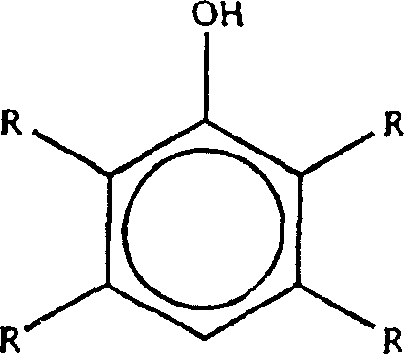

Bromination of hydroxyaromatic compounds and further conversion to dihydroxyaromatic compounds

A hydroxyaromatic and brominated hydroxyaromatic technology is applied in the conversion of monocyclic dihydroxyaromatic compounds and dihydroxybiphenyls, compounds to brominated derivatives, the preparation of brominated hydroxyaromatic compounds, and the field of polyetherimide. Solve problems such as bromophenol not being promoted, and achieve easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

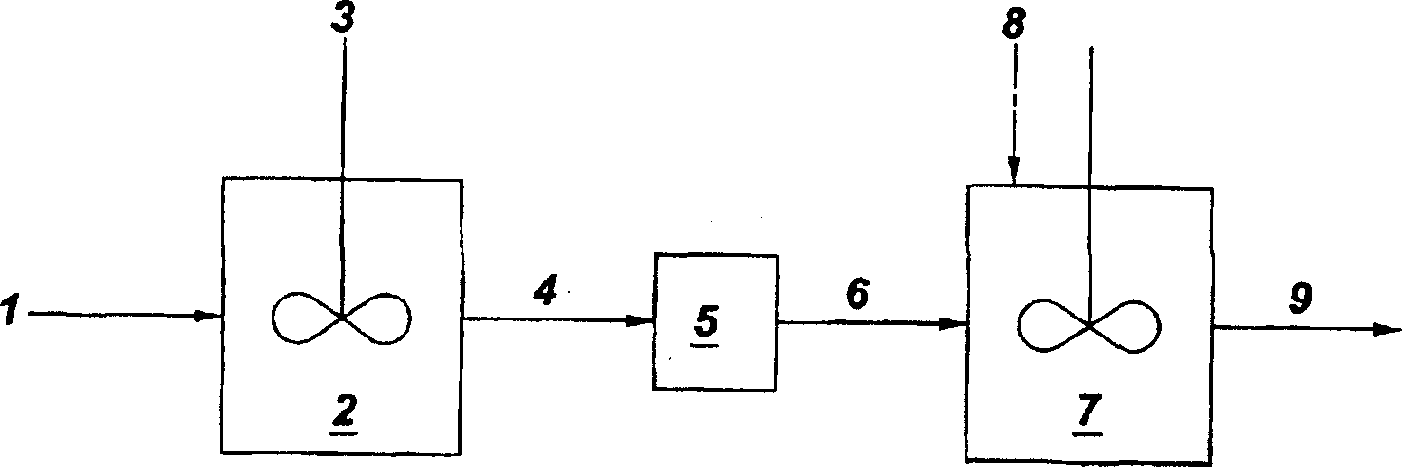

Method used

Image

Examples

Embodiment 1

[0039] A 3-dram vial was charged with 1.37ml (15.56mmol) phenol, 0.112g (0.5mmol) copper bromide, 1.39ml (12.50mmol) 48% hydrobromic acid and 2.20ml acetonitrile. The vial was sealed with a cap with a hole for air flow during the reaction and placed in an aluminum block. The aluminum block was placed in a 450 ml autoclave reactor, pressurized with air to 34.0 atmospheres and heated at 65°C for 1 hour. It was then cooled to room temperature and the pressure reduced. Analysis of the obtained mixture by gas chromatography showed it to contain 7.39% phenol, 28.63% 4-bromophenol, 5.59% 2-bromophenol and 0.68% 2,4-dibromophenol, corresponding to 72% conversion of phenol, There is 82% selectivity to 4-bromophenol and 98% selectivity to total monobromophenol.

Embodiment 2

[0041] A 3-dram vial was charged with 1.59 ml (15.39 mmol) o-cresol, 0.112 g (0.5 mmol) copper bromide, 1.48 ml (12.47 mmol) 48% hydrobromic acid and 1.92 ml acetonitrile. As in Example 1, the vial was sealed and placed, pressurized with air to 34.0 atmospheres and heated at 65°C for 1 hour. It was then cooled to room temperature and the pressure reduced. Analysis of the obtained mixture by gas chromatography showed that it contained 13.23% o-cresol, 27.74% 4-bromo-2-cresol and 0.93% 6-bromo-2-cresol, corresponding to 56% o-cresol - Cresol conversion with 96% selectivity to 4-bromo-2-cresol and 99% selectivity to total monobromophenols.

Embodiment 3

[0043] A 3-dram vial was charged with 1.37 ml (15.56 mmol) of phenol, 0.112 g (0.5 mmol) of copper bromide, 1.30 ml (6.85 mmol) of 30% hydrogen bromide in acetic acid and 2.31 ml of acetonitrile. As in Example 1, the vial was sealed and placed, pressurized with air to 34.0 atmospheres and heated at 65°C for 1 hour. It was then cooled to room temperature and the pressure reduced. Analysis of the obtained mixture by gas chromatography showed that it contained 14.12% phenol, 19.15% 4-bromophenol and 1.15% 2-bromophenol, corresponding to 44% conversion of phenol, 96% selectivity to 4-bromophenol and 100% total monobromophenol selectivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com