Air-cooled diesel engine

A diesel engine, air-cooled technology, applied in air cooling, mechanical equipment, engine components, etc., can solve the problems of poor stiffness and stability, overall bulky, complex manufacturing process, etc., to reduce mechanical noise and vibration, the overall structure is compact, and the overall Lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

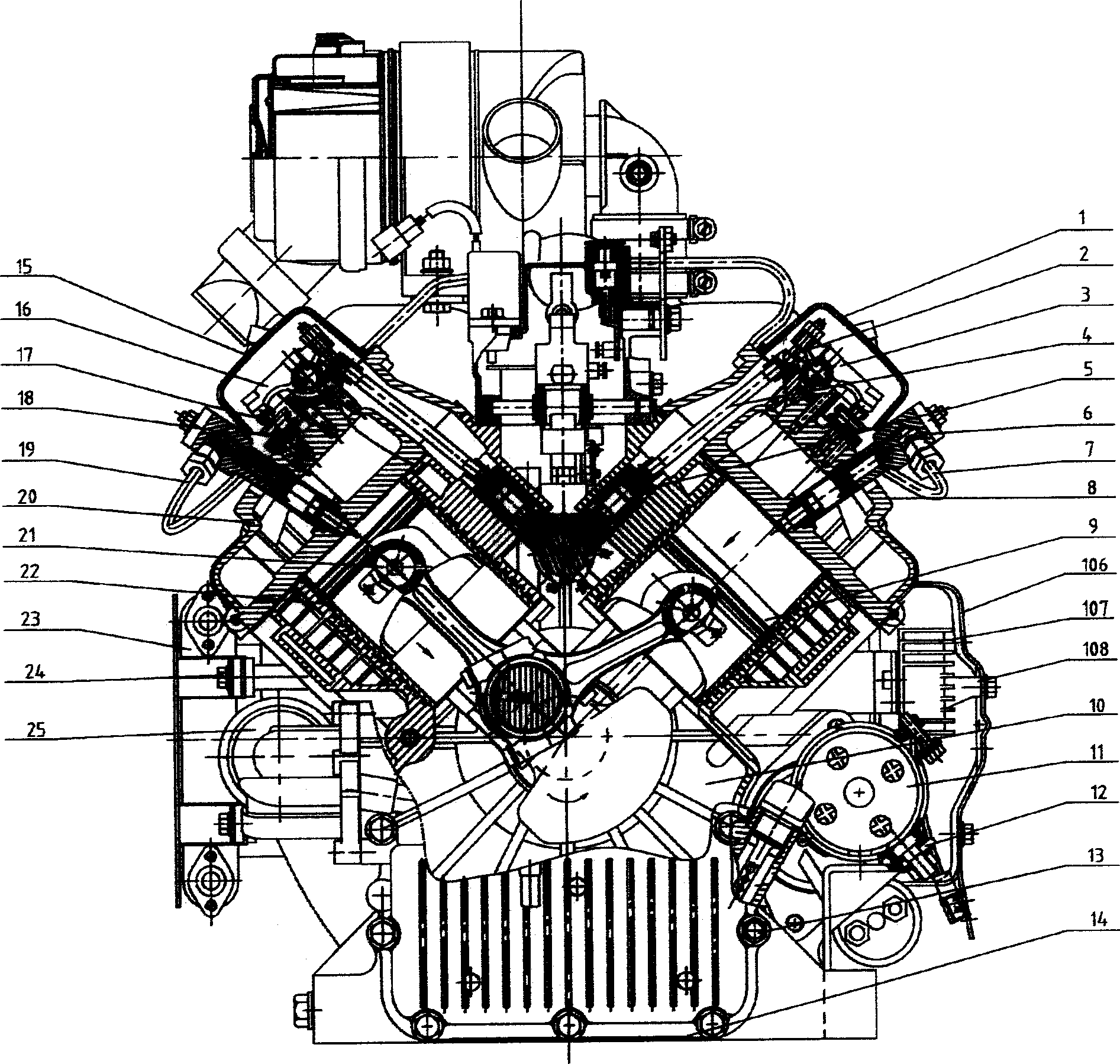

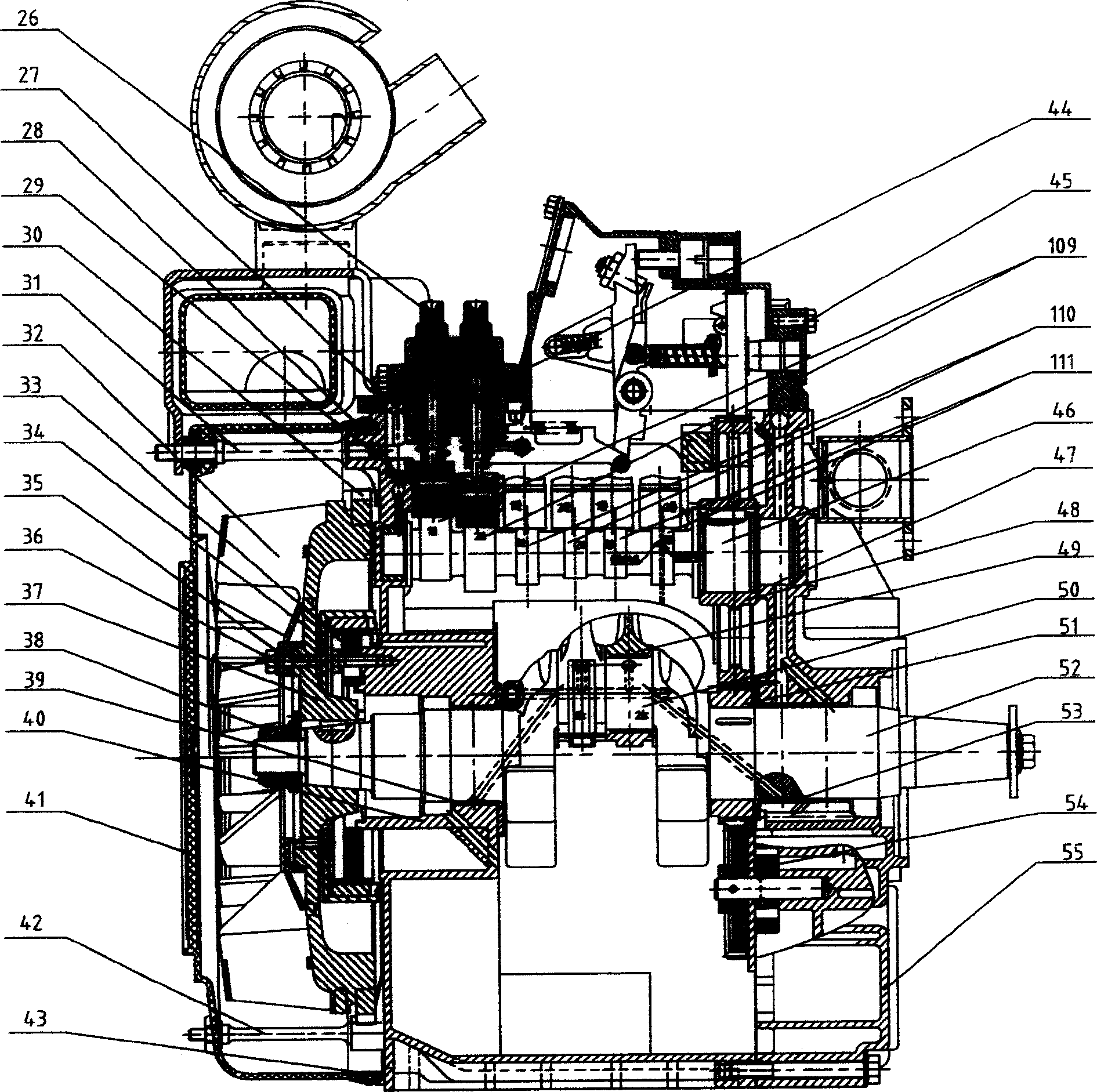

