Machining method for irregular key axis blank

A processing method and special-shaped key technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of high processing cost and high rejection rate, and achieve the effect of reducing processing cost, improving internal organization, and shortening process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

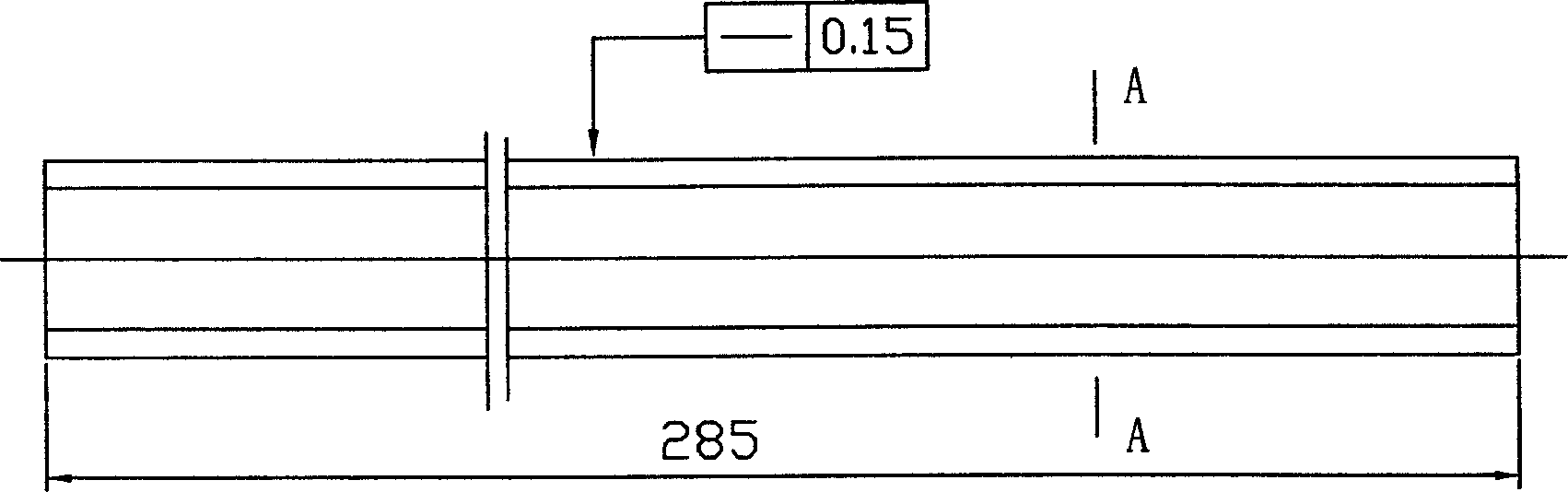

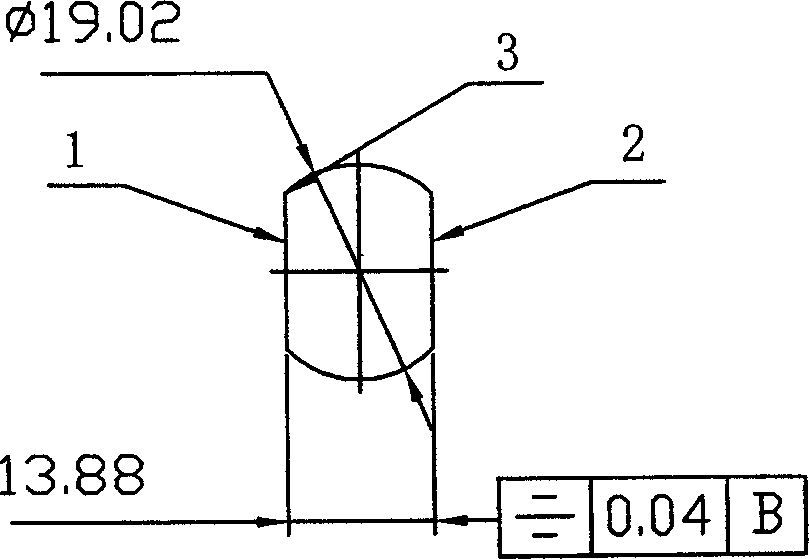

[0013] combine figure 1 , figure 2 The special-shaped key shaft blank of the steering machine shown in the description of the embodiment of the present invention is as follows:

[0014] The special-shaped key shaft blank of the steering machine uses No. 35 cold-drawn round steel with a diameter of 22 mm as the raw material, and is realized through the following steps:

[0015] a. After annealing, pickling and phosphating the cold-drawn round steel, then sharpen it, and cold-draw the outer circular surface and double-sided flat parts through the forming die in the wire drawing machine to obtain the initial flat blank. The diameter of the outer circular surface is 22 mm to 19.9 mm, the thickness of the flat part on both sides is 18 mm to 17.9 mm;

[0016] b. Then the initial flat blank is annealed, pickled, phosphated, then sharpened, and the outer circular surface and double-sided flat parts are formed by cold drawing again through the forming die on the wire drawing machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com