Method and device for laser marking based on liquid crystal mask tech.

A laser marking method and mask technology, applied in the field of laser marking based on liquid crystal mask technology, can solve the problems of difficult mask making, high cost, blurred graphic marks, etc., to avoid blurred marks and long service life , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

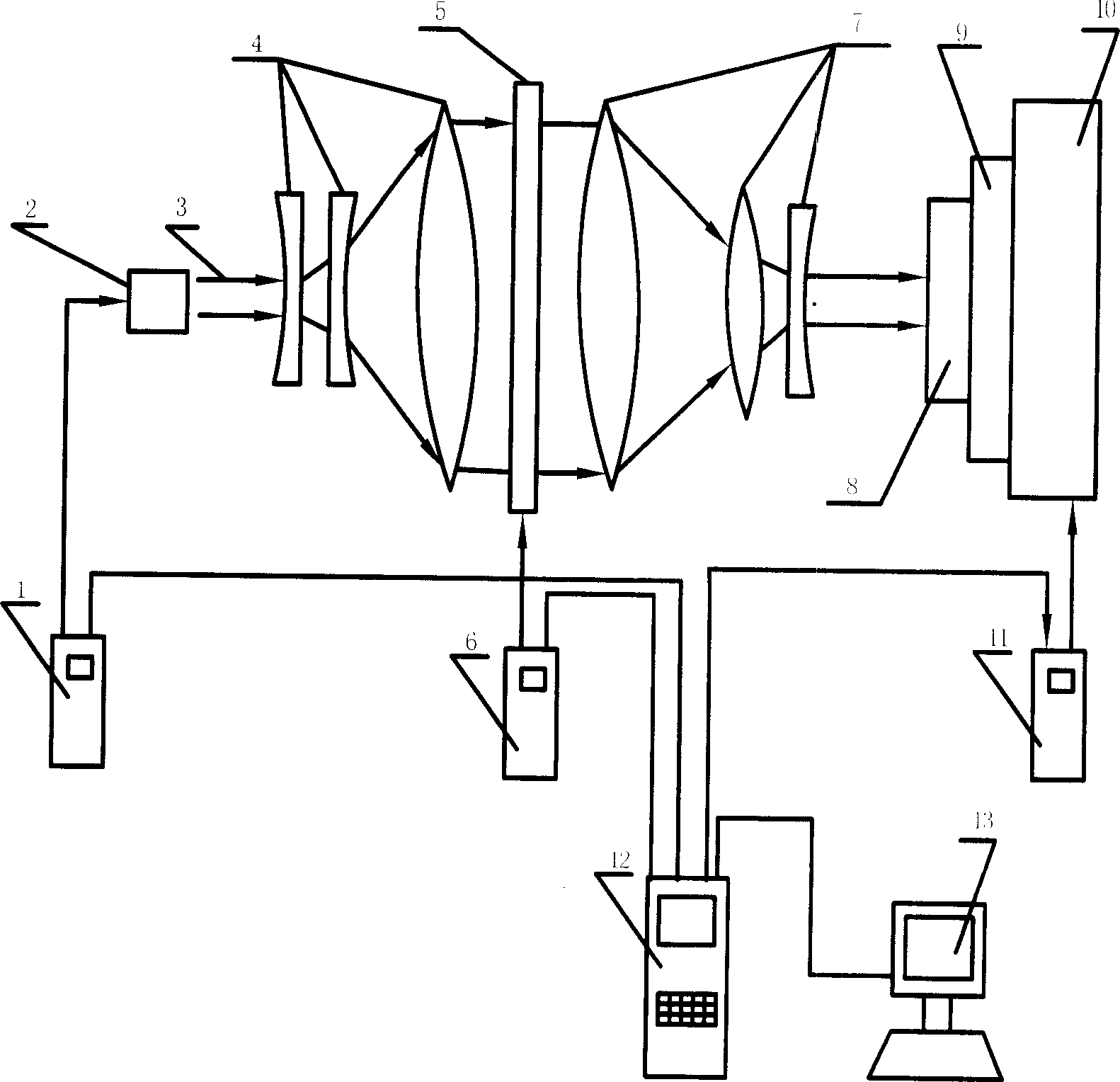

[0018] Combine below figure 1 Describe in detail the details and working conditions of the specific device proposed by the present invention.

[0019] The device for carrying out laser marking with the method of the present invention comprises a laser generator control device 1, a laser generator 2, an astigmatism system 4, a liquid crystal display screen 5 and a display screen control device 6, a focusing system 7 and a workpiece fixture system, and laser generators A digital control system 12 and a computer 13 connected to the device control device 1 , the display screen control device 6 , and the workbench control device 11 . Among them, the astigmatism system 4 is composed of a group of concave lenses and a convex lens with a large curvature; the focusing system 7 is composed of a group of convex lenses and a concave lens with a large curvature; the workpiece fixture system includes a workpiece 8, a fixture 9, a workbench 10 and a workbench control device 11 .

[0020] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com