Integrated sewage treating process in flocculant biological flow bed

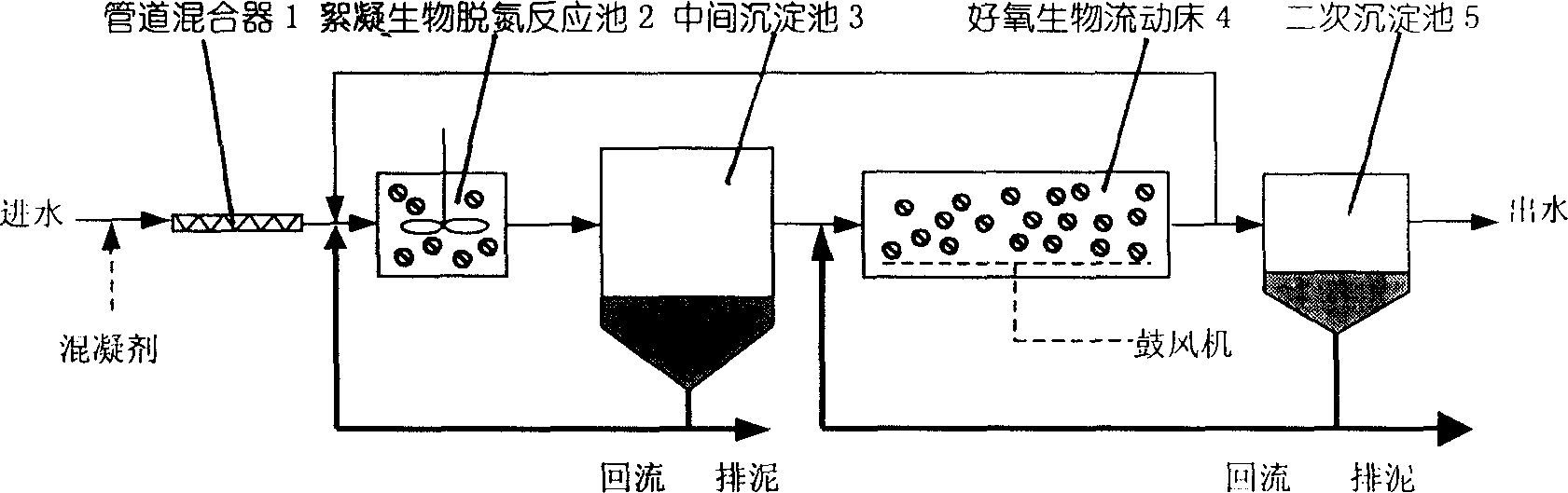

A sewage treatment and fluidized bed technology, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of insufficient denitrification carbon source, many equipment and structures, Problems such as complex process flow, to avoid insufficient denitrification carbon source, save land occupation, and achieve the effect of overall compact process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The IC-MBBR process is used to treat domestic sewage in a township. After the floating matter is removed by the grid, the sewage enters the flocculation biological denitrification reaction tank. The coagulant is PAC, the flocculant is PAM, and the pipeline is added after the pump, and the pipeline mixer is mixed. The dosage of PAC is 30mg / L, and the dosage of PAM is 1mg / L. The hydraulic retention time of the flocculation biological denitrification reaction tank is 60 minutes, mechanical stirring is used for mixing, and the filling rate is 30%. The effluent enters the intermediate sedimentation tank, and the sedimentation time is 1 hour. 30% of the produced sediment is returned to the flocculation denitrification tank, and the rest is discharged as excess sludge, and the supernatant enters the aerobic biological fluidized bed. The hydraulic retention time of the aerobic biological fluidized bed is 4 hours, the filling rate is 40%, and the dissolved oxygen is controlled ...

Embodiment 2

[0027] IC-MBBR process is used to treat domestic sewage in a tourist area. After the floating matter is removed by the grid, the sewage enters the flocculation biological denitrification reaction tank. Aluminum sulfate is selected as the coagulant, and silica gel is selected as the flocculant, which is added in the pipeline behind the pump and mixed by mechanical stirring. The dosage of aluminum sulfate is 20mg / L, and the dosage of silica gel is 0.5mg / L. The hydraulic retention time of the flocculation denitrification reaction tank is 60 minutes, mechanical stirring is used for mixing, and the filler dosage rate is 30%. The effluent enters the intermediate sedimentation tank, and the sedimentation time is 1 hour. The resulting sediment is discharged as sludge, and the supernatant enters the aerobic biological fluidized bed reaction tank. The hydraulic retention time of the aerobic biological fluidized bed is 3 hours, the filling rate is 40%, and the gas-water ratio is 4:1. 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com