Super capacitor energy accumulating and frequency varying driving electric control system for trolleybus

An electric control system and variable frequency drive technology, applied in the field of vehicles, can solve the problems of inability to realize regenerative feedback electric braking, increase visual pollution of urban space, poor flexibility and mobility, achieve good energy saving effect, reduce control The effect of safe and reliable electrical isolation between wires and terminals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

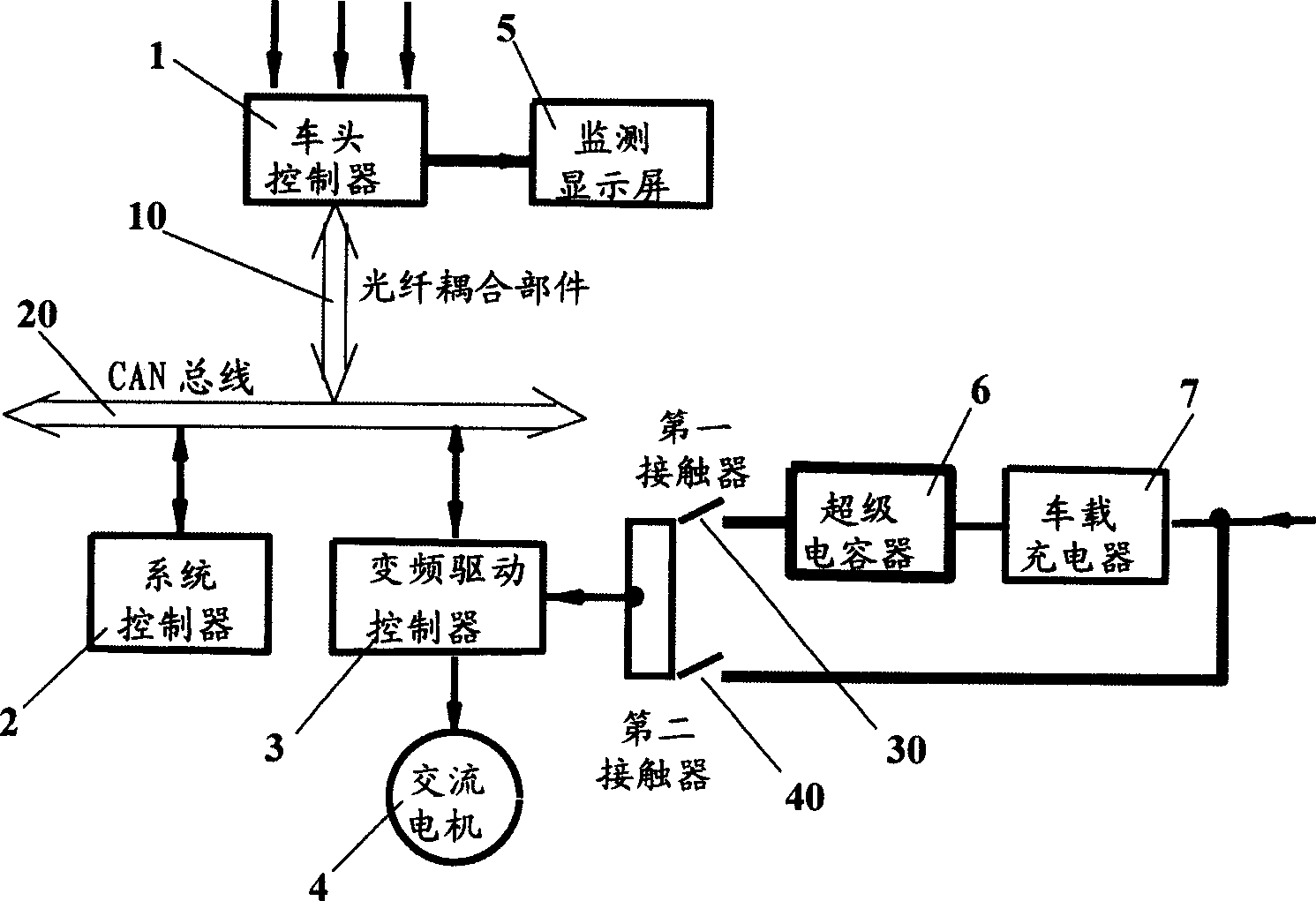

[0028] Such as figure 1 As shown, the present invention is a supercapacitor energy storage variable frequency drive electric control system for electric vehicles, which is composed of a low-voltage headstock control part and a high-voltage system control part, wherein the low-voltage headstock control part is mainly controlled by the headstock controller 1 unit, the high-voltage system control part uses the system controller 2 as the main control unit, and the head controller 1 communicates with the CAN bus 20 connected to the system controller 2 through an optical fiber coupling component 10. The feet of the tram The pedal traction master signal, the pedal brake master signal and the running state master signal are sent to the headstock controller 1, and the set value is connected with the CAN bus 20 through the optical fiber coupling part 10 The control command is transmitted to the system controller 2, and the system controller 2 performs logic state discrimination accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com