Combined wind energy and hydraulic power varying generator

A power generation equipment and variable power technology, which is applied in wind power generation, mechanical equipment, wind engines, etc., can solve the problems of increased manufacturing costs, difficulties in transportation, erection, monitoring, and maintenance, restrictions on the development and utilization of green and environmentally friendly wind energy, manufacturing costs and Problems such as high equipment installation cost, etc., to achieve the effect of easy erection and maintenance, material saving, and manufacturing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

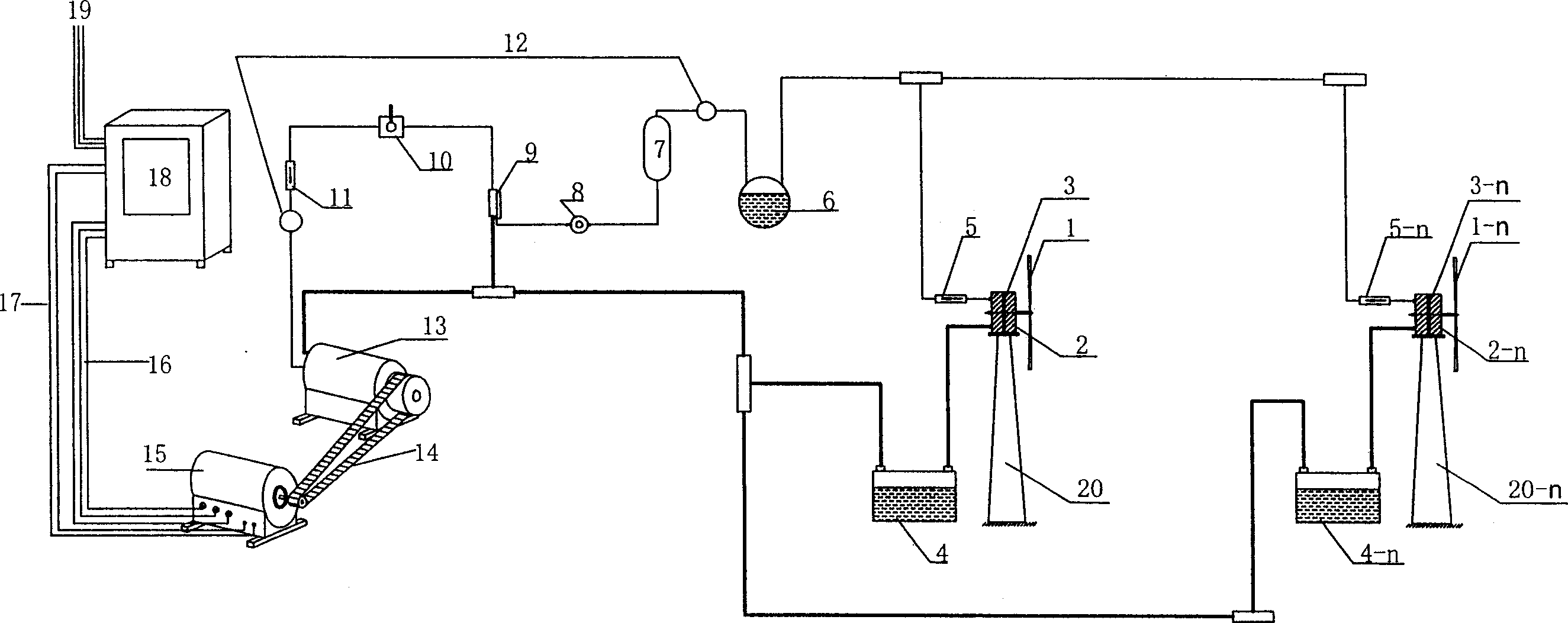

[0028]The newly developed 4 MW combined wind energy hydraulic variable power generation equipment, the maximum output power of the generator 15 is 4000kw×120%=4800kw, and the diameter of a single wind wheel is 180 meters, and four wind wheels 1 with a radius of 40 meters are now used. , drives the corresponding four high-power oil pumps 3 to work, and the output of the oil pump 3 is connected to the transmission 13 through the one-way valve 5, the pressure accumulator 6, the pressure collecting cylinder 7, and the pressure regulator 8 to provide high-pressure oil pressure for the transmission 13 , the transmission machine 13 converts the hydraulic transmission into a required constant mechanical speed output through several translational hydraulic cylinders, and then drives the generator 15 through the transmission 14 to generate three-phase alternating current. When the wind force decreased and the wind energy decreased, the hydraulic transmission power decreased. Now, the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com