In-situ synthetic method for WC-Co hard alloy

A cemented carbide and in-situ synthesis technology, applied in the field of reaction sintering, to achieve the effects of reducing cost and energy consumption, purifying the surface of particles, and being easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

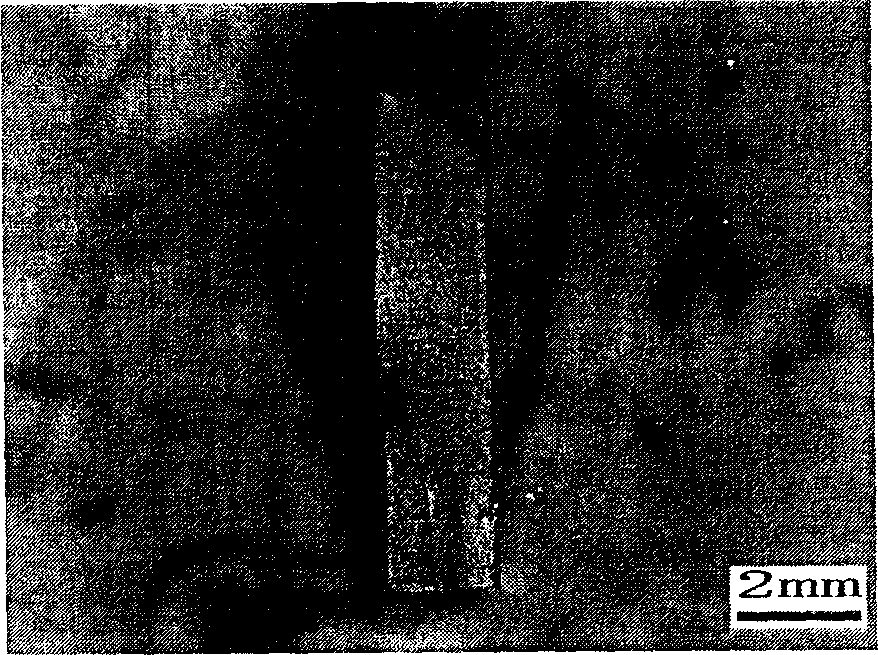

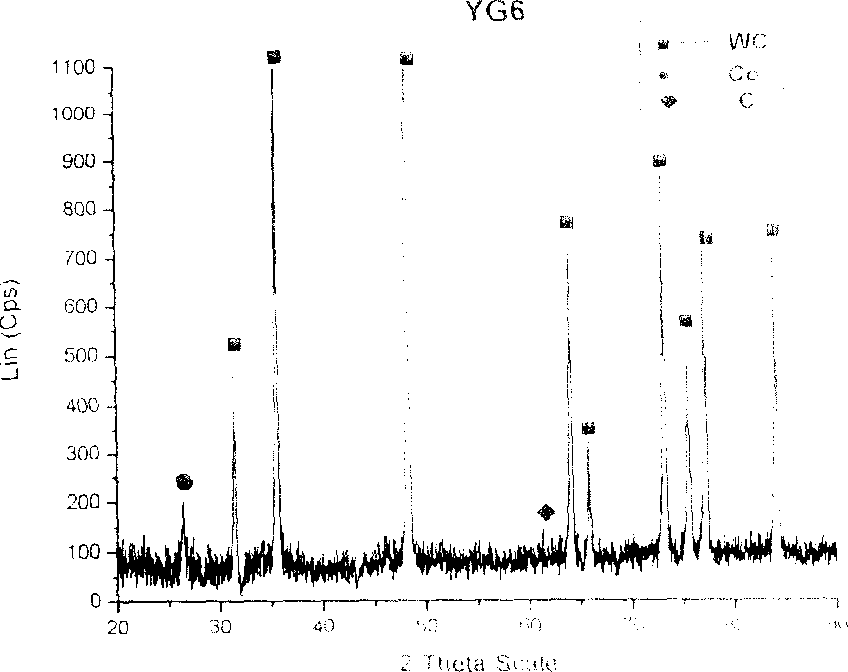

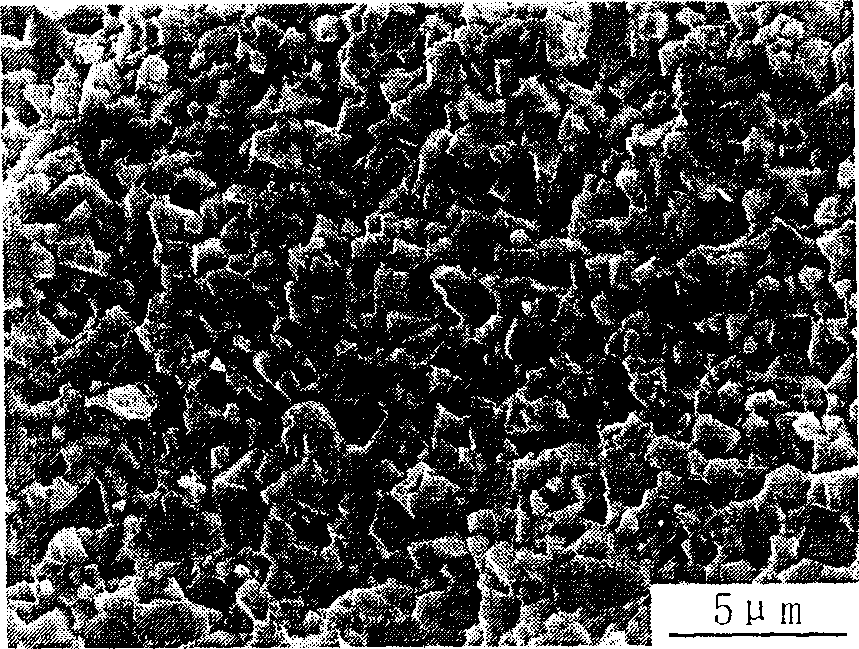

[0013] 1. 78.0% by weight of WO 3 With 13.0% by weight carbon black and 8.0% by weight Co 3 o 4 Add absolute ethanol to the powder, put it into a high-energy ball mill for powder mixing and ball milling for 20 hours, bake at 120°C for 1 hour, pass through a -120 mesh sieve, put the mixed powder into a φ20 graphite mold, and press it tightly. Then put it into SPS for sintering, evacuate to 3~4Pa, add 10MPa pressure in advance, and heat up rapidly at 100°C / min. to 30MPa, after the vacuum degree returns to 3-4Pa, the temperature is raised at 70°C / min to 1200°C for 2 minutes, then cooled slowly to room temperature and taken out to obtain WC-Co cemented carbide material. The sintered body is not delaminated ( figure 1 ), XRD analysis showed WC and Co phases ( figure 2 ).

[0014] 2. 80.0% by weight of WO 3 With 15.0% by weight carbon black and 5.0% by weight Co 3 o 4 Add absolute ethanol to the powder, put it into a high-energy ball mill for powder mixing and ball milling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com