Hetero-polycyclic compounds, and coloring matters, pigments, dyes, color-changing material compositions, and color-changing films, made by using the compounds

A color-changing material and heteropolycyclic technology, applied in the direction of azo dyes, organic dyes, luminescent materials, etc., can solve the problems of poor color-changing performance and unusable films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0388] (A) fluorescent dye, (B) binder material, (C) binder resin, (D) monomer having a photopolymerizable ethylenically unsaturated group and / or Oligomers, (E) compounds having epoxy groups, and other components (including solvents) are used to prepare the color-changing material composition.

[0389] Example 1

Example 2

Example 3

Fluorescent pigment

(A component)

Compound 1

0.072g

Compound (V-a)

0.034g

Compound (V-a)

0.034g

Rhodamine 6G

0.017g

0.017g

binder resin

(C component)

Benzyl methacrylate-methacrylic acid copolymer

(Mw=27,000, q=0.80)

1.9g

Methyl methacrylate-methacrylic acid copolymer

(Mw=25,000, q=0.85)

1.9g

Same as Example 2

monomer /

(D component)

Dipentaerythritol hexaacrylate

(Aronix M-400, produced by Toa Gosei)

1.5g

trimethylolpropane triacrylate ...

Embodiment 4-13

[0400] (A) fluorescent dye, (B) binder material, (C) binder resin, (D) monomer having a photopolymerizable ethylenically unsaturated group and / or Oligomers, (E) compounds having epoxy groups and other components (including solvents) are used to prepare the color-changing material composition.

[0401] Example 4

[0402] Example

[0403] Example 9

[0404] Example

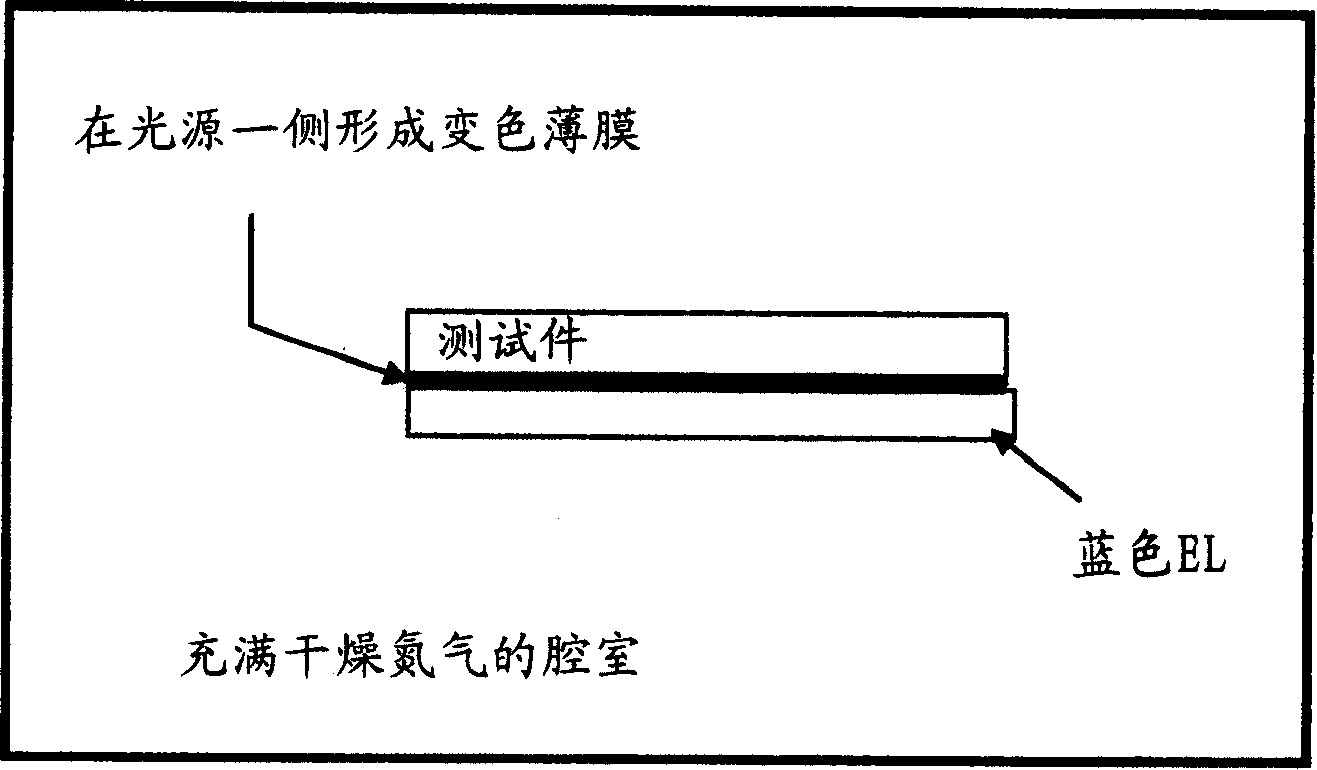

[0405] Using the color-changing material composition obtained in Examples 4-13, a thin film was prepared on a 2.5 cm×5 cm glass substrate by spin coating. The film was produced at a spin-coating speed of 1000 rpm and a spin time of 10 seconds, and was dried at 120° C. for 2 minutes.

[0406] Afterwards, the films produced in Examples 4-11 were treated with 300mJ / cm 2 UV ray irradiation, and then heat treatment at 200 ° C for 60 minutes to obtain a color-changing film with a thickness of 10 μm or less. The film prepared in Example 12 was only heat-treated at 200°C for 60 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com