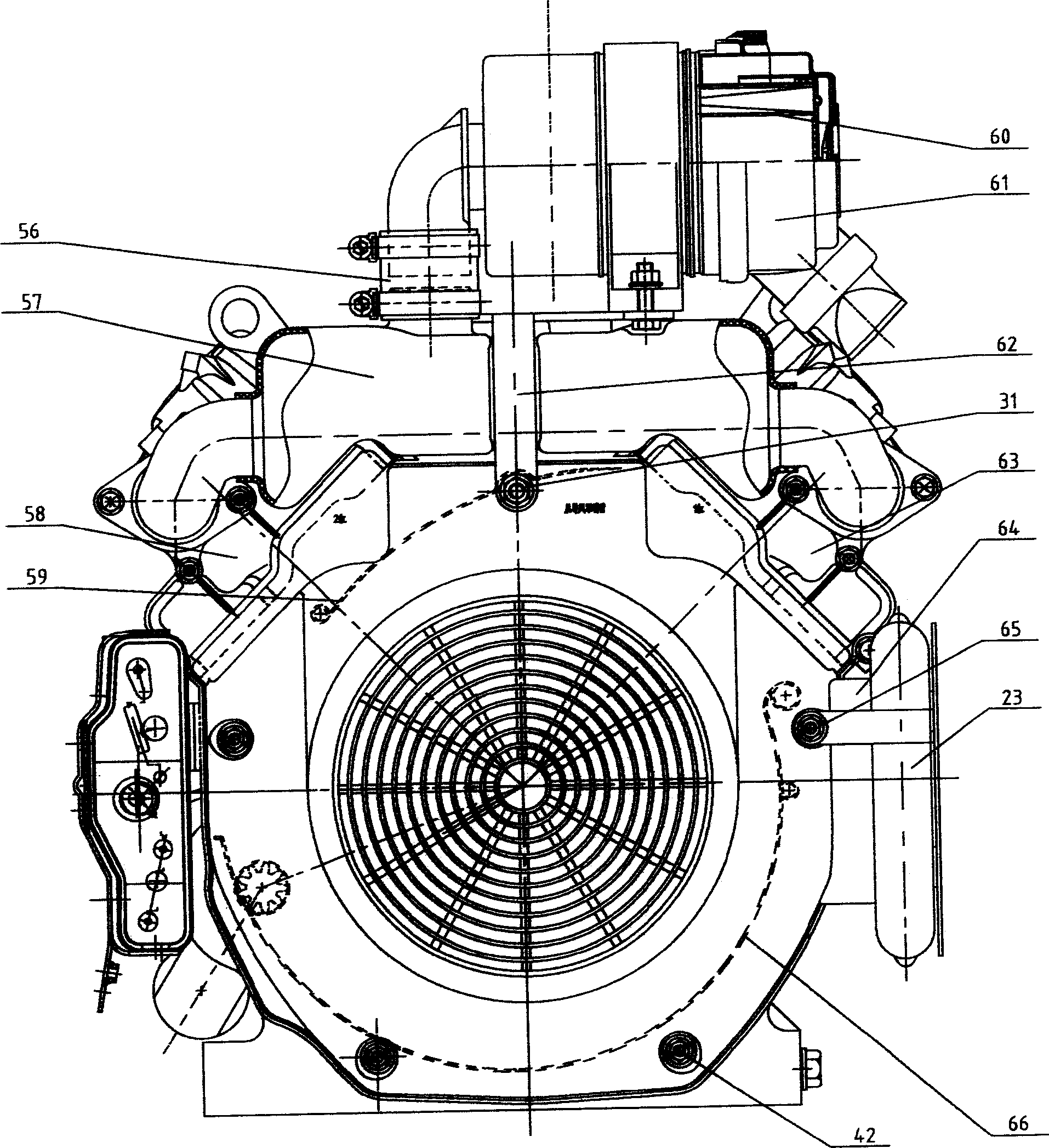

[0035] In the embodiment of the present invention (see figure 1 , 2 ) for a detailed description of its assembly relationship and functions. Adopt body 40 left and right cylinders 68,76 to become V-shaped 90 ° arrangement, crankcase cover 55 is fixed on the joint surface 80 of body 40 and crankcase cover 55 with multiple bolts 13 (see figure 1 ), a sealed space (crankcase) 10 is formed between the body 40 and the crankcase cover 55, and the crankshaft 52 is housed in this sealed space. The crankshaft 52 has two main journals and a connecting rod journal 50, and the crankshaft 52 main shaft One end of the neck is supported in the main bearing hole 39 of the body 40 (see figure 2 ), the other end is supported in the main bearing hole 53 of the crankcase cover 55 (see figure 2 ), two connecting rods 49 are housed on crankshaft 52 connecting rod jou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com