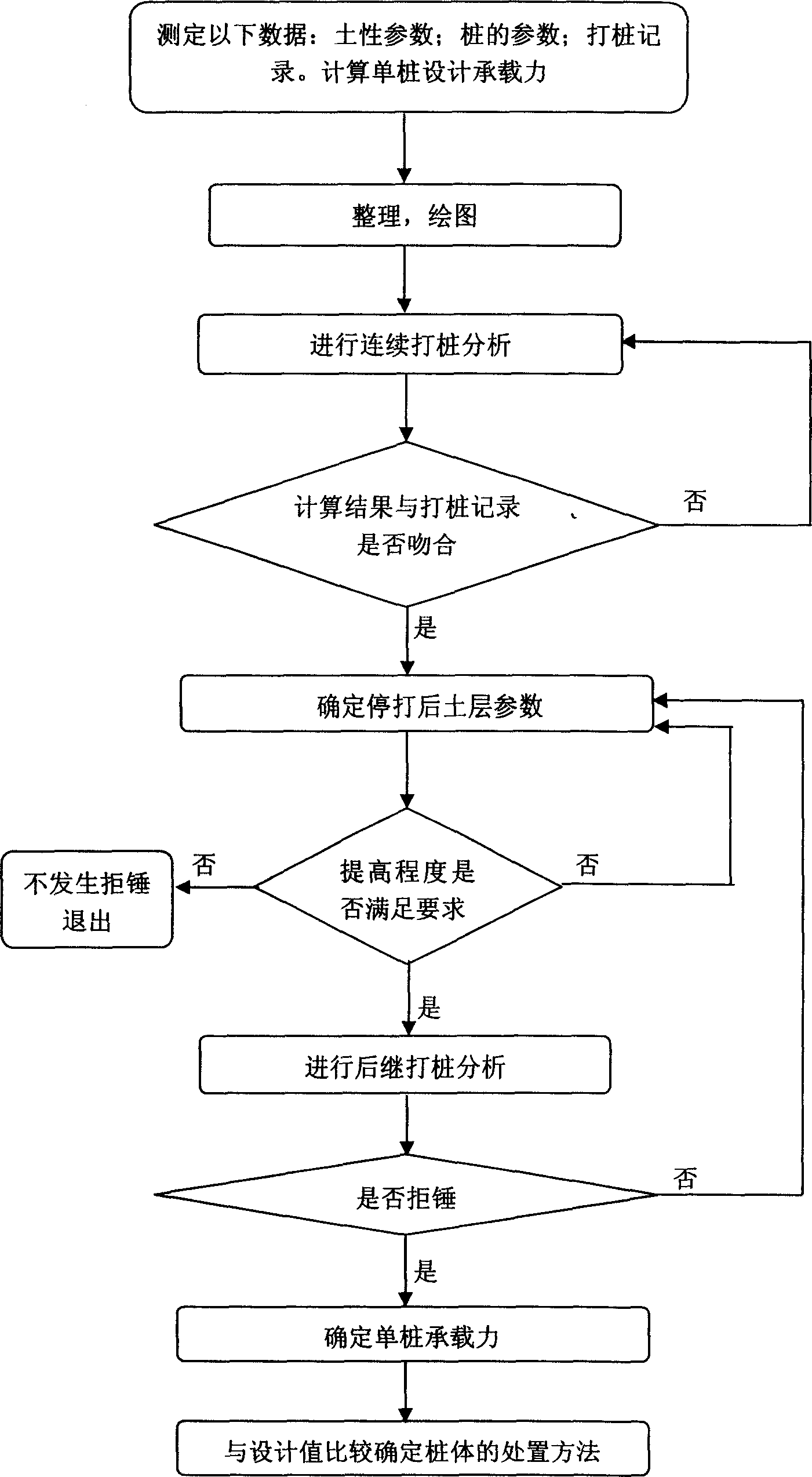

Method used

Image

Examples

Embodiment Construction

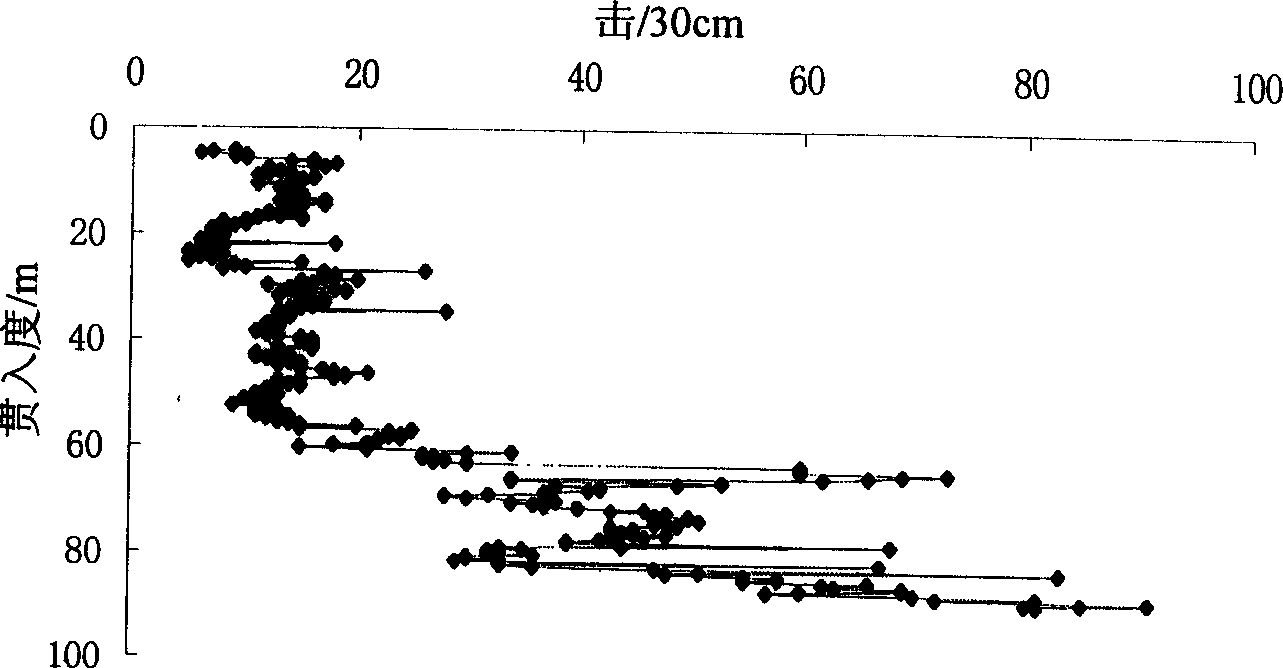

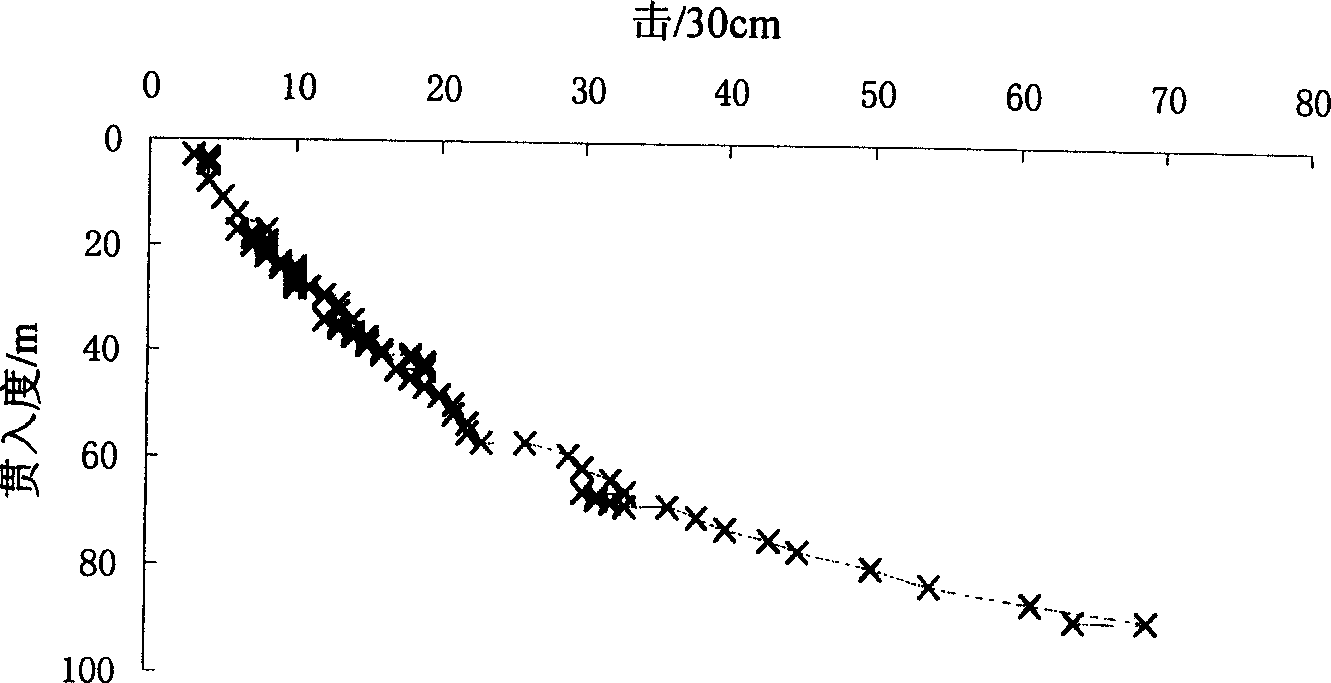

[0050] A project is located in the Bohai Sea of my country, using steel pipe piles with a diameter of 1.524m, and the design penetration depth is 104m. During the driving process, the driving was stopped for 15 days when the soil depth reached about 88.7m, and the phenomenon of hammer rejection occurred during the subsequent piling. The engineering information is as follows:

[0051] layer

name

Soil description

the depth

efficient

severe

(kN / m 3 )

Design Shear Strength

(kPa)

unit surface

friction

unit pile end

layer top

(m)

layer bottom

(m)

(kPa)

(MPa)

1

very soft to soft silty clay

0.0

7.8

4

0

0.04

2.0

9.0

7.5

6

0.07

2.0

9.4

16

8

0.14

3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com